Manufacturing method of 3D (three-dimensional) glass plate

A manufacturing method and technology of glass plates, which are applied in the fields of technology for producing decorative surface effects, decorative art, telephone structure, etc., can solve problems such as low production efficiency, glass cracking and breaking, and poor bending accuracy, and achieve improved production Effects on Efficiency and Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

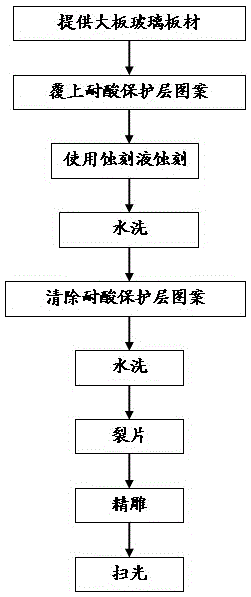

[0041] Example 1: Please refer to figure 1 , A method for manufacturing a 3D glass plate, including the following steps:

[0042] S1 provides large glass plates: a large glass plate is used to make multiple 3D glass plates, and the size of the large glass plate is selected according to the needs. The length and width of the large glass plate are integer multiples of the 3D glass plate to be produced. Its thickness is the same as the thickness of the 3D glass plate to be produced;

[0043] S2 is covered with an acid-resistant protective layer pattern: screen printing an acid-resistant ink protective layer pattern on one surface of the large glass plate, and then dry, the acid-resistant ink protective layer pattern is cured on the surface of the large plate glass plate, so that the surface of the large plate glass plate has several square areas or circles The shaped area is not covered by the acid-resistant ink protective layer;

[0044] S3 uses etching solution to etch: mix the weigh...

Embodiment 2

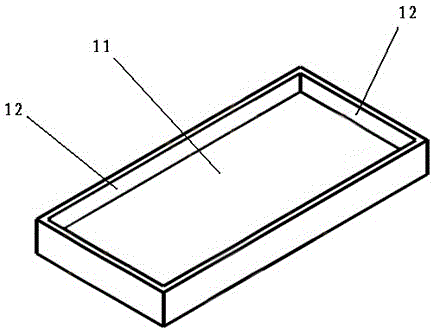

[0051] Example 2: Please refer to figure 2 , A method for manufacturing a 3D glass plate, including the following steps:

[0052] S10 provides large glass plates: choose certain specifications of large glass plates;

[0053] S20 Splinter: Use a cutting machine to split a large glass sheet into several small glass sheets;

[0054] S30 is covered with acid-resistant ink protection layer pattern: screen printing the photosensitive ink protection layer pattern on one side of each small glass plate, expose it on the exposure machine, and use the developer to develop the pattern. The acid-resistant ink protection layer pattern is cured on the side of the small glass plate to make There is a square or circular area on the side of the small glass plate that is not covered by the acid-resistant ink protective layer;

[0055] S40 uses an etching solution to etch: use a 5-25% hydrofluoric acid solution by weight as the etching solution to etch the surface of the small glass plate covered with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com