3D glass ink spraying device and spraying method

A spraying device and glass technology, applied in the direction of coating, etc., can solve the problems of low spraying efficiency and cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

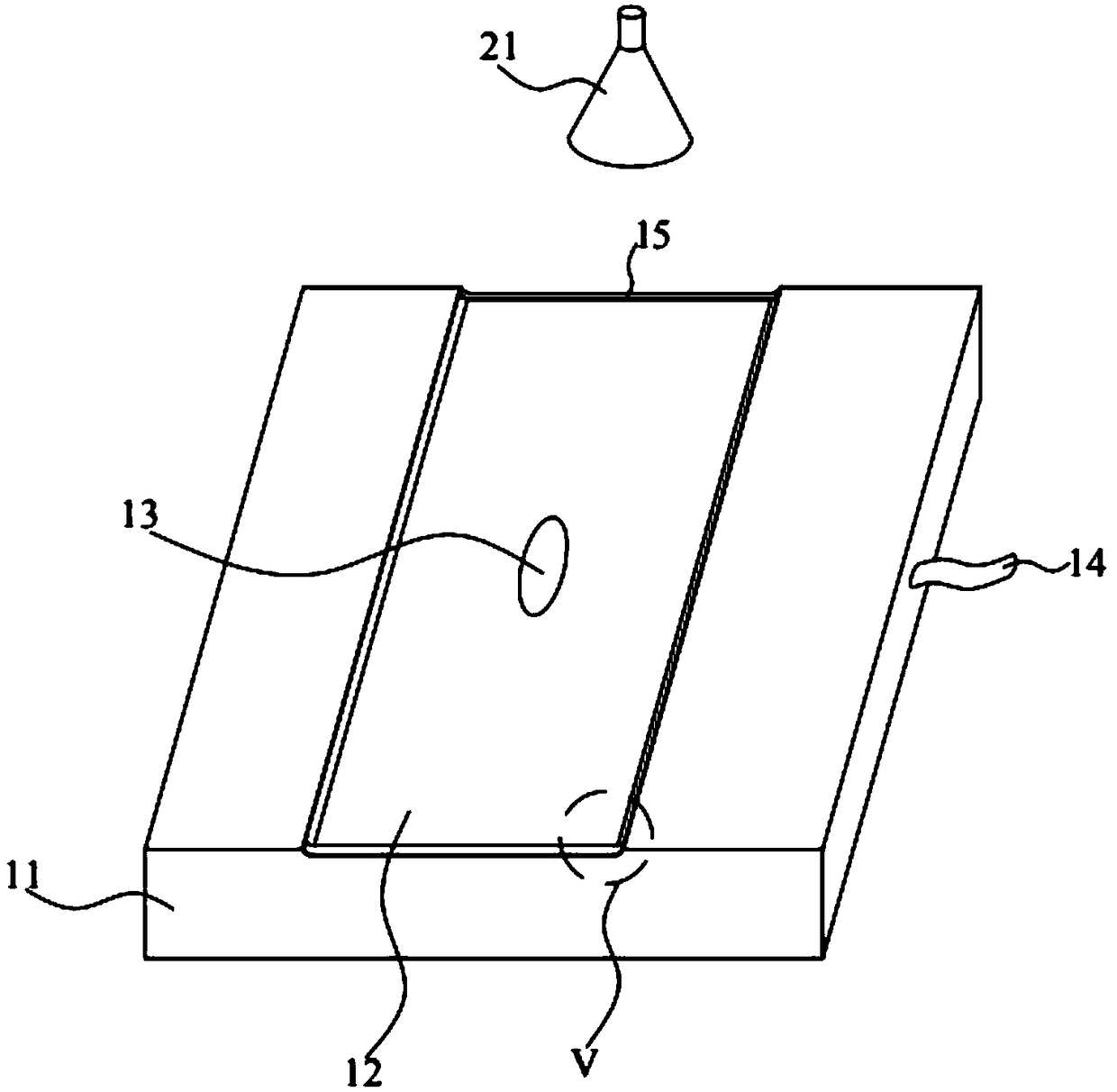

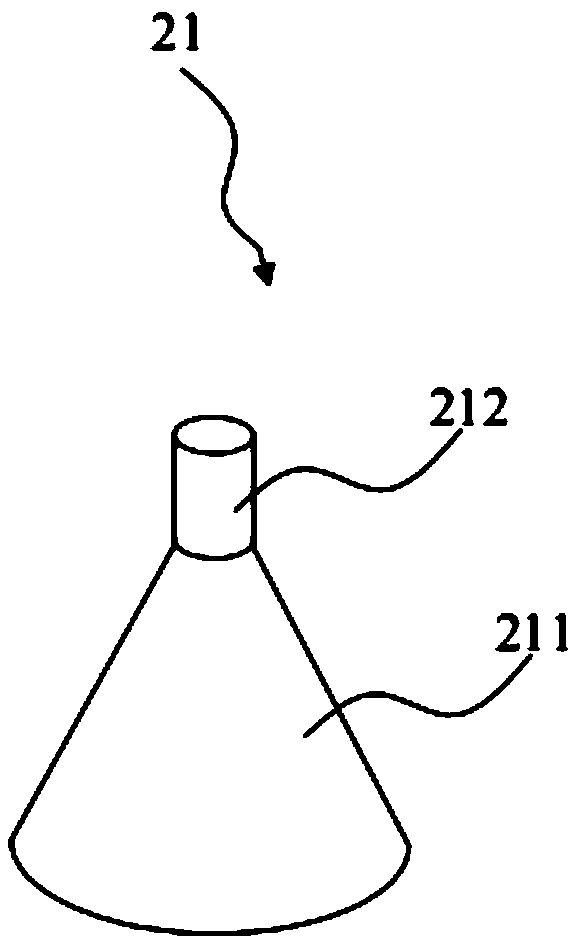

[0036] In order to solve this technical problem, the present invention proposes an ink spraying device for 3D glass, please refer to Figure 1 to Figure 5 , the 3D glass ink spraying device proposed in the first embodiment of the present invention includes a hollow box 11 and a suction cup 21 .

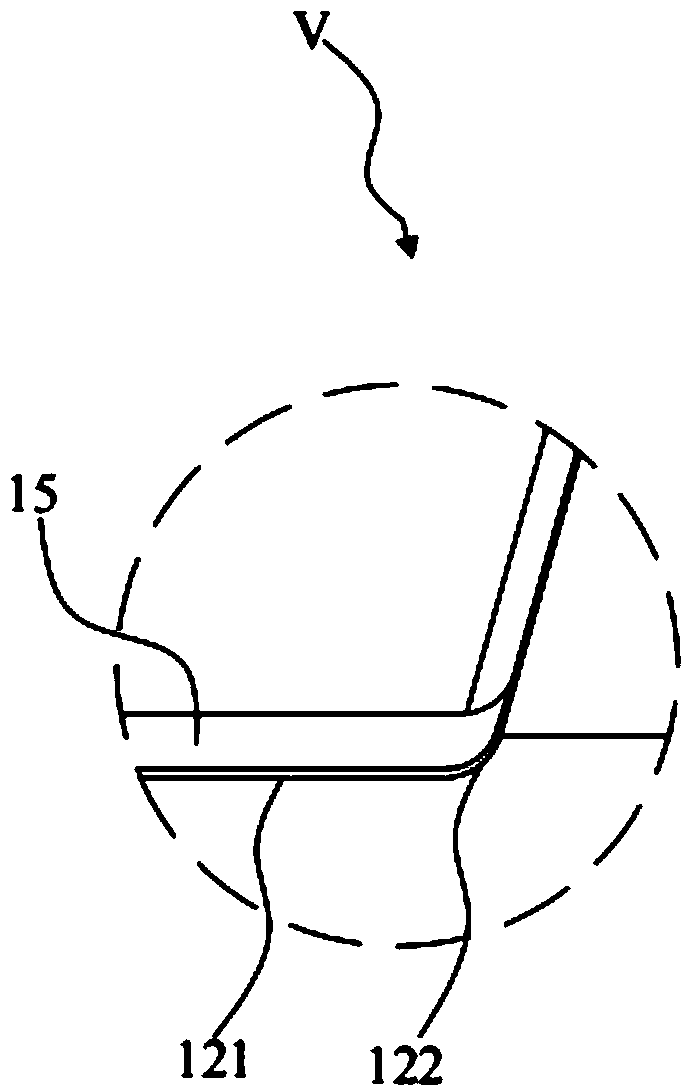

[0037] From figure 1 It can be seen from the figure that a storage tank 12 for fixedly placing 3D glass is provided on the top of the hollow box 11, and a negative pressure through hole 13 is also provided on the top surface of the hollow box 11, and the negative pressure through hole 13 is set In the area where the storage tank 12 is located.

[0038] In order to form a negative pressure in the above-mentioned hollow box 11, in this embodiment, a negative pressure conduit 14 is provided on one side of the hollow box 11, and the negative pressure conduit 14 is connected with the above-mentioned hollow box 11, One end of the negative pressure conduit 14 is connected to a suction moto...

Embodiment 2

[0046] The present invention also proposes an ink spraying method for 3D glass, wherein, please refer to Figure 6 , using the above ink spraying device to spray 3D glass, the method includes the following steps:

[0047] S101, place the 3D glass in the storage slot on the hollow box, and absorb the air in the hollow box through the negative pressure conduit, so that the 3D glass and the storage slot are closely attached.

[0048] In this step, it should be pointed out that when placing the 3D glass in the storage tank, it is necessary to ensure that the above-mentioned glass flat part 31 corresponds to the position of the straight part 121 of the groove surface, and the glass curved part 32 corresponds to the position of the curved part of the groove surface. 122 is correspondingly attached, and the portion 322 to be sprayed on the 3D glass 30 is positioned at the outside of the storage tank 12 (see figure 2 and Figure 5 ). Then the air in the hollow box is absorbed thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com