A kind of digital inkjet printing material and preparation method thereof

A technology of digital inkjet printing and printing materials, which is applied in the field of advertising display and decorative materials, can solve the problems of unguaranteed picture quality, complicated preparation process, and fading of inkjet patterns, and achieves improved anti-ultraviolet and heat-oxidative aging resistance. Preparation method Simple, high softening point temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

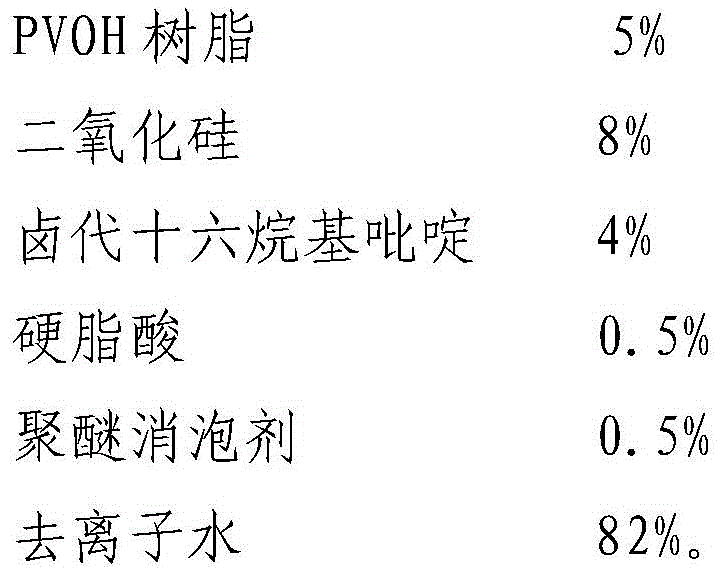

Embodiment 1

[0035] 1) Preparation of special hot melt adhesive for digital inkjet printing:

[0036] According to parts by weight, weigh the following components,

[0037] 70 parts of PVC resin, 25 parts of plasticizer (DOP), 5 parts of composite ultraviolet absorber (the weight ratio of HALS and UV-328 is 1:9), 5 parts of antioxidant 1010, 0.6 parts of defoamer, hard 4 parts of fatty acid, 10 parts of calcium zinc stabilizer, 100 parts of ethyl acetate. Add ethyl acetate, PVC resin, plasticizer DOP, composite ultraviolet absorber, antioxidant 1010, stearic acid, calcium zinc stabilizer into the polymerization kettle and stir and mix, add defoamer to defoam during the stirring process, static Set, filter, detect, reserve.

[0038] The solid content of the prepared hot melt adhesive is 40%, the softening point temperature is 78°C, the melt flow index is 140g / 10min (200°C), the apparent viscosity is 5600MPa.S, the bonding strength is 2.5Kg / 25mm, and the peel strength is 192N / cm.

[003...

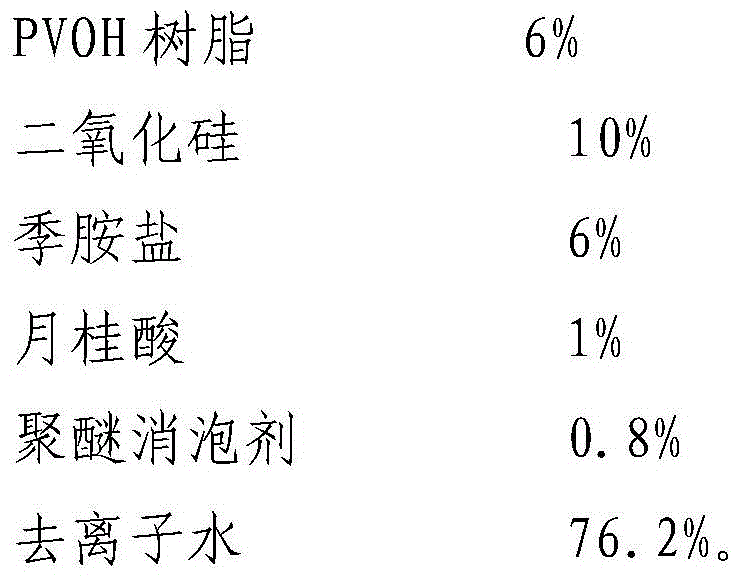

Embodiment 2

[0050] 1) Preparation of special hot melt adhesive for digital inkjet printing:

[0051] According to parts by weight, weigh the following components,

[0052] 66 parts of PVC resin, 23 parts of plasticizer (DOP), 4 parts of composite ultraviolet absorber (the weight ratio of HALS and UV-328 is 1:8), 4 parts of antioxidant 1010, 1.5 parts of defoamer, hard 3 parts of fatty acid, 15 parts of calcium zinc stabilizer, 95 parts of butanone. Add methyl ethyl ketone, PVC resin, plasticizer DOP, composite ultraviolet absorber, antioxidant 1010, stearic acid, calcium zinc stabilizer into the polymerization kettle, stir and mix, add defoamer to defoam during the stirring process, and let stand , filtering, detection, backup.

[0053] The solid content of the prepared hot melt adhesive is 38%, the softening point temperature is 82°C, the melt flow index is 130g / 10min (200°C), the apparent viscosity is 5100MPa.S, the bond strength is 2.1Kg / 25mm, and the peel strength is 158N / cm.

[...

Embodiment 3

[0063] 1), the preparation of special hot melt adhesive for digital inkjet printing is the same as in Example 1.

[0064] 2), the preparation of the ink-absorbing material is the same as in Example 2.

[0065] 3), the preparation of digital inkjet printing materials:

[0066] Put the PP base material on the roller shaft of the adhesive machine and unwind it. The unwinding tension is 15N. The surface of the base material is treated with corona. The high-frequency AC voltage used for corona treatment is 10000V / m 2 ;

[0067] Coat 25 μm of special hot melt adhesive for digital inkjet printing on the surface of the substrate, dry at 80°C, and cool down; coat 35 μm thick ink-absorbing material on the surface of the cooled special hot melt adhesive for digital inkjet printing, dry, and cool down;

[0068] Spray the pattern on the surface of the ink-absorbing material, cover the surface of the pattern with a release film, and press the substrate downward for 20 seconds at 160°C and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com