Polymer homopore membrane preparation method

A polymer and porous membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effect of simple implementation steps, wide range of applicable monomers, and loose polymerization conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

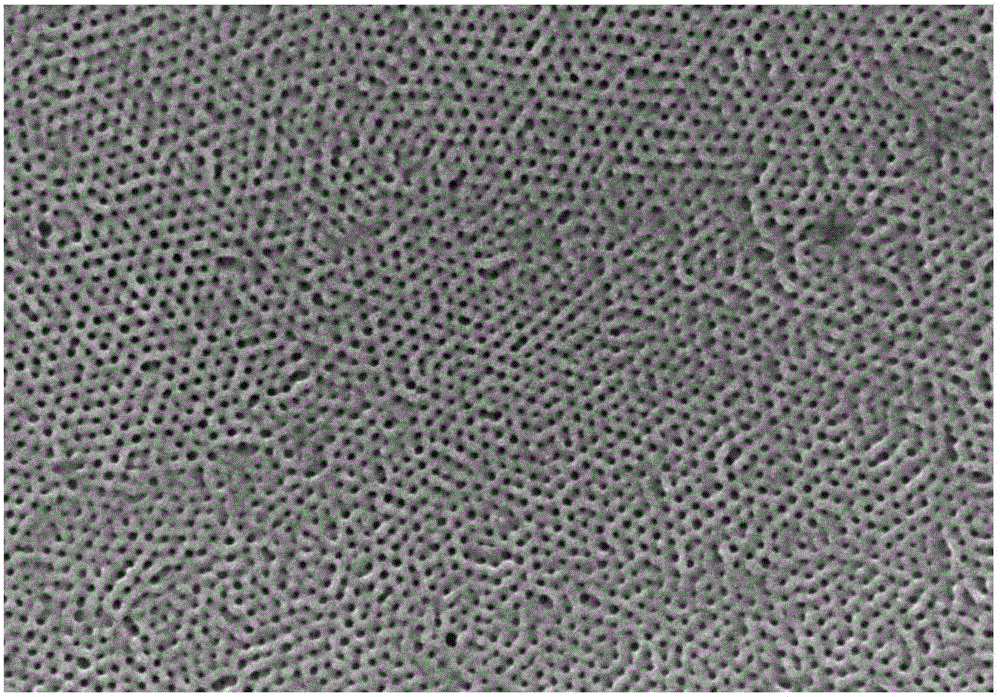

[0032] A method for preparing a polymer homoporous membrane, the steps are as follows:

[0033] (1) Dissolve polystyrene-block-poly(4-vinylpyridine) with a number average molecular weight of 50,000 g / mol and a molecular weight distribution index (PDI) of 1.45 into 20 wt% of 1,4-dioxane ring, 30wt% tetrahydrofuran and 50wt% N,N-dimethylformamide form a mixed solvent in which a casting solution is formed, wherein the total concentration of the block copolymer in the casting solution is 21wt%, and in the block copolymer The mass contents of polystyrene and poly(4-vinylpyridine) are 75wt%, 25wt% respectively;

[0034] (2) Standing and aging the above casting solution at room temperature of 25° C. for 12 hours;

[0035] (3) The aged casting solution is salivated into a film with a thickness of 150 μm by a scraper;

[0036] (4) the above-mentioned film is 20% relative humidity, and the temperature is 50 ℃ of air stays 30s;

[0037] (5) Immerse the flat membrane in high-purity wat...

