Methanation method of heavy hydrocarbon

A technology for heavy hydrocarbons and methane, applied in the petrochemical field, can solve the problems of large hydrogen consumption and high hydrogen source cost, and achieve the effect of reducing the value of residual carbon, reducing emissions and reducing the cost of refineries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

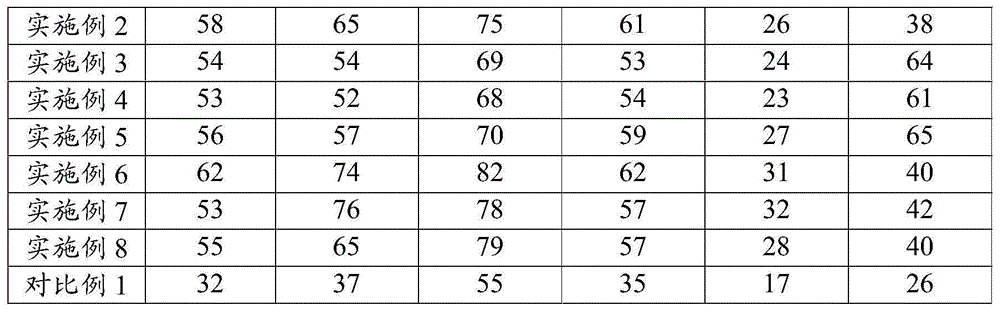

Examples

Embodiment 1

[0032] A method for adding methane to heavy hydrocarbons:

[0033] The raw material is Kuwait atmospheric residue, the reactor is a fixed bed, and the reaction conditions are as follows:

[0034] The reaction temperature is 450°C, the reaction pressure is 15Mpa, and the feed volume space velocity is 1.5h -1 , the volume ratio of methane to heavy hydrocarbons is 400, and the volume ratio of methane activation catalyst to hydrogenation catalyst is 1:200.

[0035] The hydrogenation catalyst is an atmospheric residue hydrogenation catalyst produced by Sinopec Fushun Petrochemical Research Institute. The methane activation catalyst carrier is alumina, the active component is molybdenum, and the mass percentage of the active component in the methane activation catalyst is 2%,

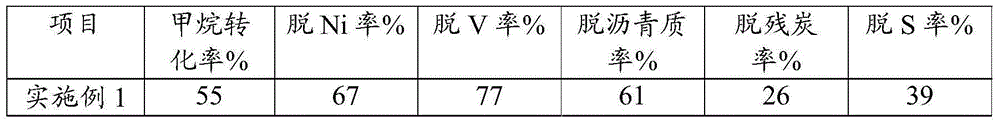

[0036] The properties of the Kuwaiti atmospheric residue are as follows:

[0037] Table 1 Kuwait Atmospheric Residue Property Data Table

[0038] raw material name

Embodiment 2

[0040] A method for adding methane to heavy hydrocarbons:

[0041] Using the same method as in Example 1, the difference is that the reaction temperature is 300°C, the reaction pressure is 2Mpa, and the feed volume space velocity is 0.5h -1 , the volume ratio of methane to heavy hydrocarbons is 300, the volume ratio of methane activation catalyst to hydrogenation catalyst is 1:10, the carrier of methane activation catalyst is silicon oxide, the active component is nickel, and the active component content is methane activation catalyst 1% of mass.

Embodiment 3

[0043] A method for adding methane to heavy hydrocarbons:

[0044]Using the same method as in Example 1, the difference is that the reaction temperature is 700°C, the reaction pressure is 28Mpa, and the feed volume space velocity is 4.5h -1 , the volume ratio of methane to heavy hydrocarbons is 5500, the volume ratio of methane activation catalyst to hydrogenation catalyst is 1:200, the carrier of methane activation catalyst is HZSM-5 molecular sieve, the active component is iron, and the active component content is methane Activate 25% of the mass of the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com