Completion parameters and productivity optimization method of two-phase flow perforation in high temperature and high pressure oil and gas vertical wells

A high-temperature, high-pressure, optimization method technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of not meeting the production accuracy requirements and being unusable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0160] The invention aims at proposing a high-temperature and high-pressure oil-gas vertical well two-phase flow perforation completion parameter and productivity optimization method to accurately predict the perforation parameters so as to improve the productivity ratio of the oil-gas well.

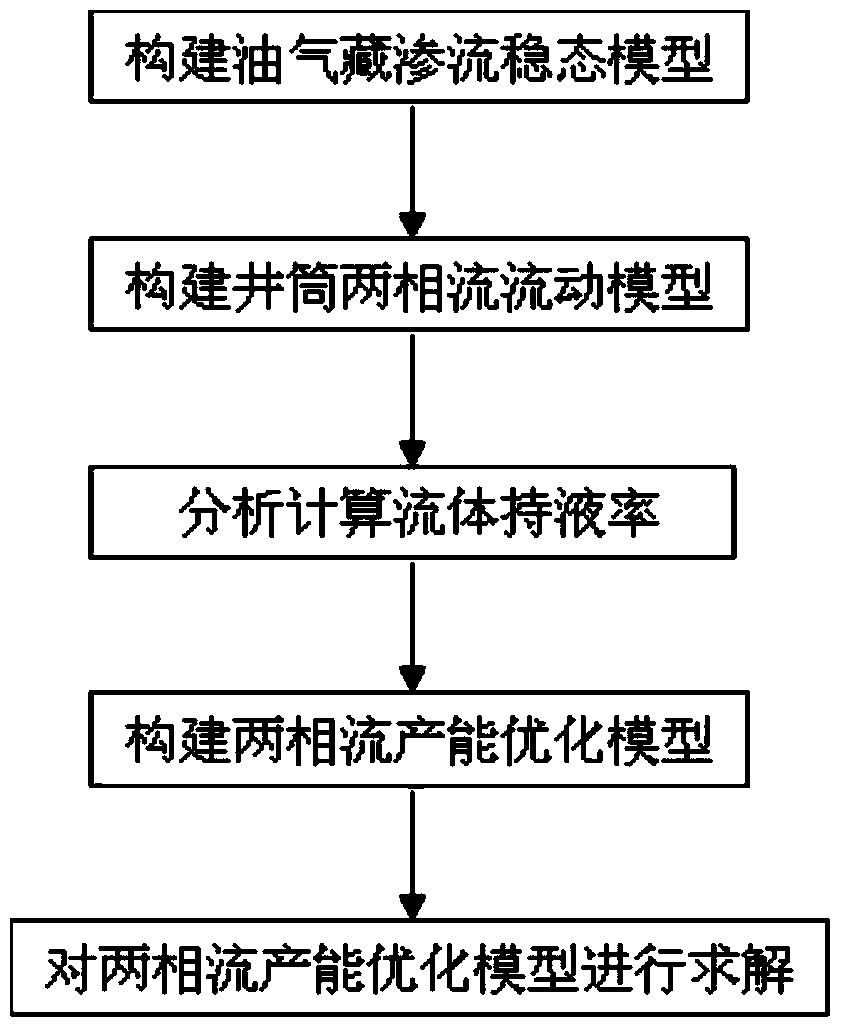

[0161] Such as figure 1 As shown, the method includes: 1. Constructing a seepage steady-state model of oil and gas reservoirs; 2. Constructing a wellbore two-phase flow flow model; 3. Analyzing and calculating fluid holdup; 4. Constructing a two-phase flow productivity optimization model; The optimization model of phase flow capacity is solved.

