Preparation method of defoaming agent for waterborne system

A technology of water-based system and defoamer, which is applied in the field of water-based defoamer and modified silicone defoamer, can solve the problems of low foam breaking rate and polyether defoamer to eliminate foam, and achieve long foam suppression time, Rapid defoaming and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the defoamer for aqueous system described in the present application, comprises the steps:

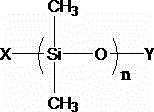

[0041] 1) Add silicone oil, fumed silica, and catalyst into the reaction vessel according to the comparison, raise the temperature to 80-200°C under nitrogen protection and stirring, and react for 2-10 hours to prepare silicone paste;

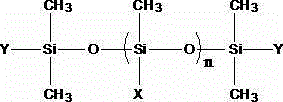

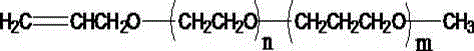

[0042] 2) Add hydrogen-containing silicone oil and allyl polyether into the reaction vessel according to the proportion, stir under nitrogen protection, heat up to 65~120°C, add initiator and react for 2.5~12 hours to prepare polyether modified silicone;

[0043] 3) Add the silicone paste obtained in step 1), the polyether modified silicone obtained in step 2), and the emulsifier into the reaction vessel, add water to emulsify under high-speed stirring, and add a thickener to adjust the viscosity to 750~1300mpa.s to obtain product

[0044] In the preparation method of the defoamer for aqueous system according to the pre...

Embodiment 1

[0054] The preparation method of the defoamer for aqueous system described in the present application comprises the steps in turn:

[0055] (1) Add 95 parts of 1000cs simethicone oil, 4 parts of hydrophobic fumed silica, and 1 part of oleic acid into the reaction vessel, heat up to 80°C under stirring conditions, and react for 10 hours to prepare silicone paste;

[0056] (2) According to the molar ratio (-H):(CH2=CH-)=1:1, add 0.18% side chain hydrogen-containing silicone oil and allyl polyether (n:m=1:6) into the reaction vessel , stirred under the protection of nitrogen, heated up to 65°C, added 10ppm Cateser zero-valent platinum complex initiator and reacted for 12h to prepare polyether-modified silicone;

[0057] (3) Mix 2.5 parts of homemade silicone paste, 4.8 parts of homemade polyether modified silicone, 1 part of sorbitan monooleate (S-80), 1 part of sorbitan monostearate polyoxygen Add vinyl ether ester (T-60) into the reaction vessel together, add 90.5 parts of dei...

Embodiment 2

[0059] The preparation method of the defoamer for aqueous system described in the present application comprises the steps in turn:

[0060] (1) Add 94 parts of 1500cs simethicone oil, 5 parts of hydrophilic fumed silica, and 1 part of acetic acid into a reaction vessel, heat up to 200°C under stirring conditions, and react for 2 hours to prepare a silicone paste;

[0061] (2) According to the molar ratio (-H):(CH2=CH-)=1:1, add 0.25% terminal group hydrogen-containing silicone oil and allyl polyether (n:m=1:5) into the reaction vessel , stirred under the protection of nitrogen, heated to 120°C, added 20ppm chloroplatinic acid hydrate initiator and reacted for 2.5h to prepare polyether-modified silicone;

[0062] (3) Mix 2 parts of homemade silicone paste, 5.5 parts of homemade polyether modified silicone, 1 part of sorbitan monostearate (S-60), 0.5 part of sorbitan monostearate poly Add oxyethylene ether ester (T-60) into the reaction vessel together, add 90.5 parts of deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com