Method and system for preparing nickel carbonyl powder through nickel-iron alloy

A technology of nickel-iron alloy and nickel carbonyl powder, which is applied in the field of metallurgy and can solve the problems of unfavorable nickel carbonyl synthesis and low nickel reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

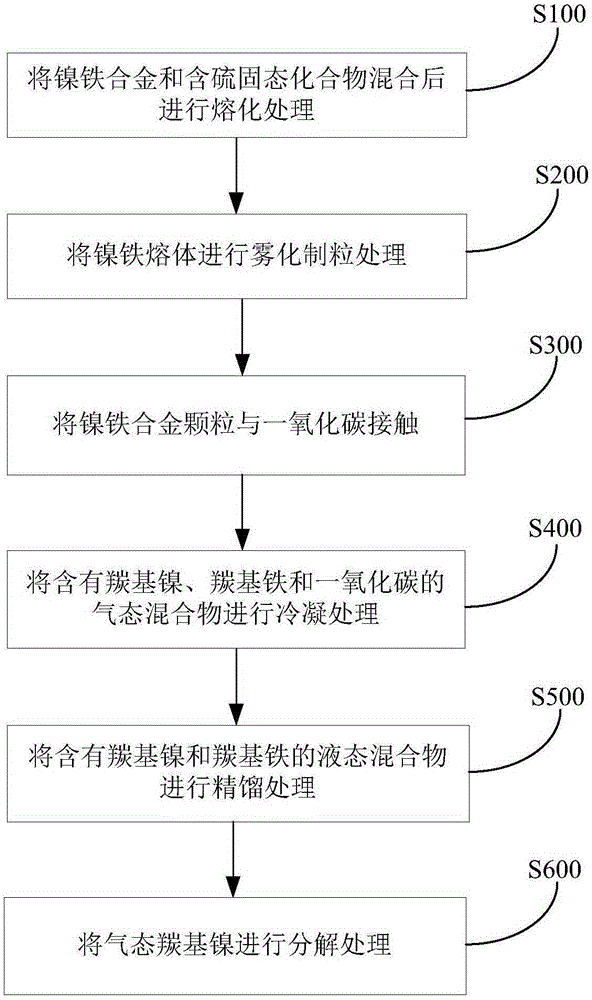

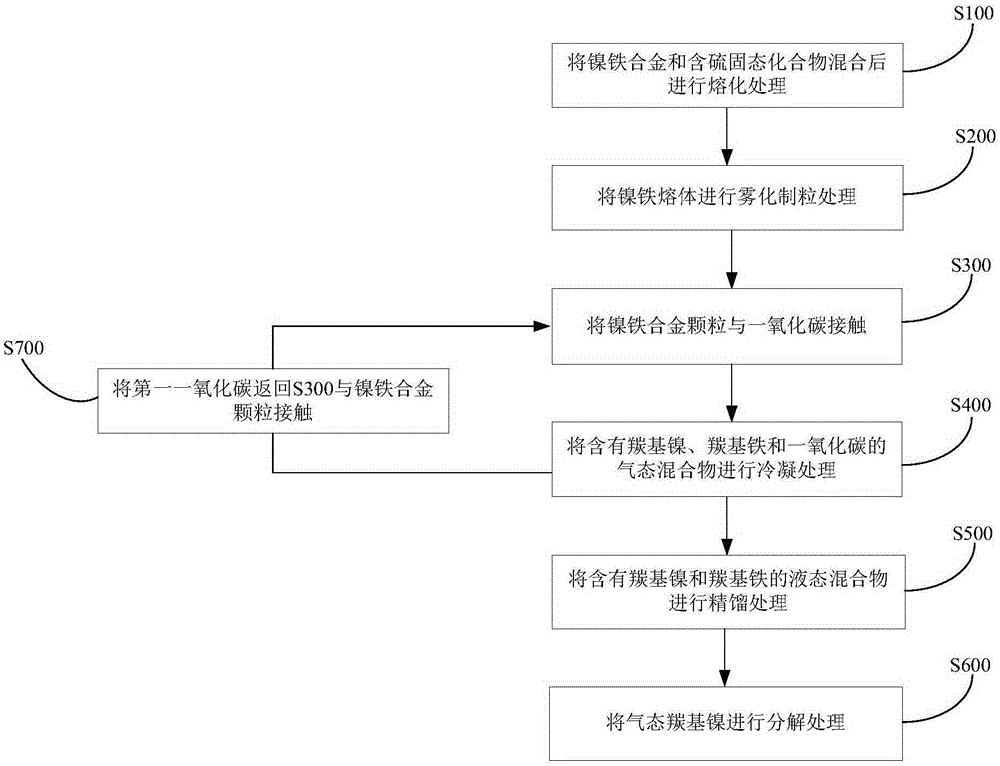

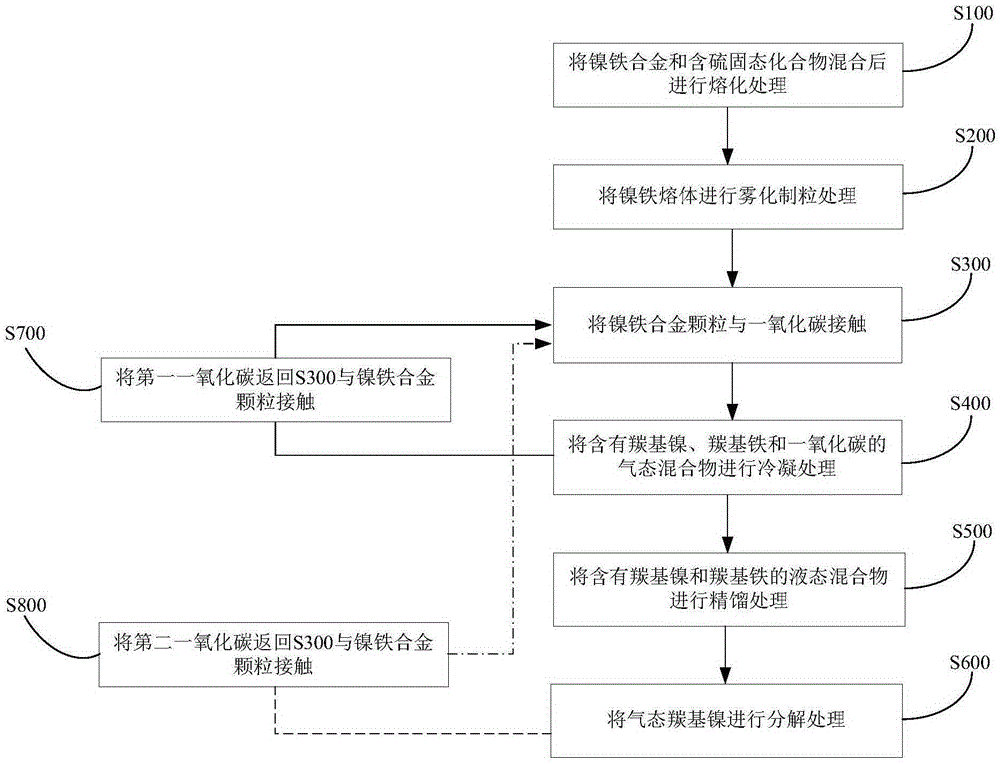

Method used

Image

Examples

Embodiment 1

[0099] Get the nickel-iron alloy of table 1 composition and carry out melting treatment after mixing iron sulfur, obtain nickel-iron melt (sulfur content is 0.5wt% in the nickel-iron melt), then gained nickel-iron melt is carried out atomization granulation treatment, obtains Nickel-iron alloy particles with an average particle size of 0.2 mm, and then contact the nickel-iron alloy particles with CO countercurrent to undergo a carbonylation reaction to generate a gaseous mixture containing nickel carbonyl, iron carbonyl and carbon monoxide. The carbonylation conditions are: pressure 7.5MPa, temperature 185 ° C, time 35h, the CO gas concentration is 90.5%, and then the gaseous mixture containing nickel carbonyl, carbonyl iron and carbon monoxide is sent to the condenser for condensation treatment to obtain a liquid mixture containing nickel carbonyl and carbonyl iron and carbon monoxide, and the carbon monoxide is returned to the oxo for continued use , and the obtained liquid m...

Embodiment 2

[0101] Get the nickel-iron alloy of table 1 composition and carry out melting treatment after mixing iron sulfur, obtain nickel-iron melt (sulfur content is 1.5wt% in the nickel-iron melt), then gained nickel-iron melt is carried out atomization granulation treatment, obtains