Metal spraying process and mobile phone shell

A metal spraying and process technology, which is applied in the directions of coating, telephone structure, and device for coating liquid on the surface, can solve the problems of high manufacturing cost of mobile phone case, complicated process, poor spraying effect, etc., to reduce spraying cost, The effect of simplifying the spraying process, good spraying results and environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

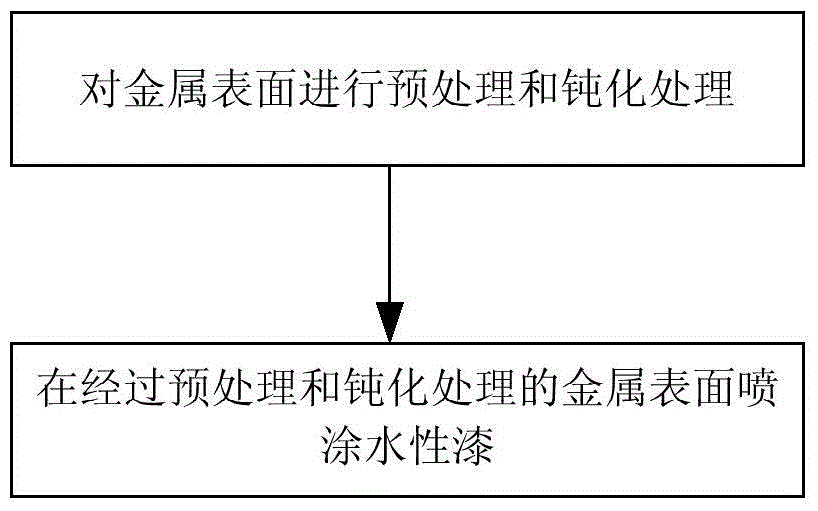

[0018] Such as figure 1 As shown, in this embodiment, a metal spraying process is provided, including pretreatment and passivation treatment on the metal surface, wherein the water-based paint is sprayed on the pretreated and passivation treated metal surface.

[0019] Water-based paint uses clear water as the diluent and does not contain harmful solvents. It will not cause environmental pollution before and after construction, and will not endanger human health. The discharged VOC content is better than the requirements of environmental standards, and the performance indicators of the product are better than those of similar solvent-based paints. Water-based baking varnish is not easy to burn, and it is non-toxic and odorless. It is a brand new environmental protection product. And spraying with water-based paint can reduce the cost of spraying and simplify the process of spraying.

[0020] It should be noted that water-based paint is a new type of environmentally friendly ...

Embodiment 2

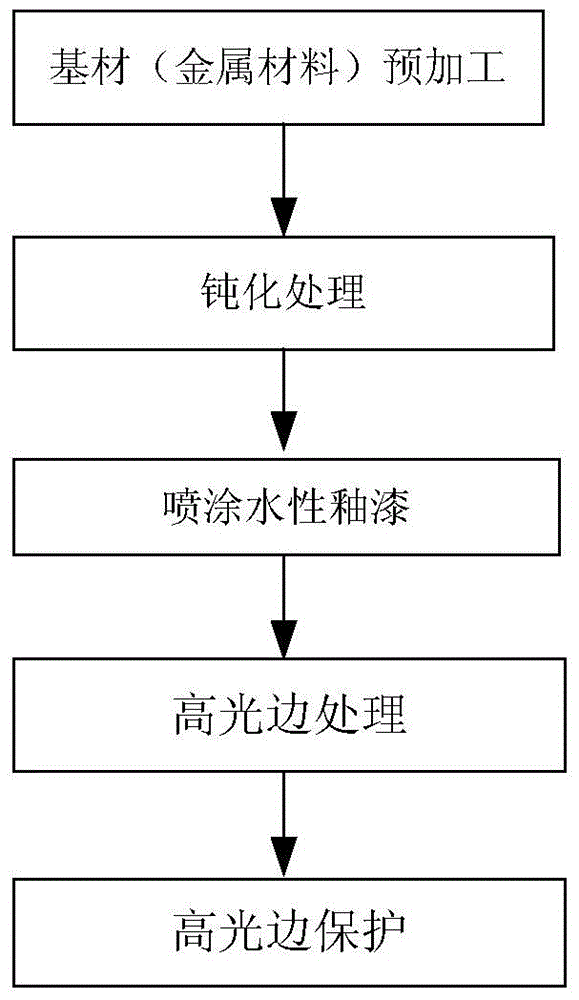

[0034] refer to figure 2 In order to further explain the above-mentioned metal spraying process, in this embodiment, a specific implementation of the above-mentioned metal spraying process is also provided, which includes the following steps:

[0035] Step 1: Substrate (metal material) preprocessing:

[0036] The metal material can be die-cast aluminum alloy, stretched aluminum alloy, stainless steel, zinc alloy or magnesium alloy, etc.;

[0037] Pretreatment process, including rough machining, grinding, polishing and other processes, mainly removes the surface waste, and then polishes the surface;

[0038] Step 2: Passivation treatment: Passivate the metal surface to form an oxide film on the surface;

[0039] Step 3: Spray water-based glaze paint: the paint contains silver powder particles, so that it has a metallic effect after spraying;

[0040] Step 4: High-gloss edge treatment: After painting, do CNC high-gloss edge, and use CNC high-speed cutting processing;

[004...

Embodiment 3

[0048] In this embodiment, another method of spraying water-based glaze paint is provided, which specifically includes the following steps:

[0049] Step a: Spray the bottom glaze water-based paint: 95 parts of glaze to 5 parts of clean water, stir for 5 minutes, filter through a 300-mesh filter, and finely defoam for 5 minutes; after spraying, it will naturally level for 8 seconds and put it in a 50°C oven for 3 minutes;

[0050] Step b: Spray medium-glaze water-based paint: 95 parts of glaze to 5 parts of clean water, stir for 5 minutes, filter through a 300-mesh filter, and finely defoam for 5 minutes; after spraying, it will naturally level for 8 seconds and put it in a 50°C oven for 3 minutes;

[0051] Step c: Spray the top glaze water-based paint: 100 parts of glaze to 5 parts of clean water, stir for 5 minutes, filter through a 300-mesh filter, and finely defoam for 5 minutes; after spraying, put it in a 50°C oven for 8 seconds and slowly Raise the temperature to 180°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com