Double-component polyurethane waterproof coating structure

A two-component polyurethane and waterproof coating technology, applied in coatings, asphalt layered products, layered products, etc., can solve problems such as endangering people's health and environmental pollution, and achieve simple structure, strong impact resistance, and water tightness high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

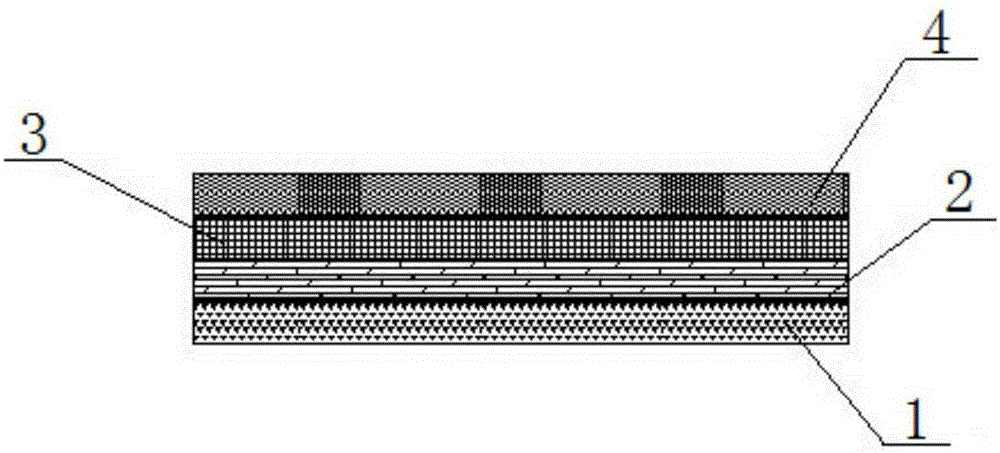

[0016] Such as figure 1 As shown, a two-component polyurethane waterproof coating structure of the present invention includes a base layer 1, an adhesive layer 2, a spacer layer 3 and a waterproof layer 4; the base layer 1 is arranged at the bottom, and the adhesive layer 2 is arranged on the base layer 1, the spacer layer 3 is set on the adhesive layer 2, and the waterproof layer 4 is set on the spacer layer 3. The base layer 1 is made of metal or non-metal material. The adhesive layer 2 is a modified epoxy resin material. The spacer layer 3 is a nano-material with a double-layer protrusion structure on the surface. The waterproof layer 4 is a two-component polyurethane coating composed of two main components: prepolymer and coal tar-free asphalt paste, and other auxiliary agents and additives.

[0017] The base layer 1 is made of metal or non-metal material, which broadens the installation scope of this structure. Adhesive layer 2 is a modified epoxy resin material. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com