Porous CoV2O6 nanosheet electrode material and preparation method and application thereof

An electrode material and nanosheet technology, applied in the field of nanomaterials and electrochemistry, can solve the problems of volume expansion, low electronic conductivity of cobalt oxide, and destroy cycle performance, and achieve easy amplification, excellent cycle stability, and improved The effect of ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Mesoporous CoV 2 o 6 The preparation method of nano sheet, it comprises the steps:

[0028] 1) First add 0.08g of acetylene black to 20ml of water and stir, then add 0.9963g of cobalt acetate and stir for 2 hours, so that the acetylene black can be completely immersed in water;

[0029] 2) Add 0.9385g of ammonium metavanadate to 20mL of deionized water, dissolve in a water bath at 85°C, add the resulting solution dropwise to the solution obtained in step 1), and stir together for 5 hours at room temperature to obtain a precursor;

[0030] 3) Dry the obtained precursor in a water bath at 85°C, and after grinding, calcinate at 450°C for 10 hours in air to obtain a yellow porous CoV 2 o 6 Nanosheet electrode anode material.

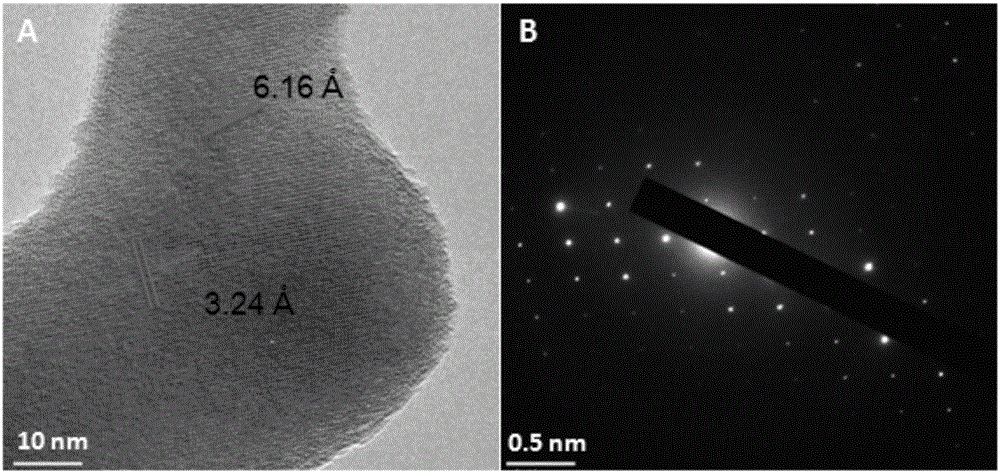

[0031] Porous CoV as the product of this example 2 o 6 Taking nanosheet material as an example, the structure was determined by X-ray diffractometer. attached figure 1 The X-ray diffraction pattern (XRD) shown shows that the porous CoV 2 o 6...

Embodiment 2

[0036] 1) First add 0.15g of acetylene black to 20ml of water and stir, then add 0.9963g of cobalt acetate and stir for 2 hours, so that the acetylene black can be completely immersed in water;

[0037] 2) Add 0.9385g of ammonium metavanadate to 20mL of deionized water, dissolve in a water bath at 85°C, add the resulting solution dropwise to the solution obtained in step 1), and stir together for 5 hours at room temperature to obtain a precursor;

[0038] 3) Dry the obtained precursor in a water bath at 85°C, and after grinding, calcinate at 450°C for 10 hours in air to obtain a yellow porous CoV 2 o 6 Nanosheet electrode anode material.

[0039] The porous CoV obtained in this example 2 o 6 Taking nanosheet material as an example, at a current density of 5A / g, the initial discharge capacity of the material is 690mAh / g, and the discharge capacity after 500 cycles can still reach 399mAh / g, and the capacity retention rate is 57.8%.

Embodiment 3

[0041] 1) First add 0.08g of acetylene black to 20ml of water and stir, then add 2g of cobalt acetate and stir for 2 hours, so that the acetylene black can be completely immersed in water;

[0042] 2) Add 2g of ammonium metavanadate to 20mL of deionized water, dissolve in a water bath at 85°C, add the resulting solution dropwise to the solution obtained in step 1), and stir together for 5 hours at room temperature to obtain a precursor;

[0043] 3) Dry the obtained precursor in a water bath at 85°C, and after grinding, calcinate at 450°C for 10 hours in air to obtain a yellow porous CoV 2 o 6 Nanosheet electrode anode material.

[0044] The porous CoV obtained in this example 2 o 6 Taking nanosheet material as an example, at a current density of 5A / g, the initial discharge capacity of the material is 589mAh / g, and the discharge capacity after 500 cycles can still reach 302mAh / g, and the capacity retention rate is 51.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com