Three-segment vertical type magnesium alloy cast-rolling flow distributing device

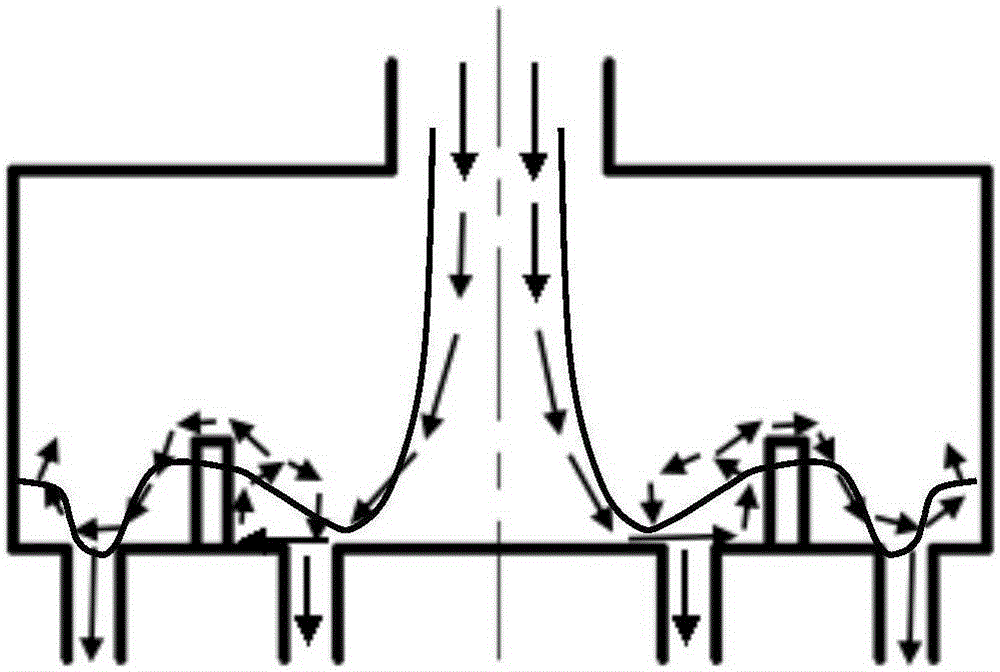

A magnesium alloy, casting and rolling technology, which is applied in the field of three-stage vertical magnesium alloy casting and rolling flow distribution devices, can solve the problems of uneven cast-rolled plate shape, uneven distribution of thickness and width, and oxidation of the edge of the cast-rolled magnesium plate. , to achieve the effect of uniform flow distribution, uniform flow distribution, and impact mitigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