Embodiment 2

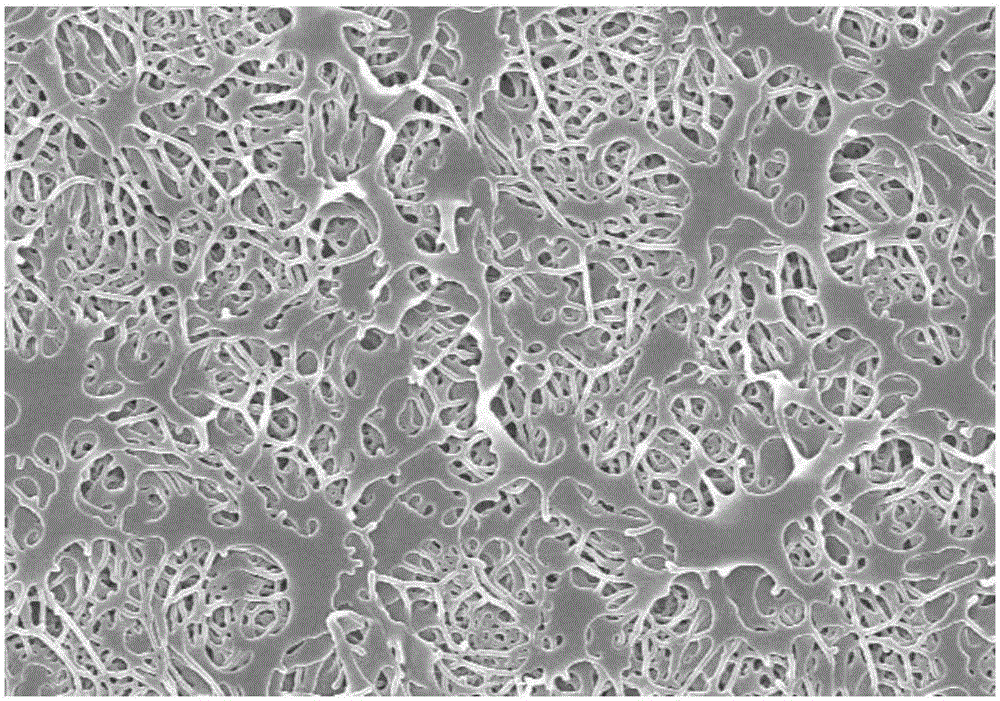

[0041] A method for preparing a polymer homoporous membrane, the steps are as follows:

[0042] (1) Dissolve polystyrene-block-poly(4-vinylpyridine) with a number average molecular weight of 500,000 g / mol and a molecular weight distribution index (PDI) of 1.2 into 10 wt% of 1,4-dioxane ring, 60wt% tetrahydrofuran and 30wt% N, N-dimethylformamide form a mixed solvent in which a casting solution is formed, wherein the total concentration of the block copolymer in the casting solution is 31wt%, and in the block copolymer The mass contents of polystyrene and poly(4-vinylpyridine) are 65wt%, 35wt% respectively;

[0043] (2) Standing and aging the above casting solution at room temperature of 25° C. for 2 hours;

[0044] (3) The aged casting solution is salivated into a film with a thickness of 150 μm by a scraper;

[0045] (4) The above-mentioned film is left in the air with a relative humidity of 70% and a temperature of 35° C. for 1 second;

[0046] (5) Immerse the flat membra...

Embodiment 3

[0049] A method for preparing a polymer homoporous membrane, the steps are as follows:

[0050](1) The number-average molecular weight is 430,000g / mol, and the polystyrene-block-poly(4-vinylpyridine)-block-poly(methyl acrylate) whose molecular weight distribution index (PDI) is 1.19 is dissolved to 1wt% 1,4-dioxane, 49wt% tetrahydrofuran and 50wt% N,N-dimethylformamide form a mixed solvent in which a casting solution is formed, wherein the total concentration of the block copolymer in the casting solution is 26 wt%, and the mass fractions of polystyrene, poly(4-vinylpyridine) and polymethyl acrylate in the block copolymer are 65 wt%, 15 wt% and 20 wt%.

[0051] (2) Standing and aging the above casting solution at room temperature of 25° C. for 12 hours;

[0052] (3) The aged casting solution is salivated into a film with a thickness of 150 μm by a scraper;

[0053] (4) Stay 200s in the air with a relative humidity of 5% and a temperature of 75° C.;

[0054] (5) Immerse the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com