Flame-retardant polyamide and preparation method and application thereof

A flame retardant and reactive flame retardant technology, applied in the field of flame retardant polyamide and its preparation, can solve problems such as blending of synergistic flame retardants, and achieve the effects of good water solubility, ensuring solubility and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

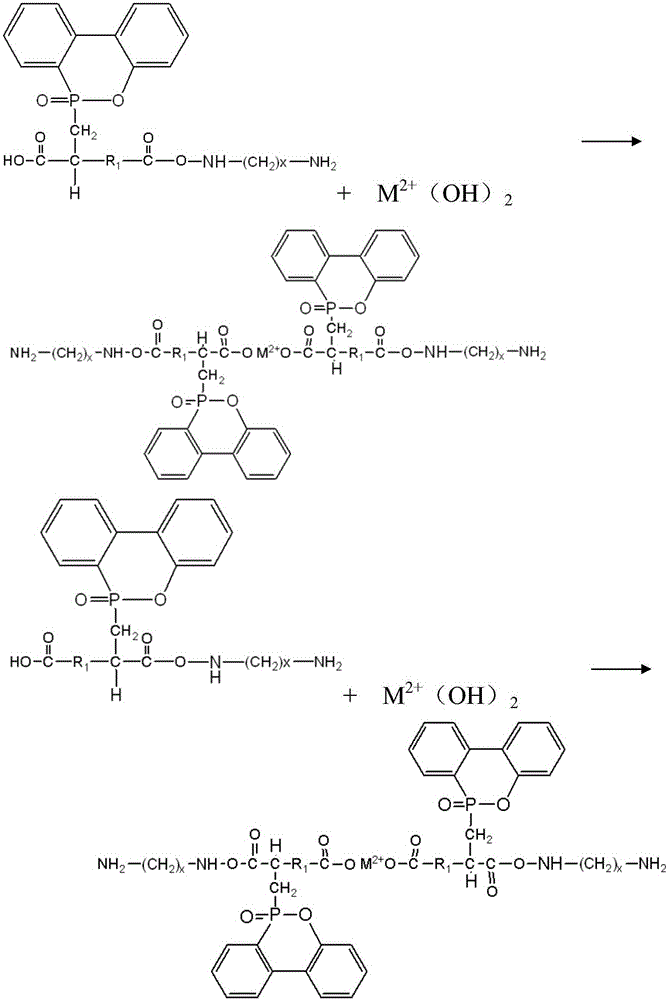

[0056] Example 1. Preparation of flame retardant polyamide based on reactive calcium ion salt flame retardant:

[0057] 1) First, prepare a reactive water-soluble flame retardant, add itaconic acid and hexamethylenediamine in a molar ratio of 1:1 into a four-necked flask with a stirrer, a thermometer, a reflux condenser and a nitrogen pipe, Nitrogen gas was introduced to react the two in water at 60°C for 0.5h to obtain an aqueous solution of hexamethylenediamine itaconate; -6-Oxide (DOPO) was slowly added to the aqueous solution of hexamethylenediamine itaconate, so that the molar ratio of DOPO and hexamethylenediamine itaconate was 1:1, reflux at 90°C for 2.5h, and cool to room temperature , filter the reaction product, dissolve and recrystallize with deionized water 5 times to remove impurities, and dry to obtain a reactive water-soluble flame retardant, which is the compound shown in formula 5 and / or formula 6, wherein, R 1 Be methylene; x is 6;

[0058] press again fi...

