Connecting-rod type part large end lateral clamping device with linkage resetting function

A technology of lateral clamping and connecting rods, which is applied in the direction of grinding drive devices, grinding machine parts, manufacturing tools, etc., can solve problems such as complex structures and complex operations, improve efficiency, avoid honing failure, and achieve remarkable results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

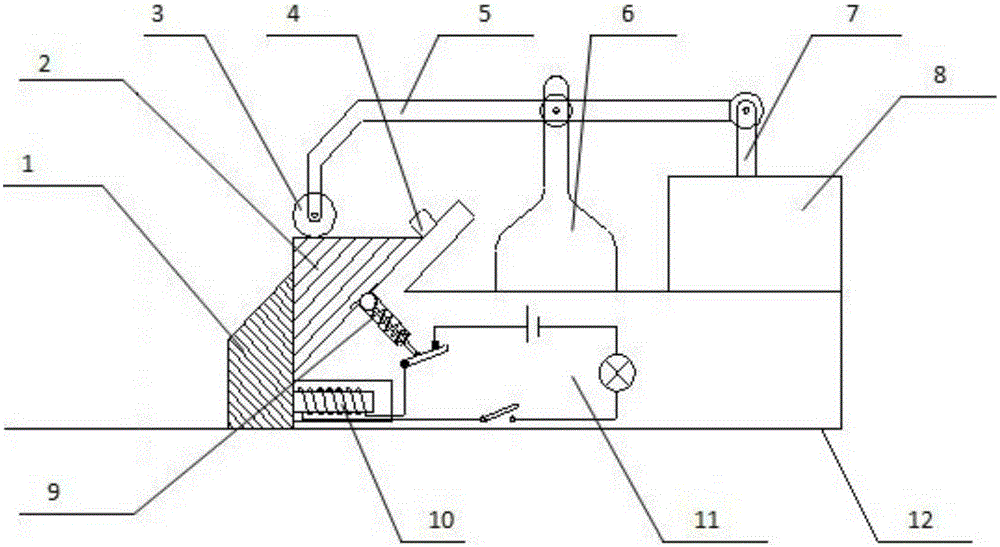

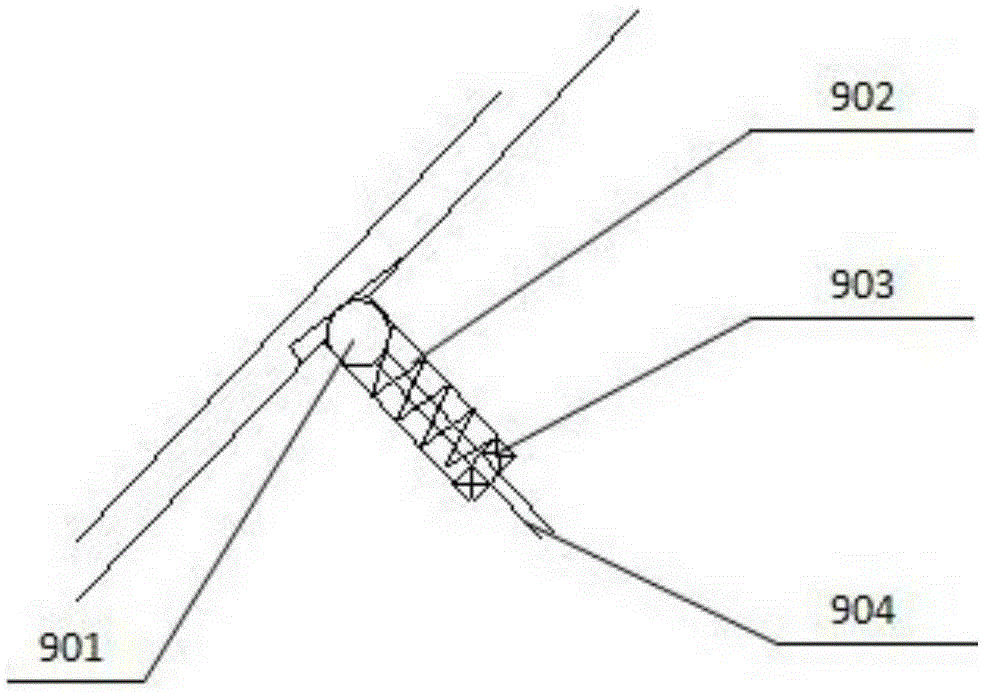

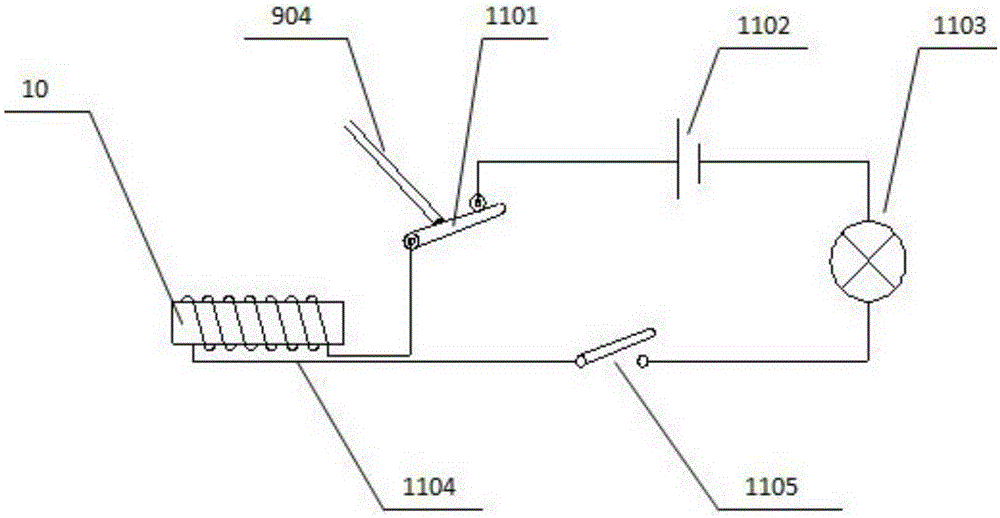

[0032] Such as figure 1 As shown, a large head side clamping device for connecting rod parts with a linkage reset function includes a power drive mechanism 8, a metal positioning member 1, a base 12, a pressing block 2, a movable switch mechanism, an electromagnetic suction mechanism and a force transmission mechanism. mechanism, the base 12 is provided with a vertical contact surface and an inclined contact surface, the vertical contact surface is provided with a first through hole and can touch the metal positioning member 1, the inclined contact surface is provided with a second th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com