Molten metal scum quick removal device and operation method

A cleaning device and liquid metal technology, applied in the field of metallurgy, can solve the problems of large metal loss, low slag removal rate, low work efficiency, etc., and achieve the effects of low risk, simple operation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

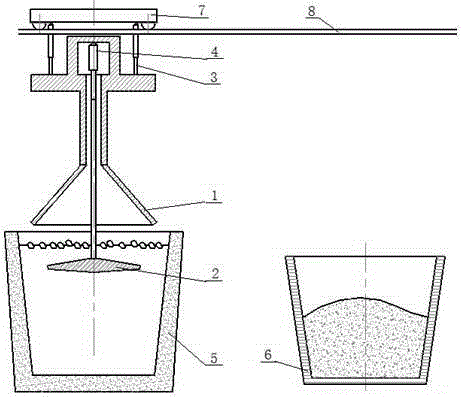

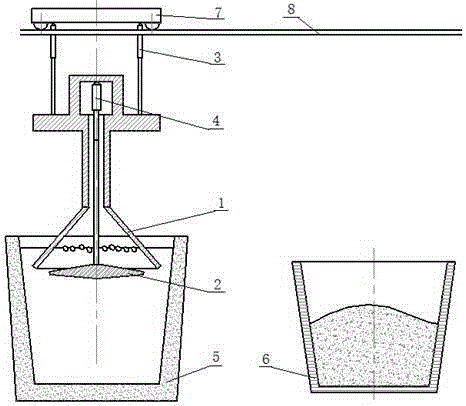

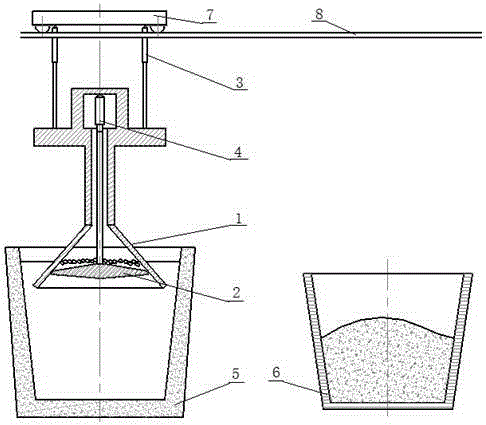

[0019] A liquid metal scum rapid cleaning device, the structure of which includes a conical slag collector (1), a conical slag stopper (2), a slag collector lifting device (3), a slag stopper lifting device (4), a moving Vehicle loading (7), transfer track (8); the conical slag collector (1) is rigidly connected to the bottom of the slag collector lifting device (4), and the conical slag collector (1) is connected to the slag collector lifting device (3), the slag accumulator lifting device (3) is fixed on the bottom of the transfer vehicle (7); the conical slag stopper (2) is connected to the bottom of the slag stopper lifting device (4), and the slag stopper lifting device ( 4) Fix on the lifting device (3) of the slag accumulator, the lifting device (3) of the slag accumulator is rooted on the transfer vehicle (7), and the transfer vehicle (7) is on the transfer track (8).

[0020] The conical slag accumulator (1) is an open space structure whose inner surface facing downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com