Lactobacillus amylovorus for producing feruloyl esterase and application of lactobacillus amylovorus

A technology of Lactobacillus amylovora and ferulic acid esterase, which is applied in the biological field and can solve the problems of low yield of ferulic acid esterase and the inability to meet industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

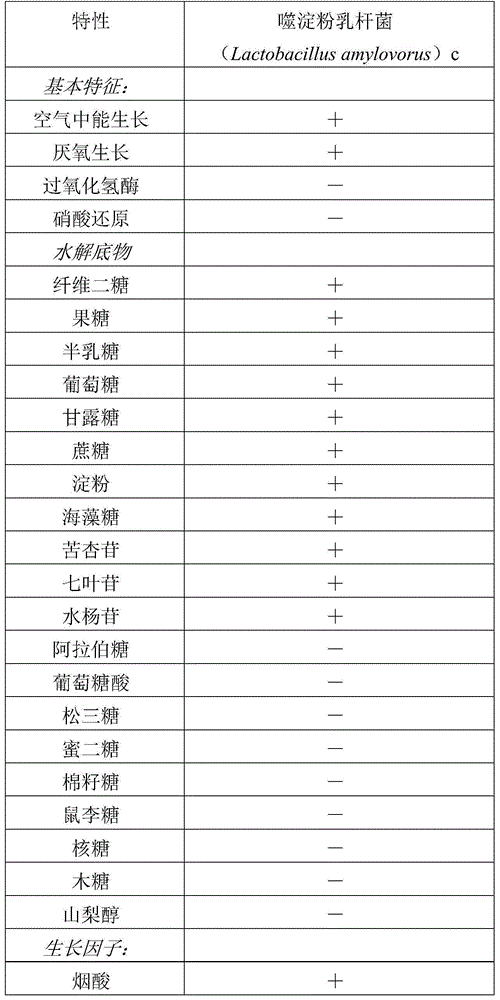

[0027] Example 1: Screening and identification of physiological and biochemical characteristics of Lactobacillus amylovorus c strain

[0028] The Shandong silage fermented corn feed sample was washed with sterile water and appropriately diluted, spread on the MRS medium agar plate, cultured at 37°C for 24 hours, picked white round colonies negative for catalase, and the microscopic examination was long Bacillus, repeatedly streaked to determine pure colonies, inoculated into MRS medium, microscopic observation of individual morphology and biochemical reaction measurement, and finally screened to obtain a strain of Lactobacillus amylovorus, which was named Lactobacillus amylovorus (Lactobacillus amylovorus) c.

[0029] The above-mentioned Lactobacillus amylovorus (Lactobacillus amylovorus) c is identified as a Gram-positive bacterium, facultatively anaerobic, non-spore-free, and immobile; the colonies are small and uniform, with neat edges, and milky white; the cells are long ro...

Embodiment 2

[0033] Embodiment 2: Experiment of amylase hydrolyzing starch produced by Lactobacillus amylovorus cCGMCCNo.11056

[0034] Lactobacillus amylovorus (Lactobacillus amylovorus) cCGMCCNo.11056 was transferred to a solid plate containing starch medium, and cultured at 37°C for 48 hours. Observe the clear circles produced by degrading the starch in the medium.

[0035] The formula of the above-mentioned starch-containing medium is: tryptone 10.0g, beef extract 10.0g, yeast powder 5g, soluble starch 10.0g, triammonium citrate 2.0g, magnesium sulfate 0.58g, manganese sulfate 0.25g, sodium acetate 3.12g, phosphoric acid Sodium hydrogen disodium 1.63g, potassium acetate 2.25g, Tween-801.0mL, distilled water 1000mL, agar 20.0g for solid, sterilized at 115°C for 30 minutes.

[0036] see results figure 1 .

[0037] Lactobacillus amylovorus (Lactobacillus amylovorus) cCGMCC No. 11056 was transferred to a starch-containing liquid medium, and cultured at 37° C. for 48 hours. Centrifuge a...

Embodiment 3

[0039] Example 3: Ferulic esterase produced by Lactobacillus amylovorus (Lactobacillus amylovorus) cCGMCCNo.11056 hydrolyzing ethyl ferulate

[0040] Lactobacillus amylovorus (Lactobacillus amylovorus) cCGMCCNo.11056 was inoculated into a solid medium containing ethyl ferulic acid, and cultured at 37°C for 72 hours. A clear circle due to the degradation of ethyl ferulate in the medium was observed.

[0041] Above-mentioned formula containing ethyl ferulate medium is: tryptone 10.0g, beef extract 10.0g, yeast powder 5g, DMSO solution 15mL of 10% (W / V) ethyl ferulate, triammonium citrate 2.0g, Magnesium sulfate 0.58g, manganese sulfate 0.25g, sodium acetate 3.12g, disodium hydrogen phosphate 1.63g, potassium acetate 2.25g, Tween-801.0mL, distilled water 1000mL, solids need to add agar 20.0g, sterilize at 115°C for 30 minutes.

[0042] see results figure 2 .

[0043] Transfer Lactobacillus amylovorus (Lactobacillus amylovorus) cCGMCCNo.11056 to a liquid medium containing ethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com