Nickel-iron alloy particles with an average particle size of 0.5 mm, and then contact the nickel-iron alloy particles with CO countercurrent to undergo a carbonylation reaction to generate a gaseous mixture containing nickel carbonyl, iron carbonyl and carbon monoxide. The carbonylation conditions are: pressure 12.5MPa, temperature 135 ° C, time 46h, the CO gas concentration is 92%, and then the gaseous mixture containing nickel carbonyl, iron carbonyl and carbon monoxide is sent to the condenser for condensation treatment to obtain a liquid mixture containing nickel carbonyl and iron carbonyl and carbon monoxide, and the resulting carbon monoxide is returned to the oxo synthesis device to continue use, an...

Embodiment 3

[0103] Get the nickel-iron alloy of table 1 composition and carry out melting treatment after mixing sulfur iron, obtain nickel-iron melt (sulfur content is 3wt% in the nickel-iron melt), then gained nickel-iron melt is carried out atomization granulation process, obtains average Nickel-iron alloy particles with a particle size of 0.35 mm, and then contact the nickel-iron alloy particles with CO countercurrent to undergo a carbonylation reaction to generate a gaseous mixture containing nickel carbonyl, iron carbonyl and carbon monoxide. The carbonylation conditions are: pressure 15MPa, temperature 155 ° C, time 29h, The CO gas concentration is 90%, and then the gaseous mixture containing nickel carbonyl, iron carbonyl and carbon monoxide is sent to the condenser for condensation treatment to obtain a liquid mixture containing nickel carbonyl and iron carbonyl and carbon monoxide, and the carbon monoxide is returned to the oxo for continued use, while The resulting liquid mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com