Coal-gangue lightweight aggregate concrete

A technology of lightweight aggregate concrete and coal gangue, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of floating and compressive strength that do not meet the concrete compressive standard, and achieve self-weight reduction, Low elastic modulus, effect of reducing foundation load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] A coal gangue lightweight aggregate concrete is made by mixing water, cement, coal gangue aggregate, coal gangue sand, water reducing agent and silica fume;

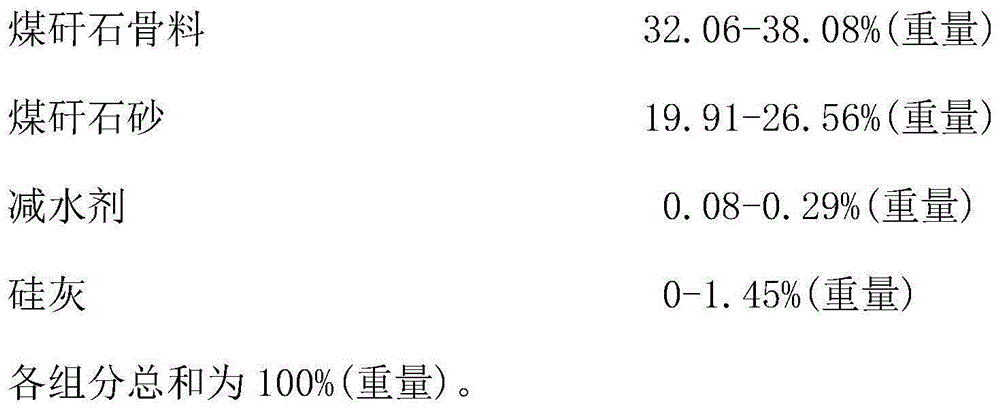

[0011] The added weight of each component is:

[0012]

[0013] The compression test result after 24 hours of steam curing is 16.6Mpa;

[0014] A kind of preparation method of coal gangue lightweight aggregate concrete:

[0015] 1. Weigh 2.6kg of water and add 0.013kg of water reducer to the water and stir evenly;

[0016] 2. Pour 6.47kg of gangue aggregate, 3.39kg of gangue sand, and 4.55kg of cement into a 30-liter mixer and stir evenly;

[0017] 3. Pour in 2.6kg of water and stir, and stand still for one minute every two or three minutes to fully absorb the water. After stirring three times, it can be formed;

[0018] 4. The mold can be removed after 24 hours.

Embodiment 2

[0020] A coal gangue lightweight aggregate concrete is made by mixing water, cement, coal gangue aggregate, coal gangue sand, water reducing agent and silica fume;

[0021] The added weight of each component is:

[0022]

[0023] The compression test result after 24 hours of steam curing is 20.8Mpa;

[0024] A kind of preparation method of coal gangue lightweight aggregate concrete:

[0025] 1. Weigh 2.3kg of water and add 0.05kg of water reducer to the water and stir evenly;

[0026] 2. Pour 6.47kg of gangue aggregate, 3.39kg of gangue sand, and 4.55kg of cement into a 30-liter mixer and stir evenly;

[0027] 3. Pour in 2.3kg of water and stir, and stand still for one minute every two or three minutes to fully absorb the water. After stirring three times, it can be formed;

[0028] 4. The mold can be removed after 24 hours.

Embodiment 3

[0030] A coal gangue lightweight aggregate concrete is made by mixing water, cement, coal gangue aggregate, coal gangue sand, water reducing agent and silica fume;

[0031] The added weight of each component is:

[0032]

[0033] The compression test result after 24 hours of steam curing is 24.1Mpa;

[0034] A kind of preparation method of coal gangue lightweight aggregate concrete:

[0035] 1. Weigh 2.4kg of water and add 0.035kg of water reducer to the water and stir evenly;

[0036] 2. Pour 5.51kg of gangue aggregate, 4.22kg of gangue sand, and 4.77kg of cement into a 30-liter mixer and stir evenly;

[0037] 3. Pour in 2.4kg of water and stir, and stand still for one minute every two or three minutes to fully absorb the water. After stirring three times, it can be formed;

[0038] 4. The mold can be removed after 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com