Circuit breaker electrical contact support member and preparation method thereof

A technology for supporting parts and circuit breakers, applied in circuit breaker parts, circuit breaker contacts, electrical components, etc., can solve the problems of difficult control of surface contact resistivity, Fe metal is easily oxidized, and bonding strength cannot be obtained. Reduce the degree of ablation, achieve convenience, and improve competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

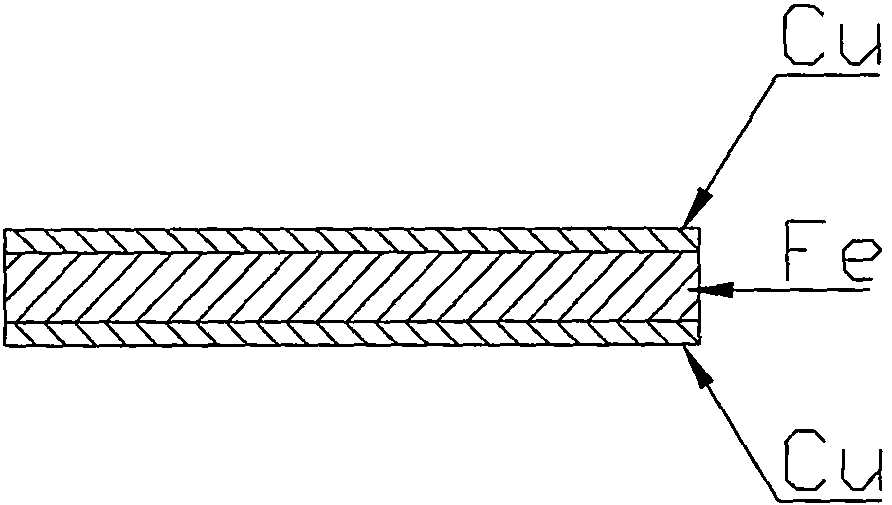

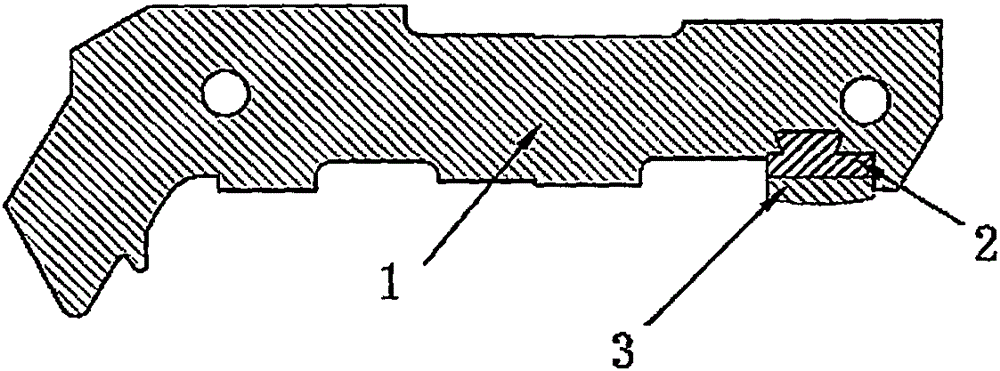

[0050] to prepare as figure 2 The shape shown in the support is taken as an example, wherein the groove is a dovetail groove, and the contact is made of AgW50; the insert 2 is made of pure Cu, and its shape is dovetail. A method for preparing a support for an electrical contact of a circuit breaker, comprising the following steps:

[0051] The first step: clean the pure Fe material tape and the pure Cu material tape with organic solvent and acid solution respectively, clean the pure Cu material tape and the pure Fe material tape, and clean the pure Cu tape and the pure Fe tape Solid-phase rolling composite at room temperature to prepare Cu / Fe / Cu structured strips, wherein: after rolling, the width of the strip is 150mm, the thickness is 20mm, and the thickness of the Cu layer on each side accounts for 20% of the thickness of the entire strip. The two Cu layers of the Cu / Fe / Cu strip are located on both sides and the Fe layer is in the middle.

[0052] The second step: heat-t...

Embodiment 2

[0061] to prepare as image 3 The shape support shown is an example, wherein the groove is an L-shaped groove, and the contact is made of AgWC material; the insert 2 is made of AgNi, and the shape is an L-shaped insert; the preparation method of the circuit breaker electrical contact support includes the following step:

[0062] The first step: Surface treatment of Cu strips and Fe strips, impregnation of Cu strips as soluble anodes, impregnation of Fe strips as cathodes, and electroplating of these anodes and cathodes to prepare Cu / Fe / Cu The material strip of the structure, wherein: the Fe material width is 80mm, the thickness is 3mm, the Cu layer thickness percentage of each side after electroplating is respectively 5%, and the electroplating bath is a pyrophosphate copper plating bath.

[0063] Step 2: Carry out heat treatment to Cu / Fe / Cu strip, wherein: the temperature of heat treatment is 300 degrees, the time is 2 hours, the atmosphere is N 2 .

[0064] Step 3: rollin...

Embodiment 3

[0072] to prepare as Figure 4 Taking the shape support as an example, the groove is a trapezoidal groove, and the contact is made of AgWC22C3; the insert 2 is made of CuNi, and its shape is trapezoidal. A method for preparing a support for an electrical contact of a circuit breaker, comprising the following steps:

[0073] The first step: bend the Cu strip into a U shape, wherein the width of the bent strip is the same as that of the Fe strip, and the height of the U-shaped gap is equal to or slightly smaller than the thickness of the Fe strip, and the Fe strip is inserted into the In the U-shaped Cu material strip, carry out cold rolling and compounding at room temperature to prepare a material strip with a Cu / Fe / Cu structure. After rolling, the material bandwidth is 50mm, the thickness of the material strip is 10mm, and the thickness percentage of each Cu layer is 10. %. like figure 1 shown.

[0074] The second step: heat-treat the Cu / Fe / Cu strip, wherein: the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com