Incense and preparation method thereof

A technology for fragrant materials and base materials, applied in the field of fragrant materials and their preparation, can solve the problems of human carcinogenic respiratory diseases, poor heat dissipation efficiency of products, air pollution, etc., to reduce the possibility of being scalded, improve human inhalation hazards, Fast cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above content of the present invention more obvious and easy to understand, the following specific examples are given. The present invention is related to a kind of fragrance material and its preparation method. The fragrance material formed by the steps of its preparation method will be described in detail below, and the fragrance material It is composed of base material coated with fragrance body.

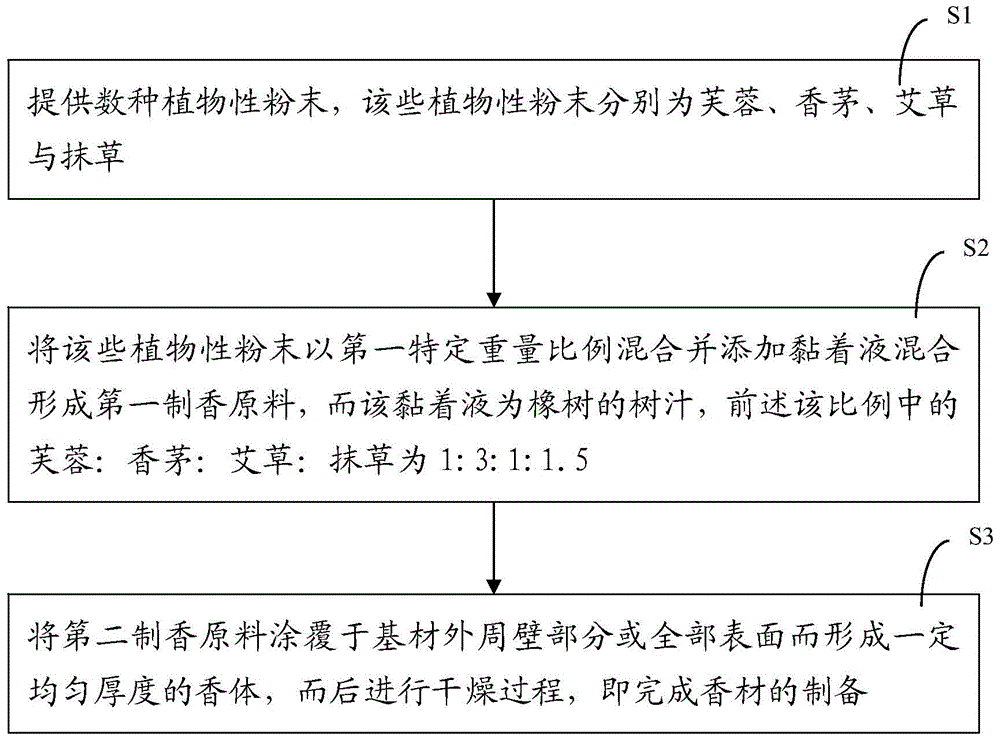

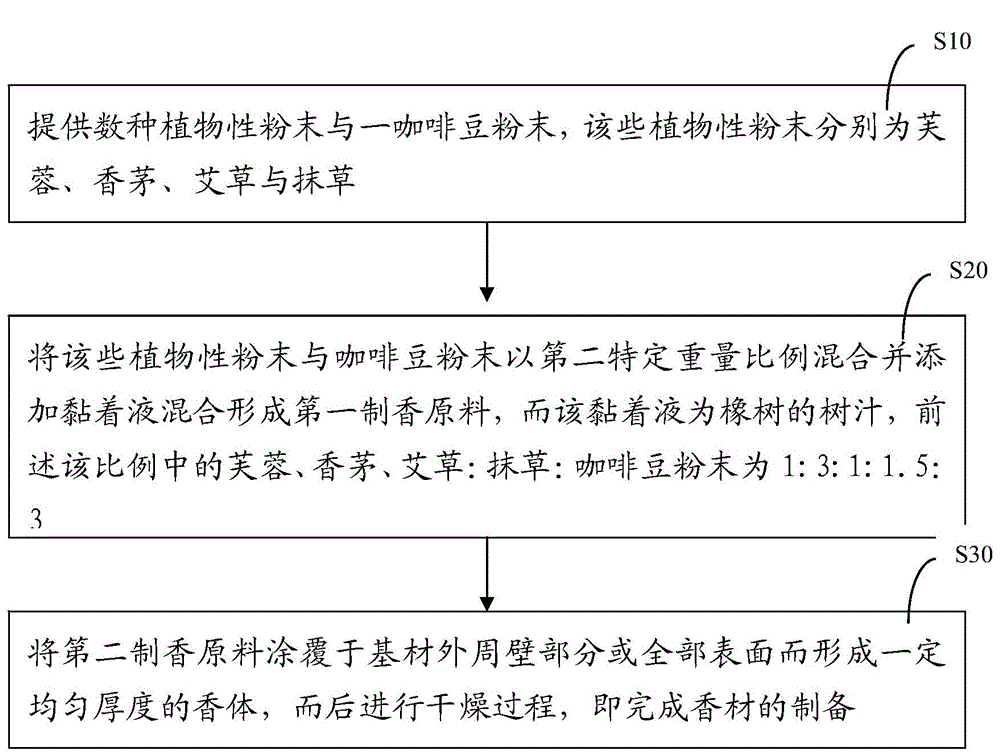

[0019] Please cooperate with reference Figure 1A Shown, the preparation method of fragrant material of the present invention, it comprises the following steps:

[0020] S1: providing the first vegetable powder, the second vegetable powder, the third vegetable powder and the fourth vegetable powder;

[0021] S2: Mix the above-mentioned botanical powders in a first specific weight ratio to form a first fragrance-making raw material;

[0022] S3: Provide a substrate, partially or completely coat an adhesive liquid on the peripheral wall of the substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com