Guide control mechanism for pneumatic lifting table

A technology of pneumatic lifting and guiding control, which is applied to desks, desks, and mechanical equipment that can change the height of the desk. , the effect of high guiding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

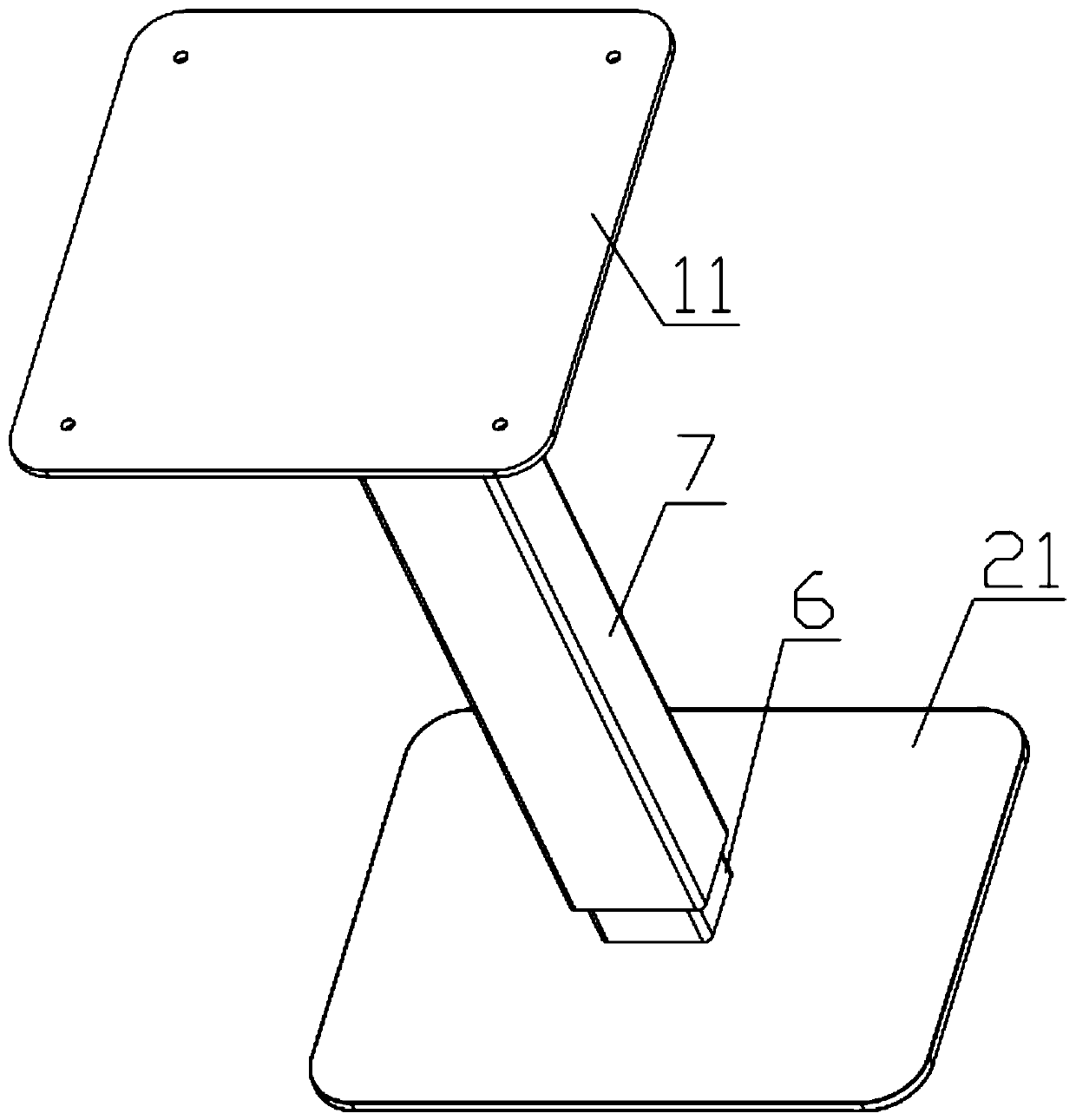

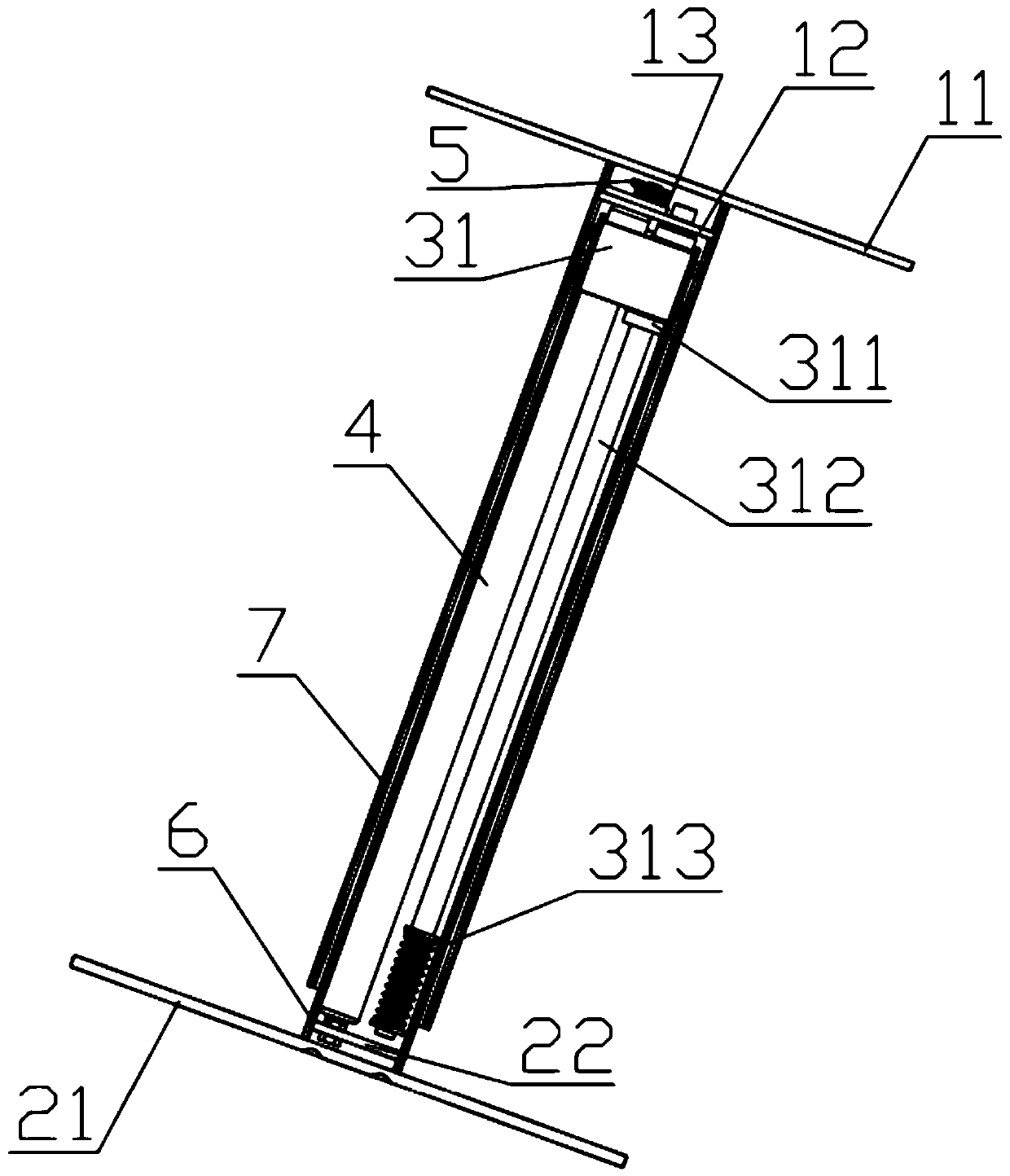

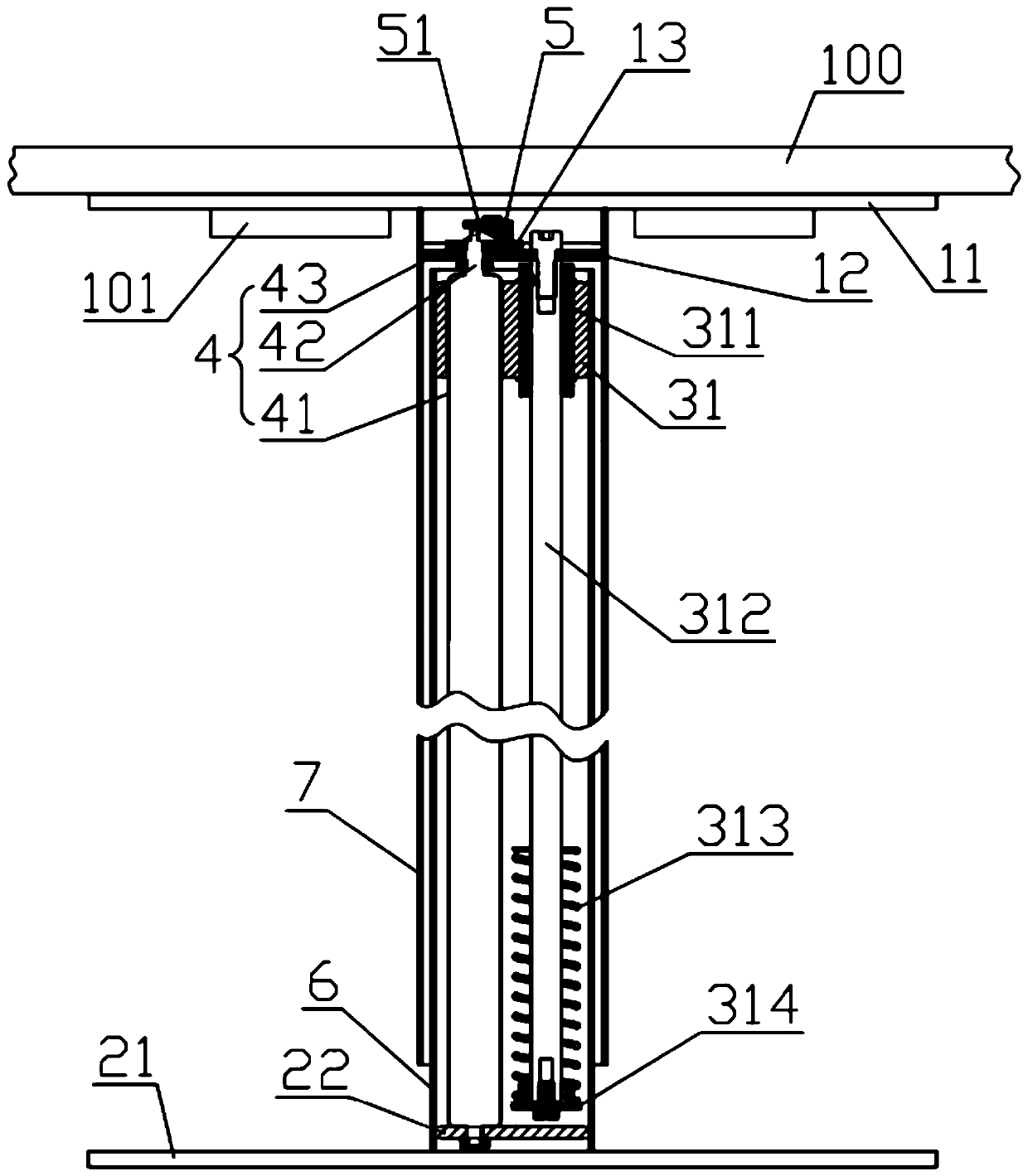

[0036] Such as Figures 1 to 3 As shown, the guide control mechanism of the pneumatic lift table according to one embodiment of the present invention includes a desktop support plate 11 , a lower bottom plate 21 , an upper fixing block 31 , a lockable gas spring 4 and a wedge switch 5 . The shape structure of the upper fixing block 31 can adopt a rectangular structure or a circular structure, and this embodiment adopts a rectangular structure. The upper fixed block 31 is fixedly sleeved on the upper end of the cylinder 41 of the lockable gas spring 4, the bottom of the cylinder 41 of the lockable gas spring 4 is connected with the lower connecting plate 22 and locked with a nut, the piston rod 42 of the lockable gas spring 