Nanometer screen window for preventing PM2.5 and method for preparing screen window material

A screen and nano technology, applied in the field of environmental protection equipment, can solve problems such as unfavorable popularization and application, poor stability, complicated process, etc., and achieve the effects of not easy to fall off, easy to produce and transport, and prolong life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

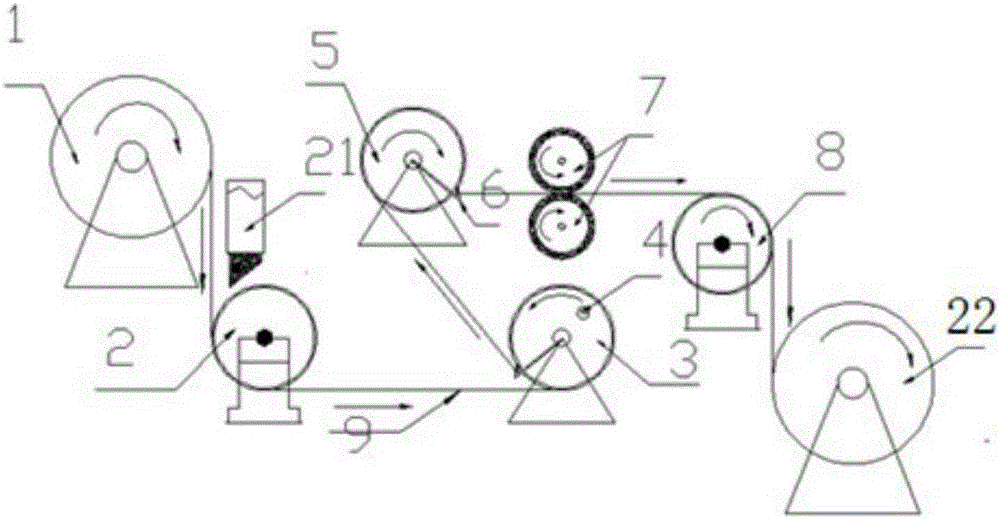

[0035] The present embodiment relates to a kind of anti-PM2.5 nano screen window (NSW-2.5); figure 1 As shown, the anti-PM2.5 nano-screen window includes a window frame 14 and a nano-screen material fixed on the window frame 14, and the nano-screen material includes a nanofiltration membrane 15 and a film carrier 17, and the nanofiltration membrane 15 is made of dispersed The short filaments of nano-acetate fibers are solidified and glued to the surface of the film carrier 17 (carbon-clamped non-woven fabric).

[0036] In this embodiment, the nano-screen window also includes detachable window strips 13 arranged around the window frame 14, the window strips 13 are provided with several circular grooves 16, and the window frame 14 is provided with several The convex groove 20 that matches the circular groove 16.

[0037]When assembling, the nano-screen window material prepared by the present embodiment is placed between the window frame 14 and the window bar 13, and a circular ...

Embodiment 2

[0053] In this embodiment, the window frame 14 , the nanofiltration membrane 15 , the membrane carrier 17 and the installation methods are the same as those in Embodiment 1, and will not be repeated here. The difference is that a slight improvement is made on the basis of the process in Example 1.

[0054] In order to strengthen the bonding degree of the carbon interlaced non-woven fabric, the strong curing glue and the nano-acetate fiber, the outer surfaces of the first transition roller, the high-pressure roller, the vacuum roller, the hot compaction roller and the second transition roller are all made of ceramic materials, The thermal conductivity of the ceramic material is 20-30W / M.K; the withstand voltage is 10KV; the temperature resistance is 1000 degrees. And the outer surface temperature of the first transition roller, high pressure roller, vacuum roller, hot compaction roller and second transition roller is controlled at 300° C. by electric heating (external heating d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com