Novel fire extinguisher

A fire extinguisher and a new type of technology, applied in fire rescue and other directions, can solve problems such as personal injury, injury to users, and large momentum, and achieve the effects of reducing injury, ensuring explosion venting safety, and preventing explosion and deflagration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

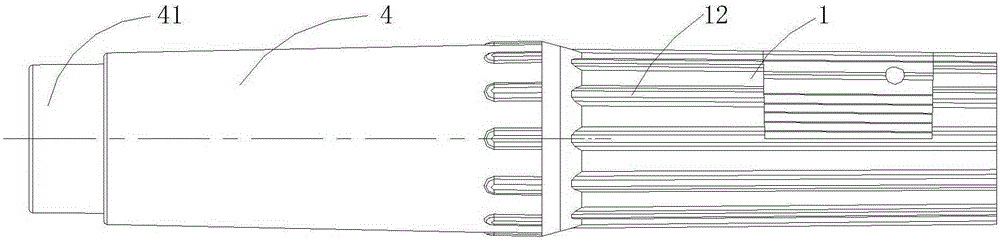

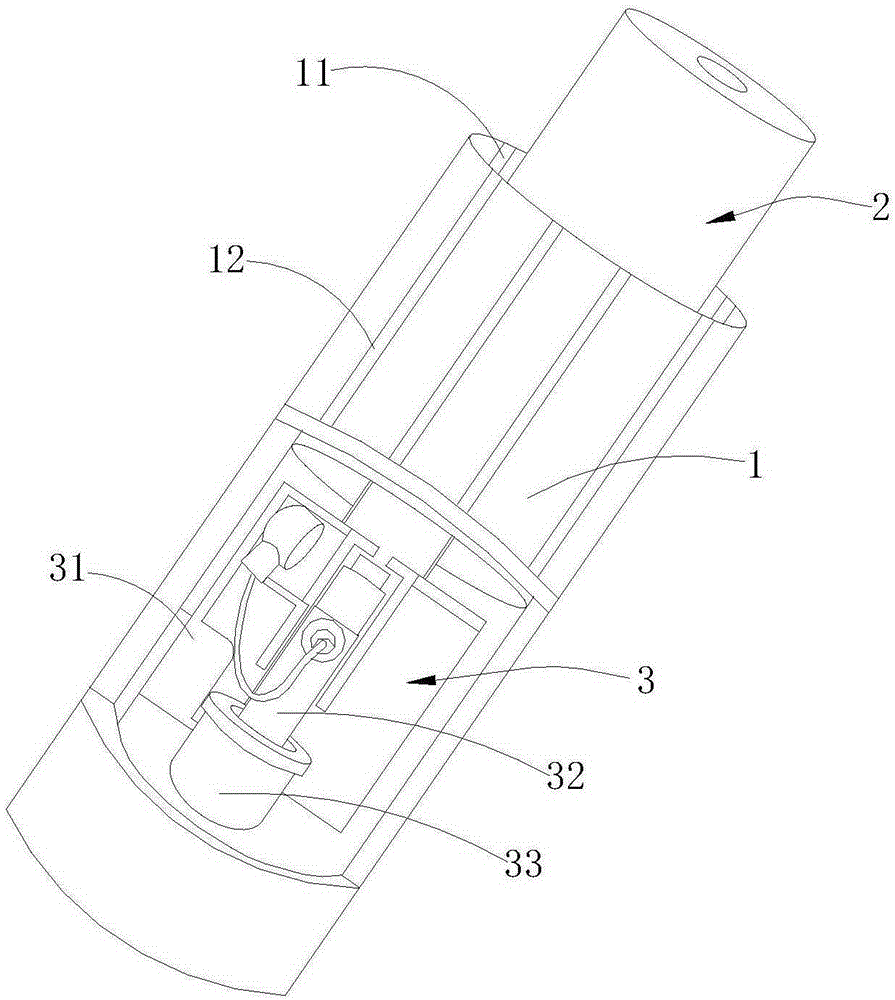

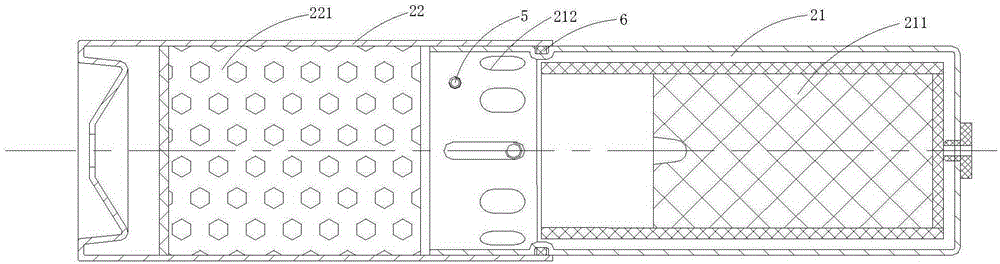

[0020] see figure 1 , figure 2 , image 3 As shown, a new type of fire extinguisher includes an outer shell 1 and an inner cylinder 2 inserted in the shell cavity of the outer shell 1 . The inner cylinder 2 includes a first inner cylinder 21 which stores a fire extinguishing agent 211 and is inserted in the cavity of the outer shell 1 along the front-rear direction, and a first inner cylinder 21 which stores a coolant and is slidably sleeved on the outer wall of the front end of the first inner cylinder 21 . 221 of the second inner cylinder 22, the inner cylinder 2 also includes an explosion vent 212 provided on the side wall of the first inner cylinder 21, and an explosion vent 212 provided on the side wall of the second inner cylinder 22. On or away from the shielding part of the explosion vent 212, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com