Titanium dioxide nanotube/polyaniline composite electrode, preparation and application thereof

A technology of titanium dioxide and composite electrodes, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of poor electrochemical stability, achieve improved conductivity, good conductivity, and increased reactive sites Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of titanium dioxide nanotubes by anodic oxidation method:

[0027] Use a high-purity titanium sheet with a size of 13×10mm, a thickness of 1mm, and a purity of 99.99% as the substrate. Before oxidation, the titanium sheet is mechanically polished with 600 mesh and 1500 mesh sandpaper, and then 1wt% HF and 3wt% HNO 3 Aqueous solution is used for chemical polishing; the polished titanium sheet is used as the working electrode, and the platinum electrode is used as the counter electrode. 4 In the ethylene glycol solution of F and 2vol% deionized water, oxidize at a voltage of 60V for 2h, and remove the oxide film by ultrasonic; 4 F, 0.5 wt% H 3 PO 4 and 2vol% deionized water in an ethylene glycol solution for the second oxidation, the oxidation voltage is 60V, and the oxidation time is 30min; then it is placed in a high-temperature furnace with a hydrogen atmosphere and calcined at a temperature of 450°C for 2h to obtain titanium dioxide nanotubes ;

...

Embodiment 2

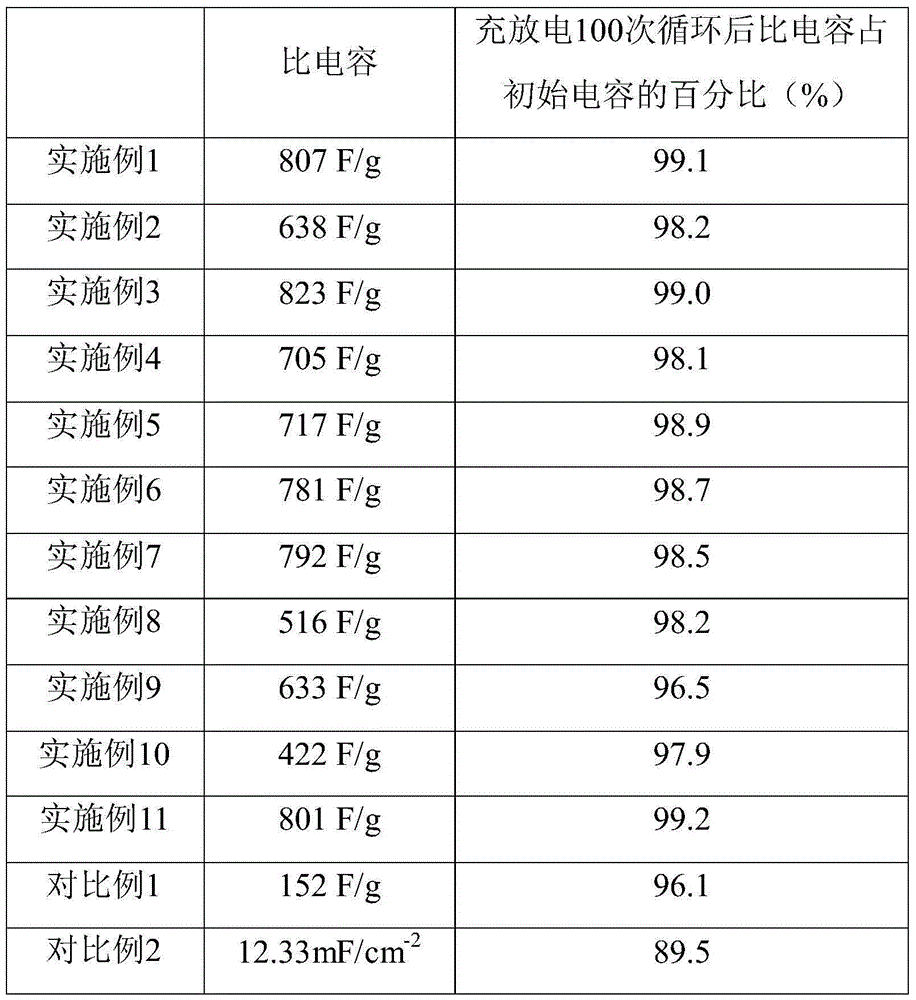

[0033] Compared with Example 1, the preparation of a titanium dioxide nanotube / polyaniline composite electrode in this example is different in that the electropolymerization time in step (2) is 1 min, and the rest are identical. Table 1 shows the charge and discharge test results of the titanium dioxide nanotube / polyaniline composite electrode obtained in this example.

Embodiment 3

[0035] Compared with Example 1, the preparation of a titanium dioxide nanotube / polyaniline composite electrode in this example is different in that the electropolymerization time of step (2) is 15 minutes, and the rest are identical. Table 1 shows the charge and discharge test results of the titanium dioxide nanotube / polyaniline composite electrode obtained in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com