4 The upper end portion is fixedly connected with an upper connecting plate 12 . A first linear bearing 311 is fixedly installed in the upper fixing block 31 , and a first linear optical axis 312 matched with it is placed in the first linear bearing 311 . ...

Embodiment 2

[0044] Such as Figure 7 and 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that there are three sets of guides for the first linear optical axis 312 . Specifically, the first linear optical axis 312 is provided with three groups, the first linear bearing 311 matched with the first linear optical axis 312, and the first cylindrical coil spring 313 sleeved on the first linear optical axis 312 are all There are three groups, and on the upper fixing seat, the three groups of first linear bearings 311 are evenly distributed around the lockable gas spring 4 . In practical application, the guiding mechanism can also be two sets, that is, there are two sets of the first linear optical axis 312 , the first linear bearing 311 and the first cylindrical coil spring 313 . In this embodiment, the upper fixing block 31 adopts a circular structure, and the upper free end of the first cylindrical coil spring 313 is also clamped with a spring seat 314 . The first linear...

Embodiment 3

[0046] Such as Figure 11 , 12 As shown in and 15, the guide control mechanism of the pneumatic lifting table according to one embodiment of the present invention includes a desktop support plate 11, a lower bottom plate 21, an upper fixing block 31, a lower fixing block 32, an outer step tube 44, and a lockable gas spring 4. Wedge switch 5, outer sleeve 7, middle sleeve 8, inner sleeve 6, upper support rod 315 and lower support rod 325. In this embodiment, the outer structure of the upper fixing block 31 and the lower fixing block 32 adopts a cylindrical structure.

[0047]The cylinder barrel 41 of the lockable gas spring 4 is placed in the outer step tube 44, and the upper and lower ends of the outer step tube 44 are provided with steps, and the upper fixing block 31 and the lower fixing block 32 are respectively installed on the upper and lower ends of the outer step tube 44. superior. The upper fixed block 31 and the lower fixed block 32 installed on the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com