LED lamp filament illuminating strip and preparation method therefor

A technology of LED filaments and light strips, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of affecting light transmission, uneven light mixing, and hindering heat dissipation, so as to improve the uniformity of light output and reduce Package cost, effect of improving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

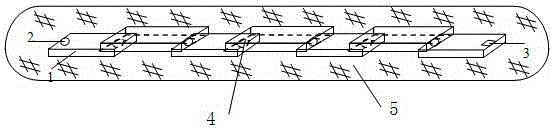

[0027] The LED filament light emitting strip of the present invention is such as image 3 As shown, two rows of LED chips are included, and the lower row of LED chips is arranged on the upper row of LED chips. The LED chips 1 in the lower row are arranged at intervals, and the LED chips in the upper row are respectively overlapped between two adjacent LED chips 1 in the lower row. The LED chips in the lower row are opposite to the light emitting surface of the LED chips in the upper row. The positive electrode and the negative electrode of the LED chip in the upper row are respectively welded to the negative electrode and the positive electrode of the two adjacent LED chips 1 in the lower row to form a chip bar, and the fluorescent glue 5 is coated on the chip bar.

[0028] The preparation steps of the above LED filament light-emitting strip are as follows:

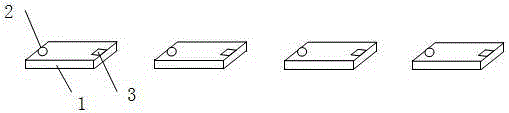

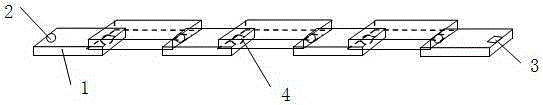

[0029] (1) Such as figure 1 As shown, the lower row of LED chips are arranged, and the LED chips in the lower row are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com