[0162] The implementation mode of each step is described in detail below:

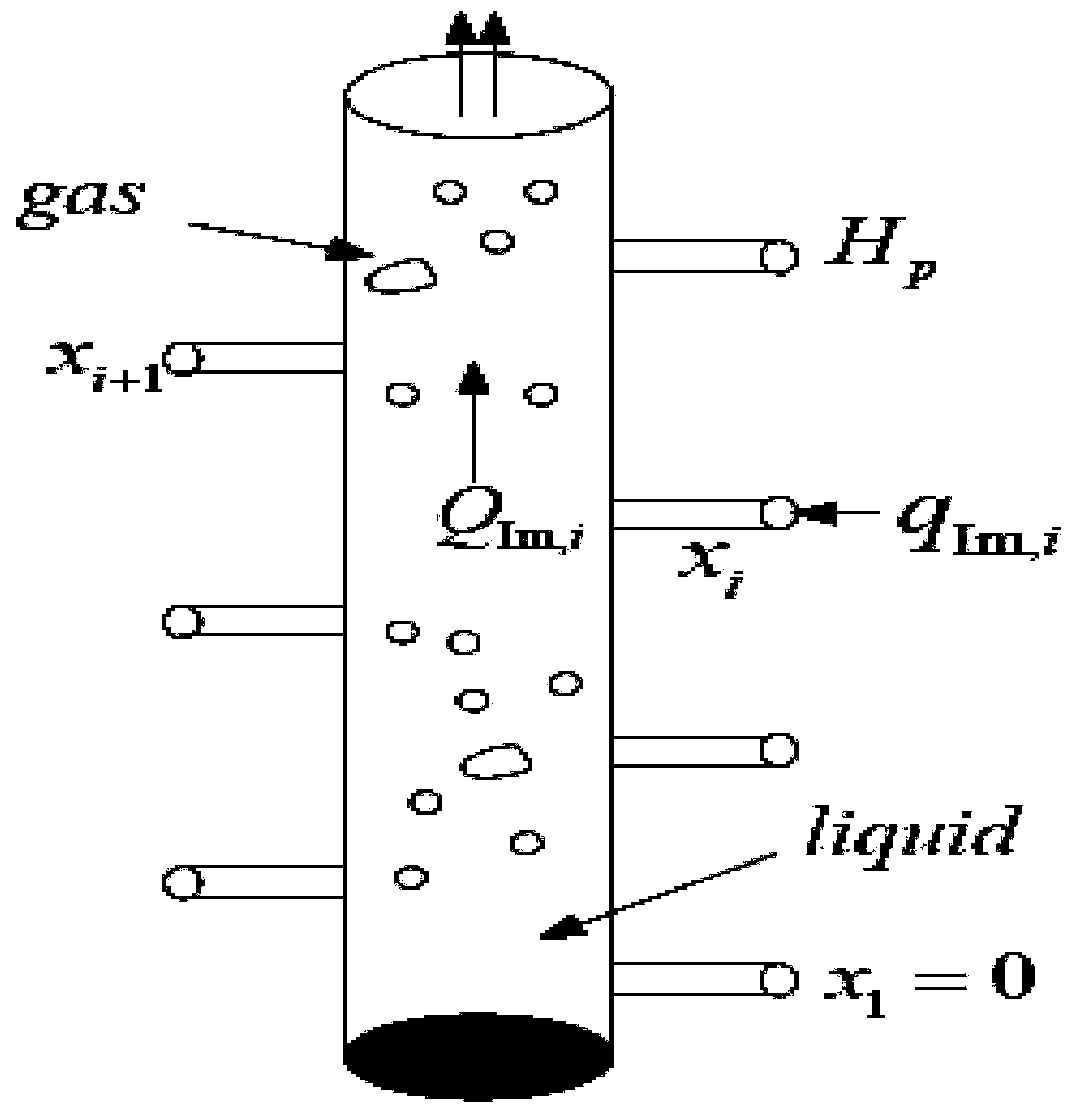

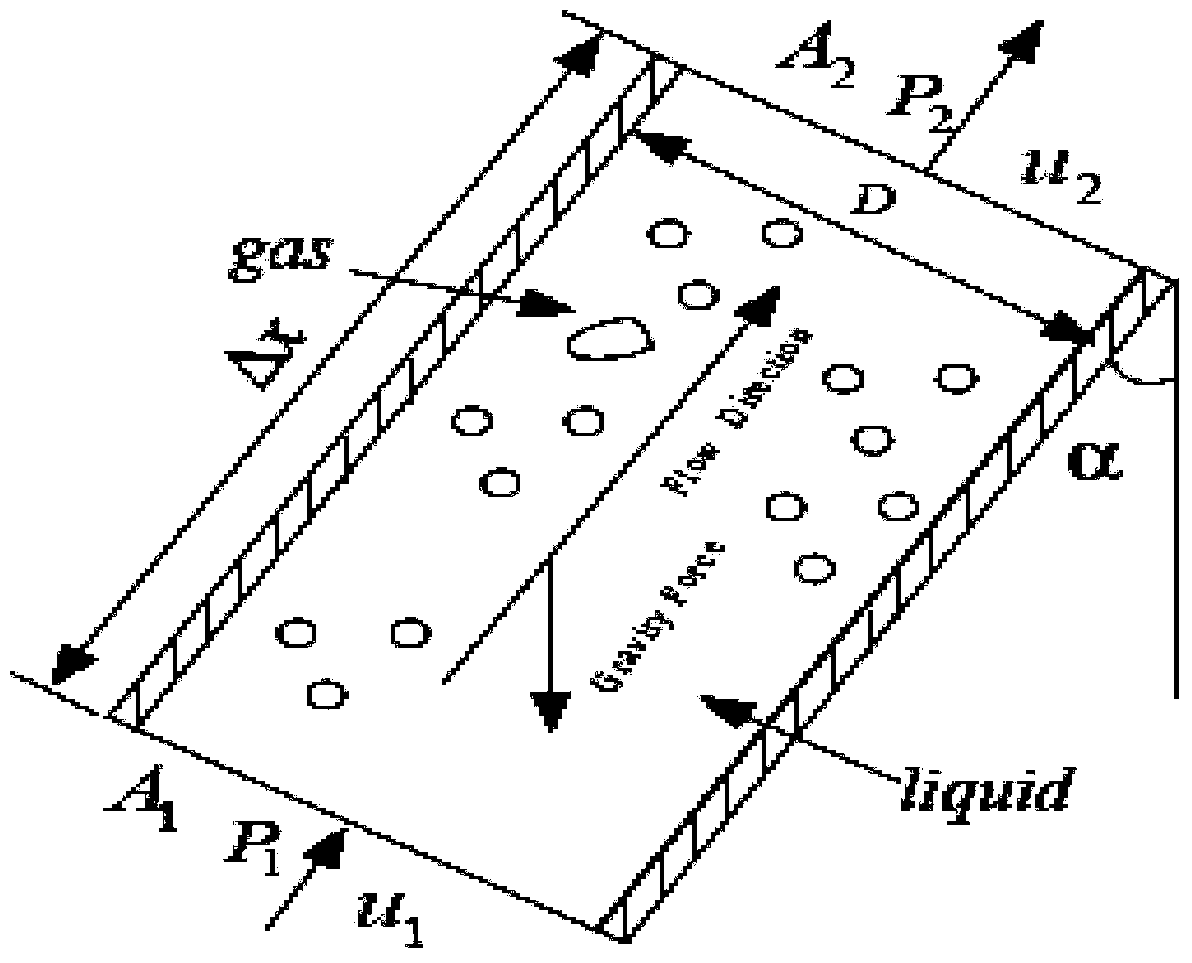

[0163] The pressure drop in the wellbore is an important parameter in gas well design, which is of great significance to the optimization design of gas well parameters, production stability and increase, and well test design. The pressure drop relationship of gas-liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com