Tube bending machine applied to steel tube production

A pipe bending machine and steel pipe technology, which is applied in the field of pipe bending machines, can solve the problems affecting the normal bending and bending accuracy of steel pipes, reduce production efficiency, and low efficiency, and achieve the solution of steel pipe bending problems, high degree of automation, and simple machine structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

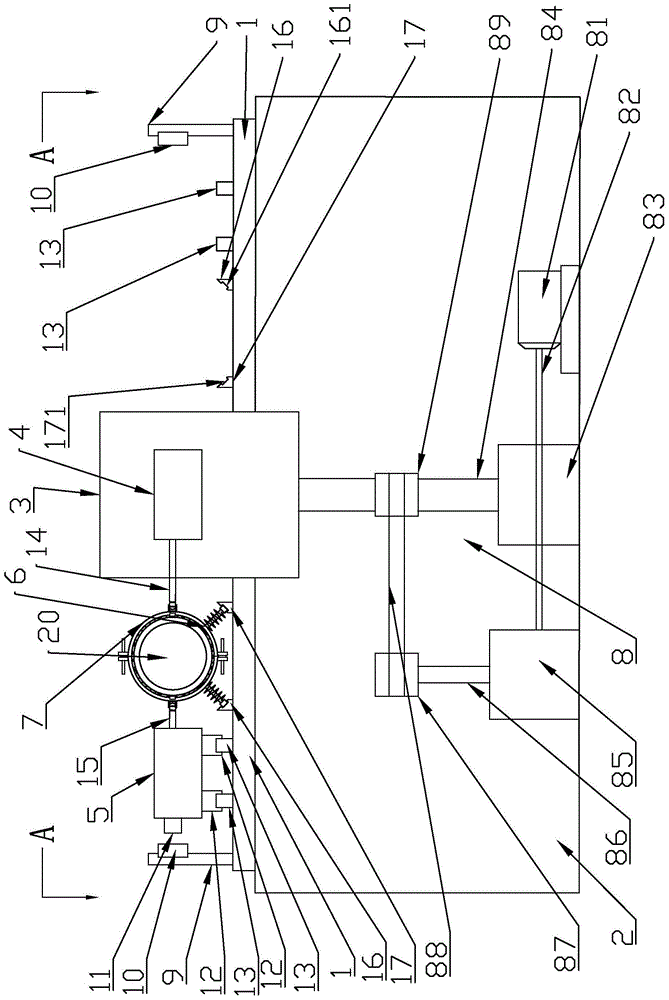

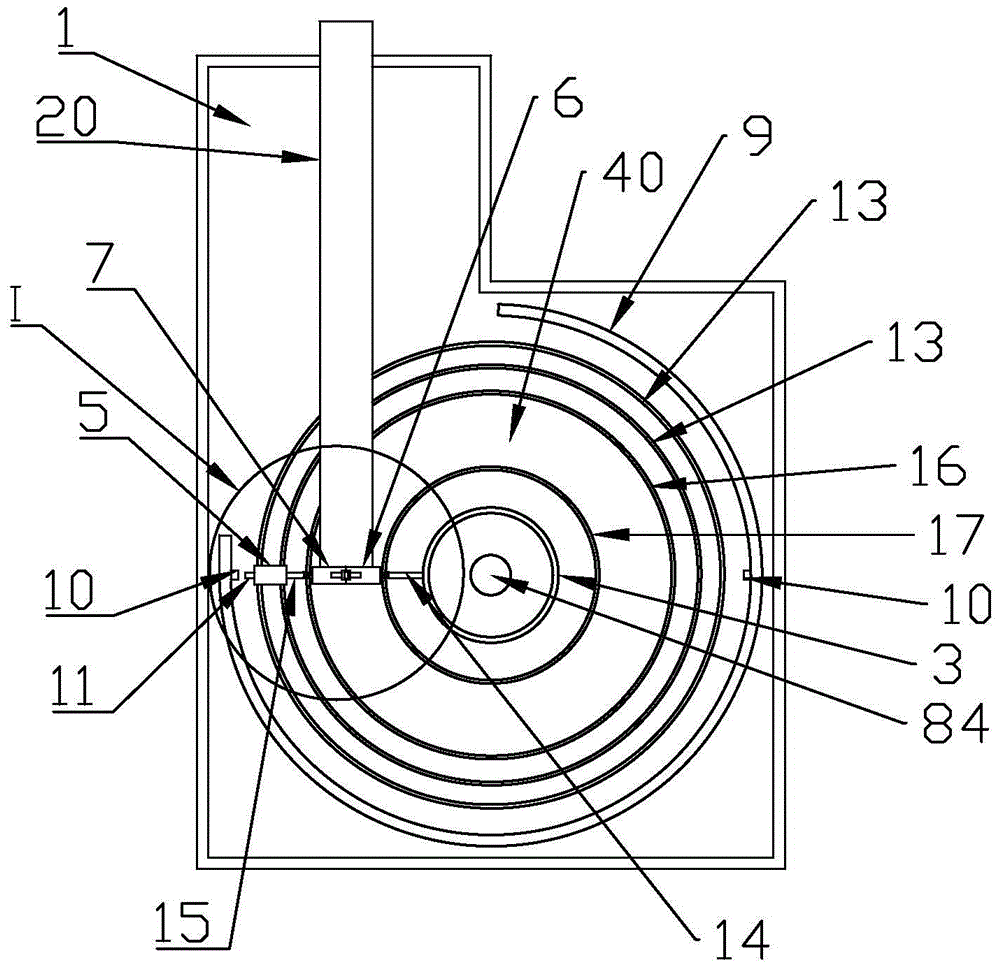

[0030] like Figure 1 to Figure 8 As shown, a pipe bending machine used in the production of steel pipes includes a frame 2 and a workbench 1. The workbench 1 is located on the frame 2, and the workbench 1 is provided with a bending guide rail 13 and a bending table 3. The outside of the workbench 1 is provided with an arc-shaped photoelectric switch fixing plate 9, and the arc-shaped photoelectric switch fixing plate 9 is provided with a photoelectric switch 10, and the side of the outer clamping control room 5 is provided with a stopper 11, and the photoelectric switch 10 and the stopper 11 matches. By installing the arc-shaped photoelectric switch fixing plate 9 on the outside of the bending table 3, when the bent pipe 20 enters the bending space 40, the photoelectric switch 10 sends a signal to start working, and immediately starts the first cylinder 41 and the second cylinder of the clamping device 42. Clamp the pipe 20 to be bent, and reflect the degree of clamping thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com