Bimetal composite pipe liquid expansion forming feeding device and process

A bimetallic composite pipe and liquid expansion technology, which is applied to metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of the impact of the feeding device, the damage of the feeding device, and the inability to determine the direction of the welding seam of the base pipe. Reduce labor intensity, improve automation, and solve the effect of welding seam orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

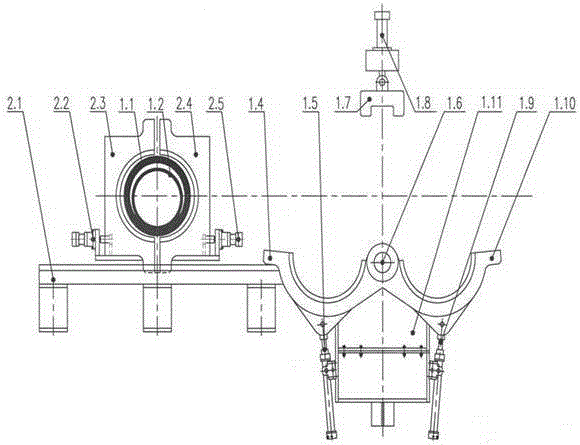

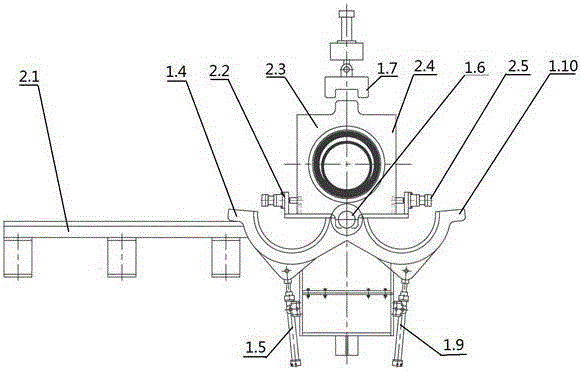

[0024] Such as figure 1 and figure 2 As shown, the present invention provides a bimetal composite pipe liquid expansion forming feeding device, including a plurality of fixed clamping devices and a plurality of movable clamping devices, the movable clamping devices and fixed clamping devices are arranged at intervals, and The axial centerlines of the movable clamping device and the fixed clamping device coincide, the base pipe 1.1 is clamped in the movable clamping device and the fixed clamping device, and the base pipe 1.1 is sleeved with a liner pipe 1.2.

[0025] The working process of the bimetal composite pipe liquid expansion forming feeding device is:

[0026] The threaded base pipe 1.1 and liner pipe 1.2 are first axially transported to the movable clamping device, and under the clamping of the movable clamping device, the threaded base pipe 1.1 and liner pipe 1.2 are then transported to the fixed Clamping device, at this time, it should be ensured that the fixed cl...

Embodiment 2

[0029] On the basis of Embodiment 1, the movable clamping device as described is composed of a left movable fixture 2.3 and a right movable fixture 2.4 located on the left and right sides of the base pipe 1.1 and arranged oppositely, and the left movable fixture 2.3 and the right movable fixture 2.4 are locked Combined to form a hollow cavity, the base pipe 1.1 is clamped in the hollow cavity, the left moving fixture driving cylinder 2.2 is installed on the left moving fixture 2.3, the right moving fixture driving cylinder 2.5 is installed on the right moving fixture 2.4, and the left moving fixture 2.3 and the right moving fixture 2.4 are all installed on the moving fixture base 2.1.

[0030] The fixed clamping device includes a fixed left clamp 1.4 and a fixed right clamp 1.10, the fixed left clamp 1.4 and the fixed right clamp 1.10 are engaged to form a hollow cavity, and the base pipe 1.1 in the hollow cavity is clamped;

[0031] The bottom ends of the fixed left clamp 1.4...

Embodiment 3

[0036] A feeding process using a bimetal composite pipe liquid expansion forming feeding device, comprising the following steps:

[0037] Step 1: Rotate the threaded base pipe 1.1 and liner 1.2 through the rotating device 1.3, so that the weld position of the base pipe 1.1 faces upward;

[0038] Step 2: Move at least two movable clamping devices to the loading station, open the left movable fixture 2.3 and the right movable fixture 2.4, put the base pipe 1.1 in, close the left movable fixture 2.3 and the right movable fixture 2.4, and make the base pipe 1.1 Located in the hollow cavity formed when the left moving fixture 2.3 and the right moving fixture 2.4 are engaged, the base pipe 1.1 is clamped;

[0039] Step 3: Separate the movable clamping device clamping the base pipe 1.1 from the movable clamping base 2.1, and the movable clamping device clamping the base tube 1.1 is transported axially to move to the water pressure with multiple fixed clamping devices. In the expansi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com