Potassium ferrate slow-release composite material as well as preparation method and use thereof

A technology of potassium ferrate and composite materials, applied in biological sludge treatment, oxidation treatment of sludge, etc., can solve the problems of unsuitable long-term treatment of organic pollutants in sediment, high long-term operation cost, short action time, etc., and achieve improved Self-purification ability of water body, low cost and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The masses of fixed paraffin and potassium ferrate were 2g and 4g, respectively.

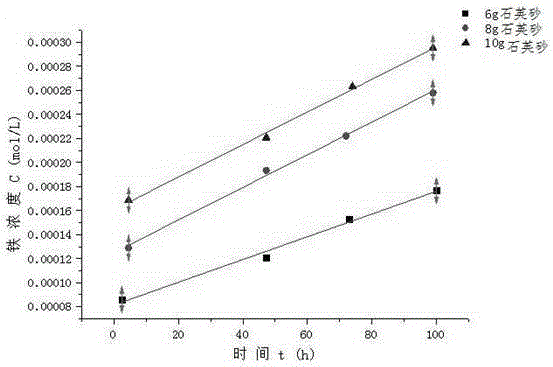

[0051] Weigh 6g, 8g, and 10g of quartz sand, respectively, and add them into containers filled with potassium ferrate, stir and mix evenly. Heat the beaker containing paraffin in a constant temperature water bath at 70°C. After the paraffin is completely melted, pour in the mixed quartz sand potassium ferrate mixture, stir until the mixture is completely soaked in paraffin, and quickly pour it into φ20mm×50mm while it is hot Compact in a cylindrical mold, and take it out after it is cooled and formed, and then the potassium ferrate slow-release composite materials with different quartz sand contents are obtained, and the numbers are slow-release composite materials S1 (6g quartz sand), S2 (8g quartz sand) , S3 (10g quartz sand).

[0052] In order to verify that the slow-release composite material containing different qualities of quartz sand has a slow-release effect, the iron release ra...

Embodiment 2

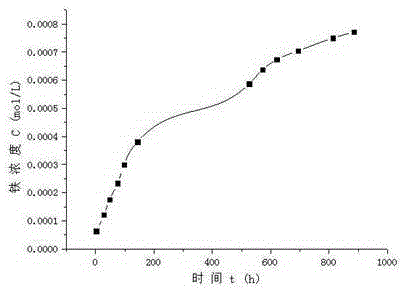

[0055] The mass of fixed paraffin and quartz sand is 2g and 10g respectively.

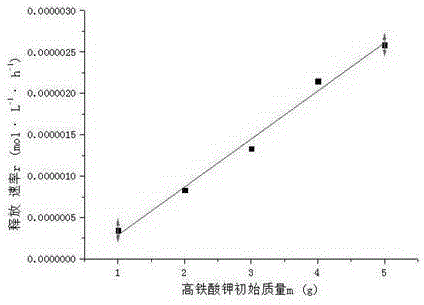

[0056] Weigh 1g, 2g, 3g, 4g, 5g of potassium ferrate respectively, add them into the container filled with quartz sand, stir and mix evenly. Heat the beaker containing paraffin in a constant temperature water bath at 70°C. After the paraffin is completely melted, pour in the mixed quartz sand and potassium ferrate mixture, stir until the mixture is completely soaked in paraffin, and quickly pour it into the φ20mm × Compact in a cylindrical mold of 50 mm, and take it out after it is cooled and formed to prepare potassium ferrate slow-release composite materials containing potassium ferrate of different qualities. Take the number as G1 (1g potassium ferrate), G2 (2g potassium ferrate), G3 (3g potassium ferrate), G4 (4g potassium ferrate), G5 (5g potassium ferrate).

[0057] In order to verify that the slow-release composite material containing different qualities of potassium ferrate has a slow-rele...

Embodiment 3

[0061] The organic matter in the bottom mud has complex components and many types. In this example, trichlorethylene (TCE), a relatively common organic pollutant whose content can be easily measured, was selected as the treatment object of the potassium ferrate slow-release composite material. In view of the large variety of organic matter in the sediment, which is difficult to measure individually and the need to maintain the measuring instrument, an aqueous solution containing TCE was used to simulate the sediment of rivers and lakes polluted by organic matter to explore the treatment effect of potassium ferrate slow-release composite materials on TCE.

[0062] Weigh 2.5g of potassium ferrate powder and put it into 250mL Erlenmeyer flask with an initial concentration of TCE of 20mg / L, stir the reaction in a magnetic stirrer and take a sample every 1h, and use high performance liquid chromatography to determine the remaining content of TCE. The experimental results show that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com