Single-point nano-welding method based on photothermal effect

A technology of photothermal effect and welding method, applied in laser welding equipment, welding equipment, metal processing equipment, etc., to achieve high scalability, improve optical performance and mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings: the case of this embodiment is based on the single-point nano-welding technology based on the photothermal effect proposed by the present invention, but the scope of protection of the present invention is not limited to the following embodiments and cases .

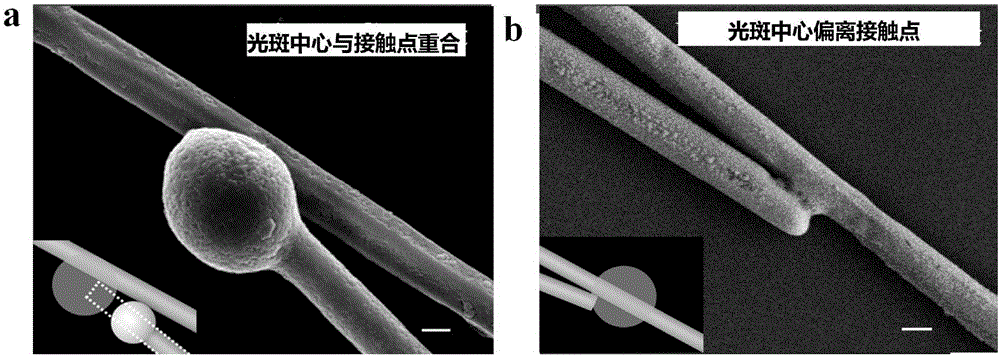

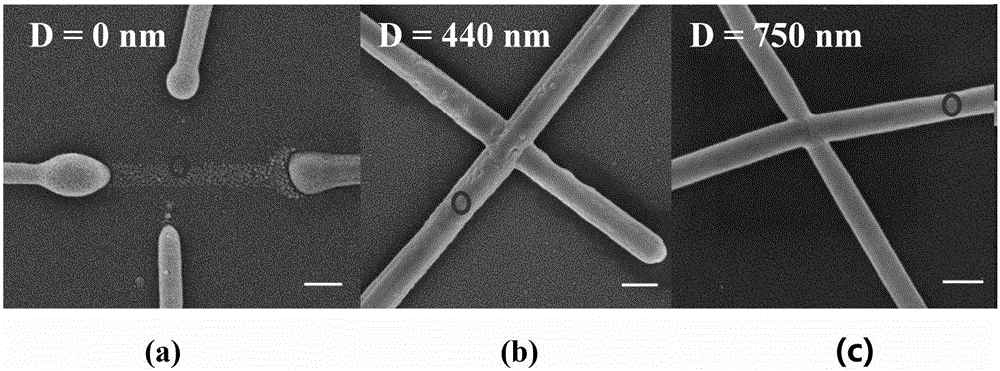

[0023] Such as figure 1 As shown, a single-point nano-welding method based on the photothermal effect uses a device including a monochromatic continuous laser, an optical attenuator, a shutter, a quarter slide, a microscope, a sample stage, and a power meter. The specific welding method is as follows: use the continuous laser to output the monochromatic laser, then adjust the incident power of the monochromatic laser through the beam attenuator, and then use the shutter to control the passing time of the monochromatic laser; then the monochromatic laser passes through a quarter of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com