Water-based environment-friendly transfer paint with high smoothness on transfer layer surface and preparation method thereof

A transfer coating and transfer layer technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of reducing efficiency, difficult to achieve high smoothness on the surface of transfer coating, increasing cost, etc., to achieve good high temperature resistance, Improved surface slip, cost-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

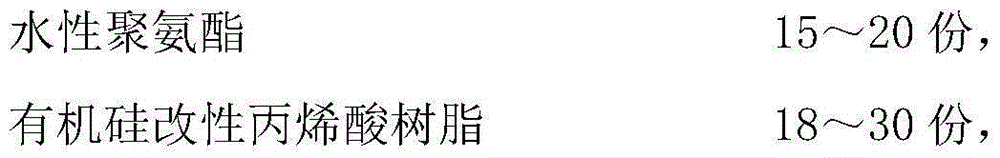

[0032] This embodiment provides a kind of water-based environment-friendly transfer coating with high slipperiness on the surface of the transfer layer. The bottom coating is made of the following components and contents as raw materials:

[0033] Table 1

[0034] components

Embodiment 2

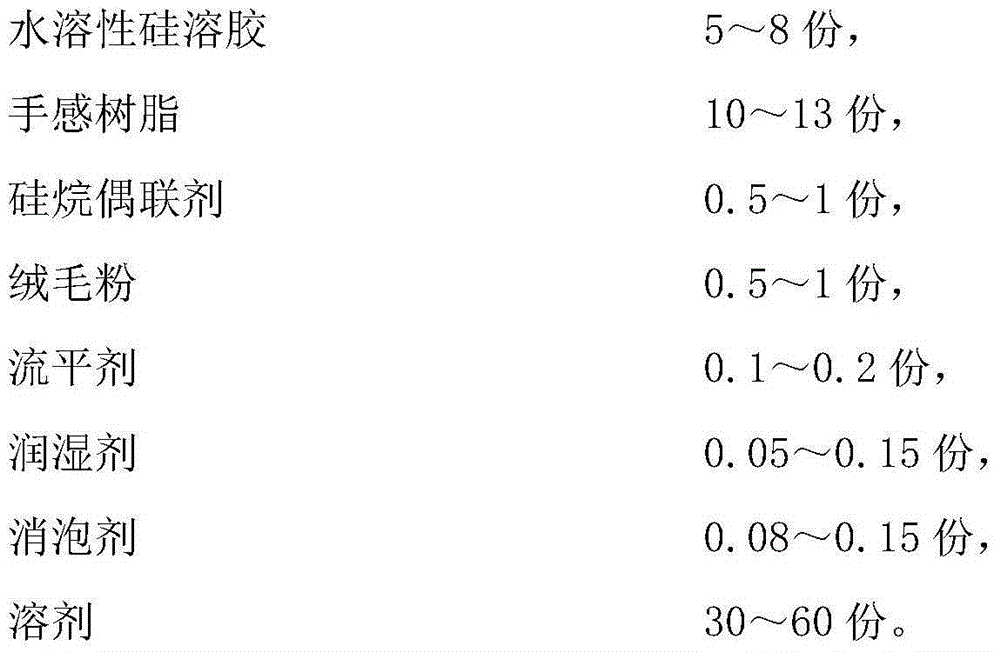

[0036] In this embodiment, a water-based environment-friendly transfer paint with high slipperiness on the surface of the transfer layer is characterized in that the bottom coating is made of the following components and contents as raw materials:

[0037] Table 2

[0038] components

Embodiment 3

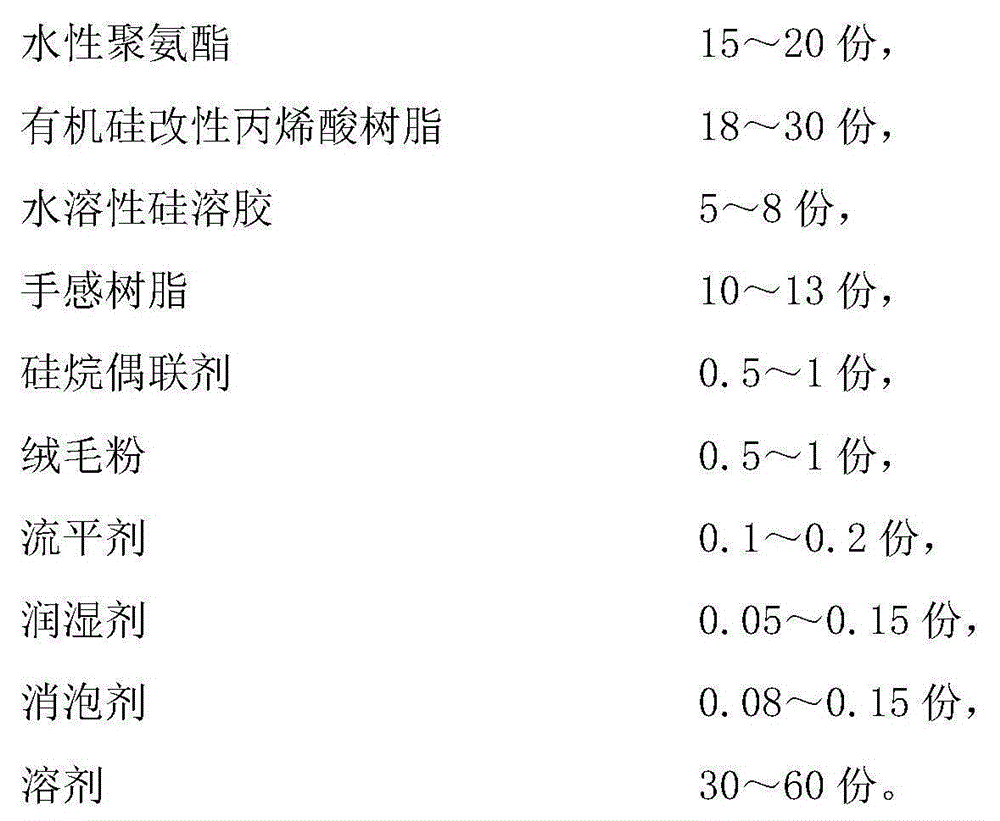

[0040] In this embodiment, a water-based environment-friendly transfer paint with high slipperiness on the surface of the transfer layer is characterized in that the bottom coating is made of the following components and contents as raw materials:

[0041] table 3

[0042] components

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com