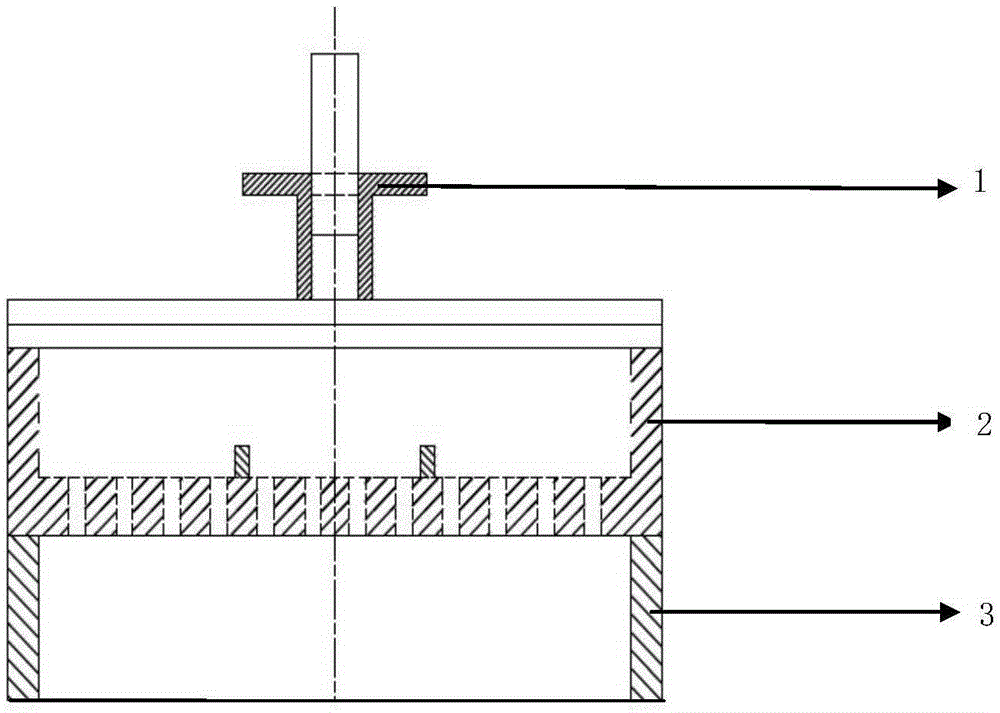

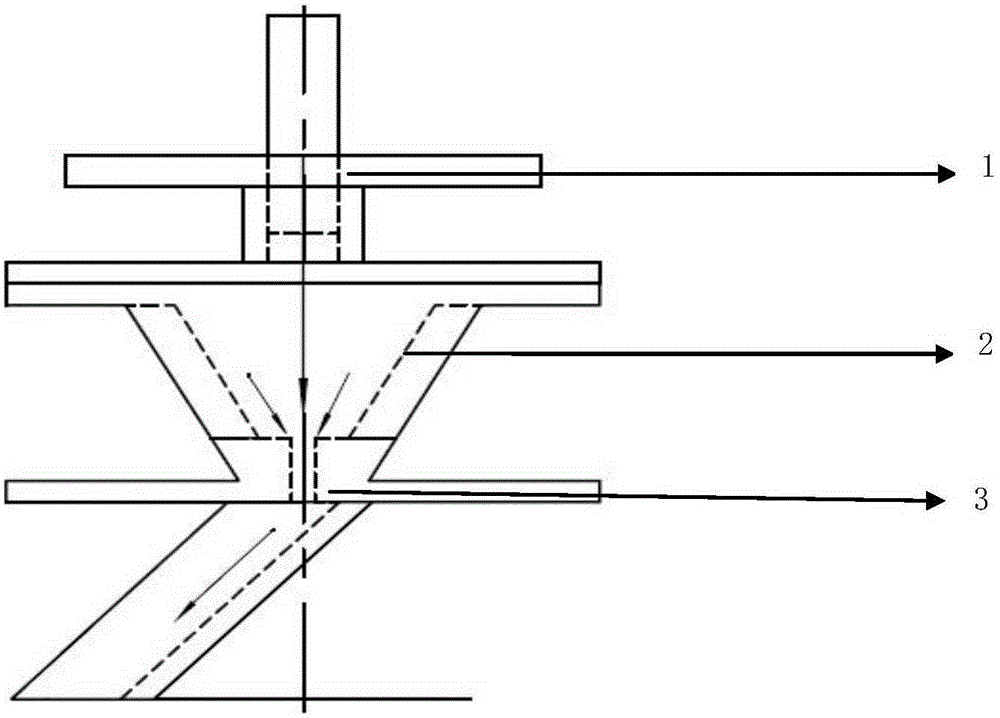

[0013] like figure 1 and figure 2 As shown, a three-stage vertical magnesium alloy casting and rolling flow distribution device is composed of a straight pipe flow diverter 1, a porous diffuser flow distributor 2 and a sloping plate buffer 3. The straight pipe flow diverter 1 A cylindrical channel is adopted, and the multi-hole diffuser 2 is provided with a plurality of diversion holes of different sizes at different intervals along the width direction of the casting roll, or a dam is set at the bottom of the casting roll, or a dam is set at the bottom to evenly distribute the flow of each hole The bottom surface is inclined, the straight pipe diverter 1 is connected to the bottom of the melting furnace, the porous diffuser 2 is connected to the bottom of the straight pipe diverter 1, and the inclined plate buffer 3 is connected to the bottom of the porous diffuser 2. The diversion hole diameter of the porous diffuser 2 is Φ5-Φ30mm, and the hole spacing is 10-200mm; the heig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com