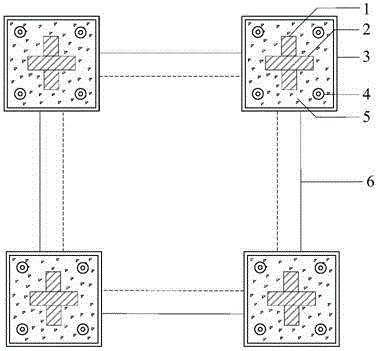

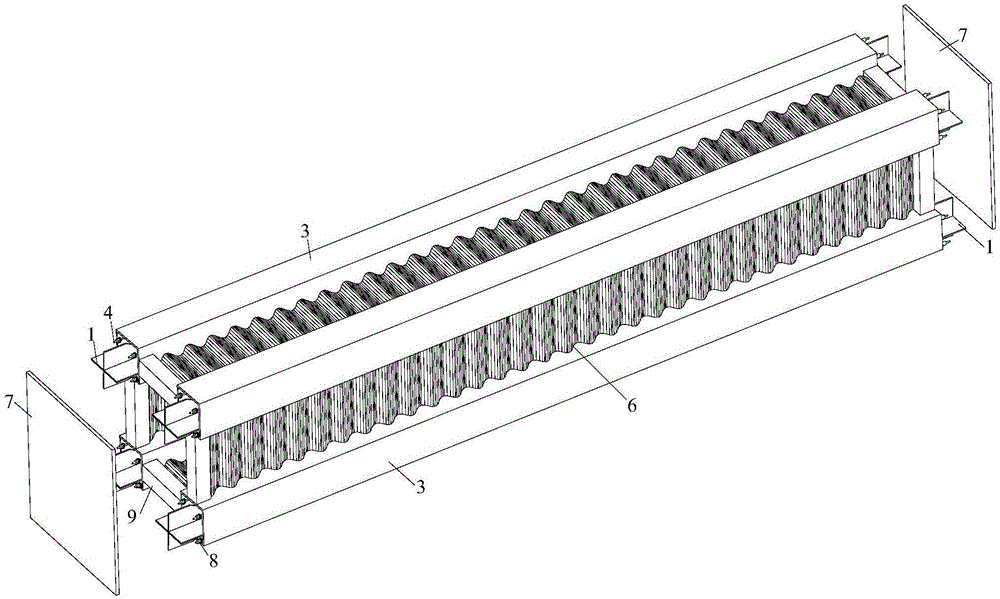

Four-limb pre-stressed anti-buckling member connected through wavy webs

A wavy web and anti-buckling technology, which is applied to building components, earthquake resistance, building construction, etc., can solve the problems of wasting materials and the advantages of cross-section expansion are not brought into play, and achieve the effect of large selection range and flexible application time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

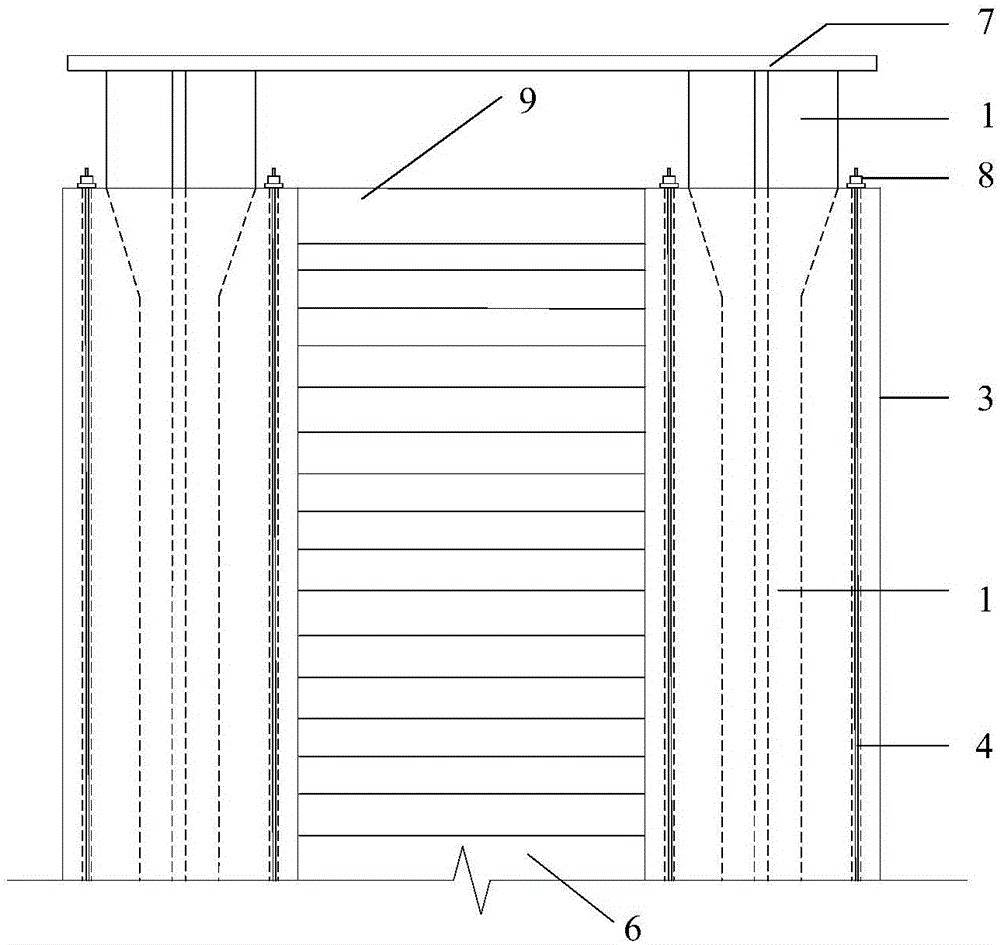

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is compared with the buckling-resistant members of steel pipe concrete restraints connected with corrugated webs but not provided with prestress, and the stress difference between the two is further analyzed.

[0016] Note that the inner core of a single anti-buckling support limb bears the axial pressure N, assuming that the four limbs bend in the same direction and have the same bending deflection, the extrusion force between the peripheral constraining members of each limb and the inner core follows a single-wave sinusoidal curve mode distribution, the mid-span extrusion force amplitude is q 0 , axial pressure N / 4 and q 0 Satisfy a linear relationship between them, that is, the distribution function of the extrusion force is q=q 0 sin(πx / L), where L is the length of the peripheral constraining member. The outer restraint members are in bending state under the action of extrusion force, and the mid-span bending moment is the largest, so the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com