Continuous-foamed diving suit cloth and manufacture method thereof

A manufacturing method and technology for diving suits, which can be applied to protective clothing, special outerwear, clothing, etc., can solve the problems such as the weight of the material and the characteristics of flame resistance, the diver's easy cold feeling, material loss, etc., and achieve the best heat preservation effect, good flame resistance, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

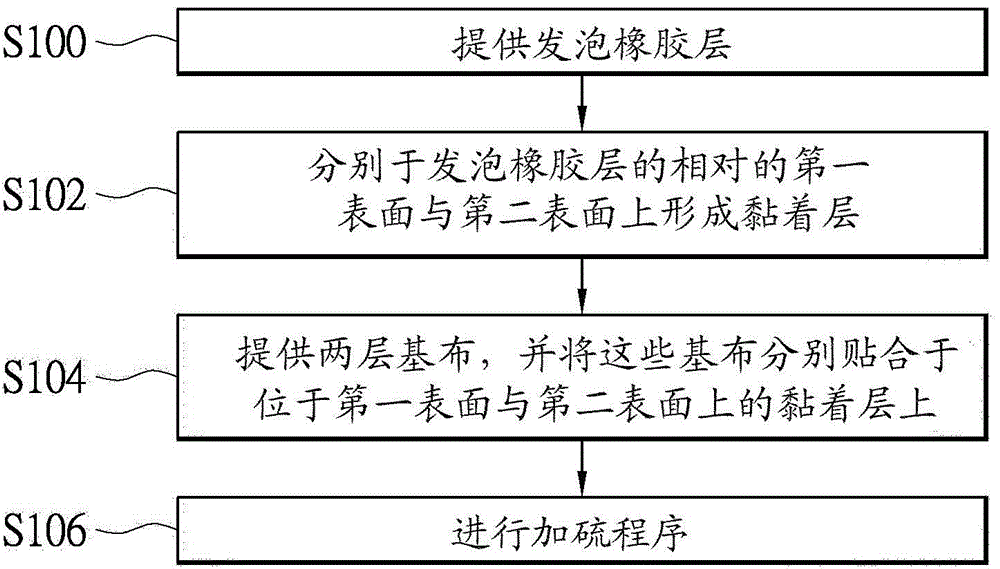

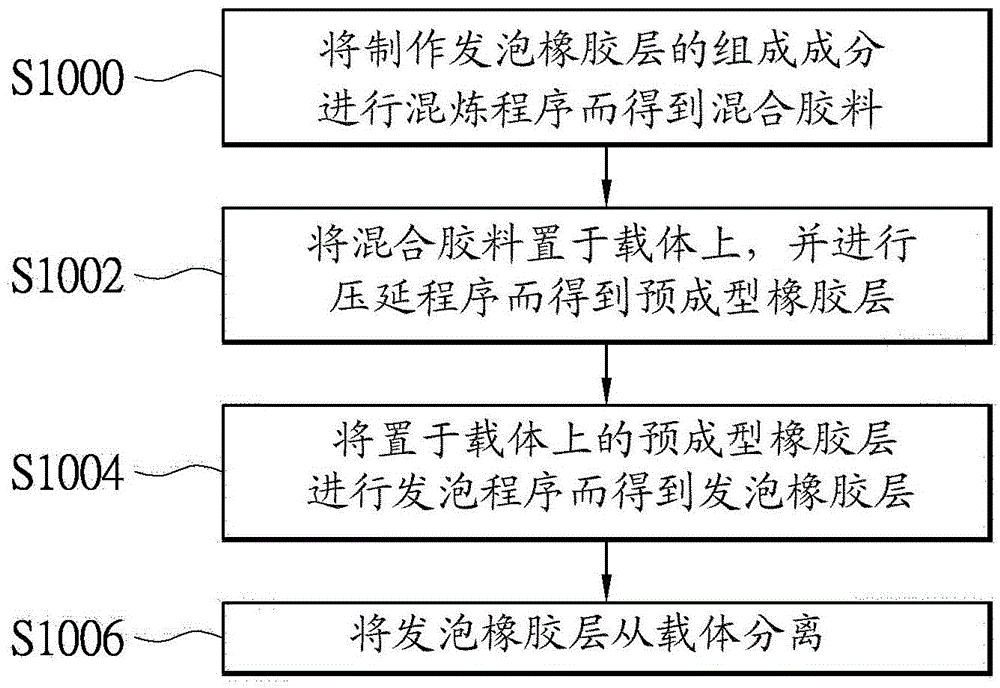

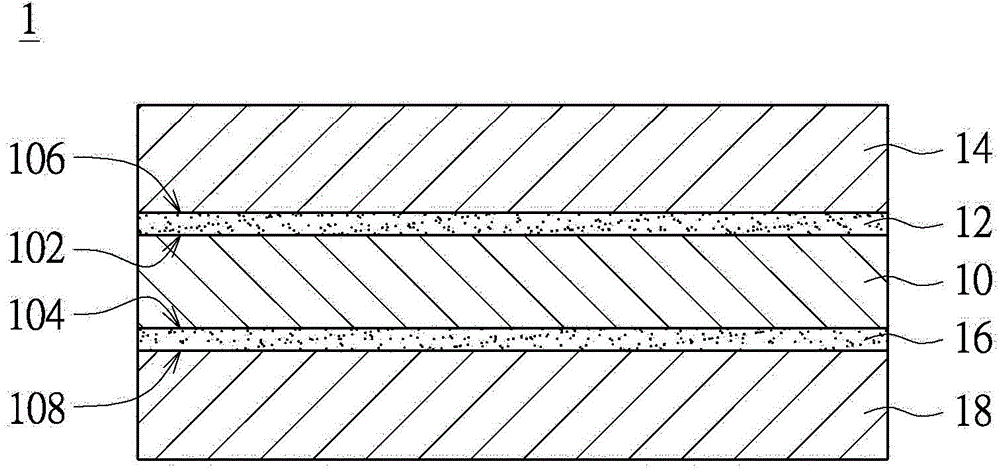

[0024] Please refer to figure 1 , is a schematic flow chart of a continuous foaming wetsuit fabric manufacturing method according to an embodiment of the present invention. Such as figure 1 As shown, the continuous foaming diving suit cloth manufacturing method of the present embodiment comprises the following steps:

[0025] First, as shown in step S100 , a foam rubber layer 10 is provided. The composition of the foam rubber layer 10 includes 100 parts by weight of main rubber, 10 to 20 parts by weight of filler, 10 to 20 parts by weight of far-infrared ore powder and 30 to 45 parts by weight of flame retardant.

[0026] Specifically, in the composition of the above-mentioned foam rubber layer 10, the main rubber includes chlorobutyl rubber, the filler includes clay, and the flame retardant includes 20 to 30 parts by weight of aluminum hydroxide (H 3 AlO 3 ) and 10 to 15 parts by weight of antimony trioxide (Sb 2 o 3 ). In addition, the composition of the foam rubber l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com