Al component gradually-changed N-type LED structure and preparation method thereof

A LED structure and component gradual change technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of no application, etc., and achieve the effects of improving surface roughness, increasing electron concentration, and enhancing current expansion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

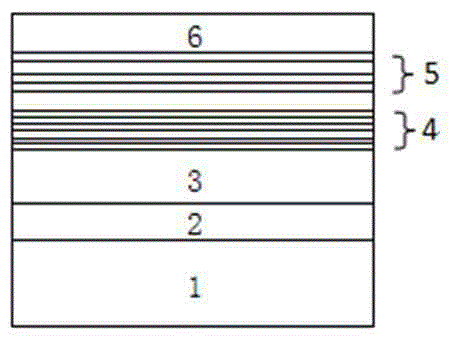

[0036] Such as figure 1 , taking the preparation of an N-type GaN structure on a silicon carbide substrate by metal-organic chemical vapor deposition as an example, which specifically includes the following steps:

[0037] (1) The silicon carbide substrate 1 is placed in the reaction chamber of the metal organic chemical vapor deposition furnace (MOCVD) equipment, heated to 800° C. under a hydrogen atmosphere, and processed for 15 minutes;

[0038] (2) growing an aluminum nitride nucleation layer 2 on a silicon carbide substrate 1 at a growth temperature of 450° C. and a thickness of 60 nm;

[0039] (3) growing a non-doped gallium nitride layer buffer layer 3 on the aluminum nitride nucleation layer 2, the growth temperature is 1150° C., and the growth thickness is 50 nm;

[0040] (4) N-type Al is grown on the gallium nitride buffer layer 3 Y In X Ga 1‐X‐Y For the N layer 4, set the growth temperature to 750° C., the growth pressure to 800 torr, and the growth time to 200 ...

Embodiment 2

[0044] Such as figure 1 , taking the preparation of an LED structure on a sapphire substrate by metal-organic chemical vapor deposition as an example, which specifically includes the following steps:

[0045] (1) The sapphire substrate 1 is placed in the reaction chamber of a metal organic chemical vapor deposition furnace (MOCVD), heated to 1300° C. under a hydrogen atmosphere, and processed for 5 minutes;

[0046] (2) growing an AlGaN nucleation layer 2 on a sapphire substrate 1 at a growth temperature of 650° C. and a thickness of 10 nm;

[0047] (3) growing a non-doped GaN layer buffer layer 3 on the AlGaN nucleation layer 2, the growth temperature is 800°C, and the growth thickness is 2000nm;

[0048] (4) N-type Al is grown on the gallium nitride buffer layer 3 Y In X Ga 1‐X‐Y For the N layer 4, set the growth temperature to 1600° C., the growth pressure to 200 torr, and the growth time to 3000 s. When growing, turn on the required silane for 1500s, and the silicon d...

Embodiment 3

[0053] Such as figure 1 , taking the preparation of an N-type superlattice structure on a sapphire substrate by metal-organic chemical vapor deposition as an example, which specifically includes the following steps:

[0054] (1) The sapphire substrate 1 is placed in the reaction chamber of a metal organic chemical vapor deposition furnace (MOCVD), heated to 1000° C. under a hydrogen atmosphere, and processed for 10 minutes;

[0055] (2) growing a gallium nitride nucleation layer 2 on a sapphire substrate 1 at a growth temperature of 550° C. and a thickness of 30 nm;

[0056] (3) growing a non-doped gallium nitride layer buffer layer 3 on the gallium nitride nucleation layer 2, the growth temperature is 1080°C, and the growth thickness is 1000nm;

[0057] (4) N-type Al is grown on the gallium nitride buffer layer 3 Y In X Ga 1‐X‐Y For the N layer 4, set the growth temperature to 1005° C., the growth pressure to 500 torr, and the growth time to 1500 s. When growing, turn on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com