A new type of nano-carbon crystal electric strip heating floor and its preparation method

A nano-carbon crystal and floor technology, which is applied in heating methods, electric heating systems, household heating, etc., can solve the problems of less research on electric heating floors, achieve high electric heating conversion rate, fast heating rate, and improve heating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

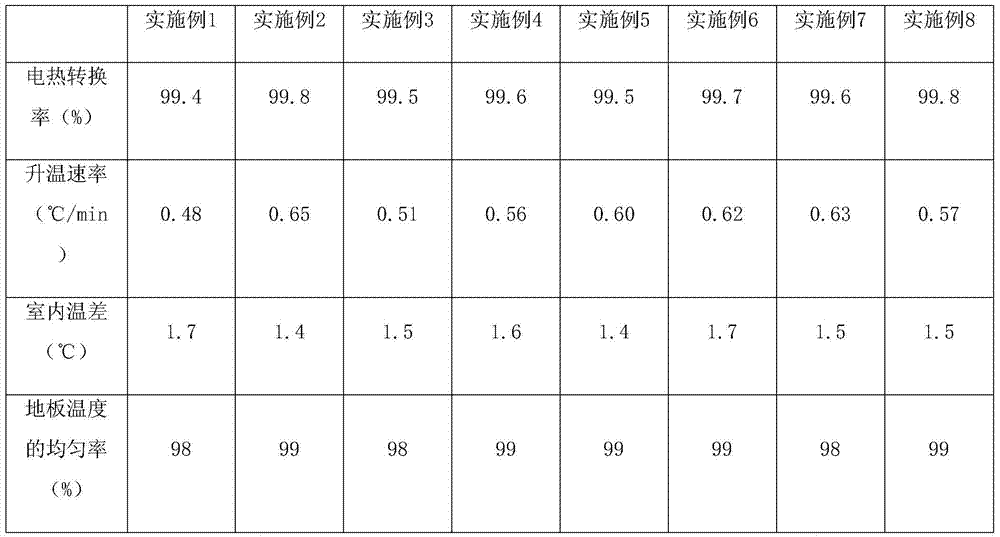

Examples

Embodiment 1

[0029] (1) Place the nanoscale PAN-based short carbon fibers with a diameter of 200-500nm in an alkaline solution that is dissolved in a pH value of 8.5, separate after ultrasonic treatment for 30min, place in 1mol / L ammonium bicarbonate solute, and Under the condition that the electric quantity of oxidation is 250C / g, anodize the surface for 15 minutes, take it out, clean it with ethanol, dry it, place it in a high-energy ball mill and pulverize it, and obtain a modified nano-carbon crystal with a length less than 5 μm.

[0030] (2) In parts by weight, 5 parts of diffusing agents are added in the modified nano-carbon crystals prepared by 20 parts of step (1) and 10 parts of graphite powder, mixed and ground, and 65 parts of plant puree are added, The homogenizer stirs evenly, and after heating and pressing, a planar modified nano-carbon crystal heating material is obtained.

[0031] (3) The two ends of the planar modified nano-carbon crystal heating material prepared in step ...

Embodiment 2

[0034] (1) Place the nanoscale PAN-based short carbon fibers with a diameter of 200-500nm in an alkaline solution that is dissolved in a pH value of 9, separate after ultrasonic treatment for 25min, place in 3mol / L ammonium bicarbonate solute, and Under the condition of oxidation electricity of 500C / g, the anodized surface was treated for 30 minutes, taken out, cleaned with ethanol, dried, placed in a high-energy ball mill and pulverized to obtain modified nano-carbon crystals with a length less than 5 μm.

[0035] (2) In parts by weight, add 15 parts of diffusing agent, surfactant and bactericide in the modified nano-carbon crystal prepared by 40 parts of step (1) and 20 parts of graphite powder, mix and grind, and add 80 parts The plant puree of one part is stirred evenly by a homogenizer, heated and pressurized to obtain a planar modified nano-carbon crystal heating material.

[0036] (3) The two ends of the planar modified nano-carbon crystal heating material prepared in s...

Embodiment 3

[0039] (1) Place nanoscale PAN-based short carbon fibers with a diameter of 200-500nm in an alkaline solution that is dissolved in an alkaline solution with a pH value of 8.7, separate after ultrasonic treatment for 20min, and place in 1.5mol / L ammonium bicarbonate solute, Under the condition of oxidation electricity of 300C / g, anodize the surface for 20 minutes, take it out, clean it with ethanol, dry it, place it in a high-energy ball mill and pulverize it to obtain modified nano-carbon crystals with a length less than 5 μm.

[0040](2) In parts by weight, add 10 parts of diffusion agent and surfactant in the modified nano-carbon crystal prepared by 30 parts of step (1) and 15 parts of graphite powder, mix and grind, and add 70 parts of plant The original slurry is stirred evenly by a homogenizer, heated and pressurized to obtain a planar modified nano-carbon crystal heating material.

[0041] (3) The two ends of the planar modified nano-carbon crystal heating material prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com