Prestressed steel plate shear wall capable of separating tension field

A steel plate shear wall and separation tension technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of component damage, steel plate buckling, etc., and achieve a good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the drawings.

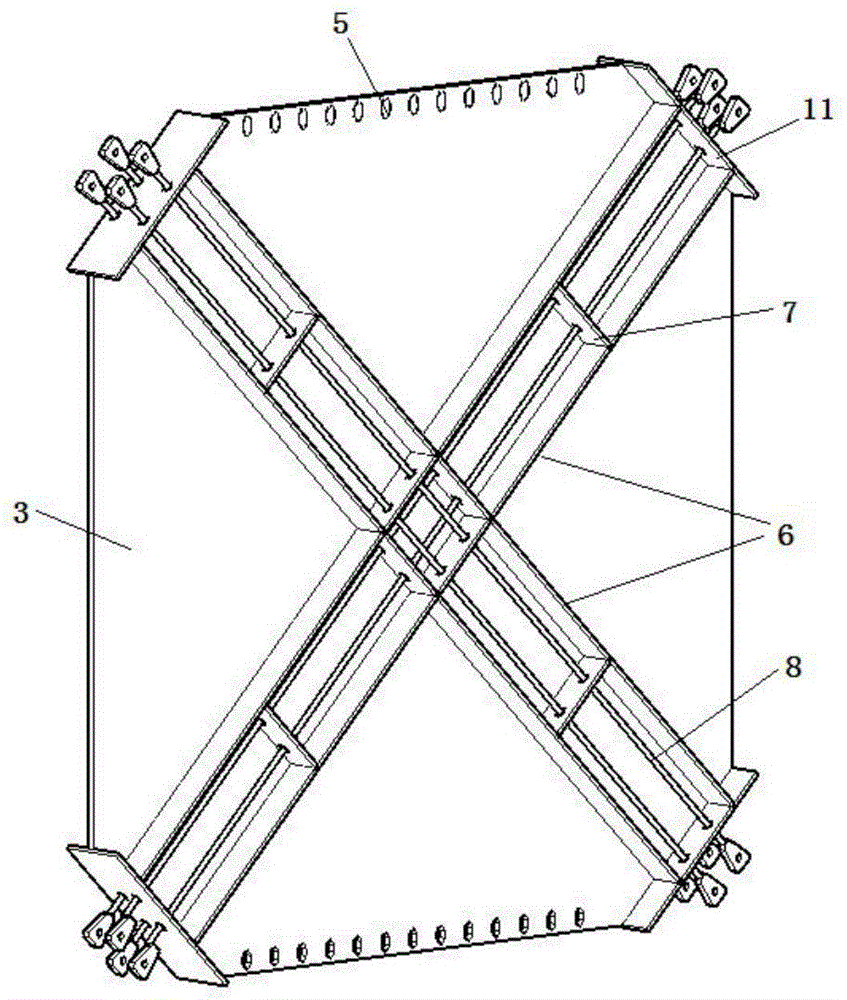

[0032] A prestressed steel plate shear wall with separable tension bands. The shear wall includes a prestressed steel plate wall, a steel frame and edge members.

[0033] Among them, the steel frame and edge members include steel beams (1), steel columns (2), horizontal edge connectors (4), high-strength bolts with long round holes (5), and corner connectors (9);

[0034] Prestressed steel plate walls include steel plate walls (3), prestressed cables (8), diagonal braces with holes (6), ribs with holes (7), and steel wall corner sealing plates (11);

[0035] The steel beam (1) and the steel column (2) are connected to form a conventional rectangular steel frame, and the four corner joints of the rectangular steel frame are welded with corner connectors (9). Wherein the corner connecting piece (9) is welded with an anchor (10) and a corner connecting piece sealing plate (12). The anchor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com