Embodiment 2

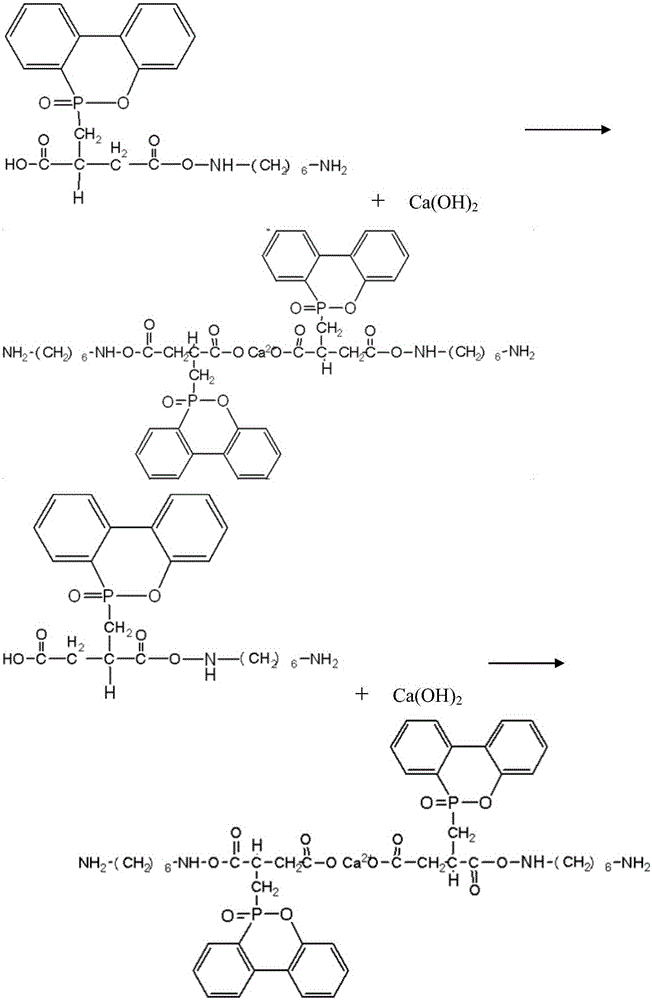

[0065] Example 2. Preparation of flame retardant polyamide based on reactive magnesium ion salt flame retardant:

[0066] 1) First, prepare a reactive water-soluble flame retardant, add itaconic acid and hexamethylenediamine in a molar ratio of 1:1 into a four-necked flask with a stirrer, a thermometer, a reflux condenser and a nitrogen pipe, Nitrogen gas was introduced to react the two in water at 60°C for 0.5h to obtain an aqueous solution of hexamethylenediamine itaconate; -6-Oxide (DOPO) was slowly added to the aqueous solution of hexamethylenediamine itaconate, so that the molar ratio of DOPO and hexamethylenediamine itaconate was 1:1, reflux at 90°C for 2.5h, and cool to room temperature , filter the reaction product, dissolve and recrystallize with deionized water 5 times to remove impurities, and dry to obtain a reactive water-soluble flame retardant, which is the compound shown in formula 5 and / or formula 6, wherein, R 1 Be methylene; x is 6;

[0067] press again ...

Embodiment 3

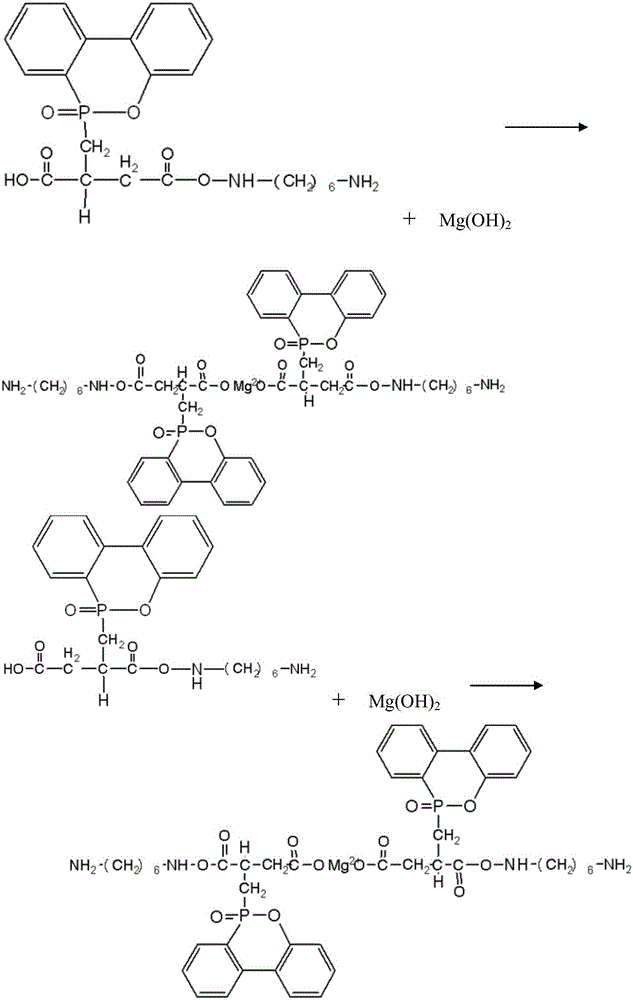

[0073] Example 3. Preparation of flame retardant polyamide based on reactive magnesium ion salt flame retardant:

[0074] 1) First, prepare a reactive water-soluble flame retardant, add itaconic acid and hexamethylenediamine in a molar ratio of 1:1 into a four-necked flask with a stirrer, a thermometer, a reflux condenser and a nitrogen pipe, Nitrogen gas was introduced to react the two in water at 60°C for 0.5h to obtain an aqueous solution of hexamethylenediamine itaconate; -6-Oxide (DOPO) was slowly added to the aqueous solution of hexamethylenediamine itaconate, so that the molar ratio of DOPO and hexamethylenediamine itaconate was 1:1, reflux at 90°C for 2.5h, and cool to room temperature , filter the reaction product, dissolve and recrystallize with deionized water 5 times to remove impurities, and dry to obtain a reactive water-soluble flame retardant, which is the compound shown in formula 5 and / or formula 6, wherein, R 1 Be methylene; x is 6;

[0075] press again ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com