Preparation method for porous carbon nanofiber dye-sensitized solar cell counter electrode material doped with sulfur-copper-indium nanocrystalline

A technology of solar cells and nanofibers, applied in the field of solar cells, can solve the problems of expensive platinum electrodes, and achieve the effects of permeation and rapid electron transmission, high photoelectric conversion efficiency, large specific surface area and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

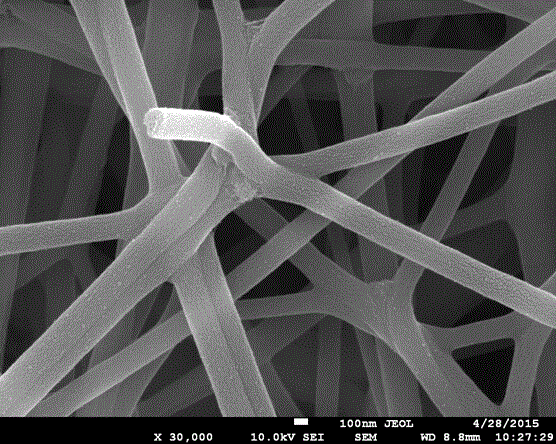

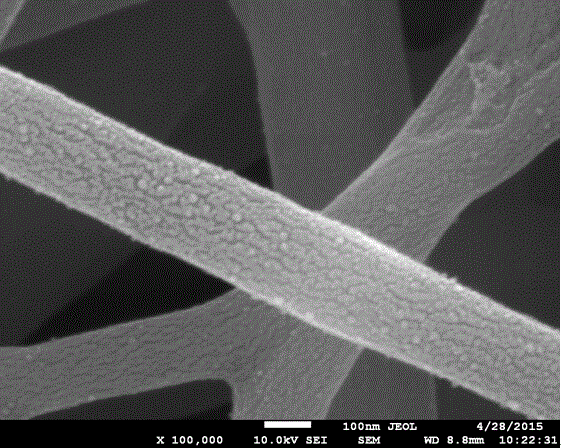

[0021] A method for preparing a porous carbon nanofiber material doped with copper-sulfur-indium nanocrystals, comprising the following steps:

[0022] (1) Use a mixed solution of dimethylformamide and chloroform as the solvent, and the mass ratio of dimethylformamide and chloroform is 9:1. Add copper chloride (CuCl 2 ), indium chloride (InCl 3 ) and thiourea (CN 2 h 4 S), stirring at 40°C for 3h to obtain a copper-sulfur-indium precursor;

[0023] (2) Add polyacrylonitrile powder to the copper-sulfur-indium precursor solution obtained in step (1), and stir at 60° C. for 3 hours to obtain a spinning solution. The molecular weight of described polyacrylonitrile is 50000, and the massfraction of polyacrylonitrile is 5%;

[0024] (3) Electrospinning the spinning solution obtained in step (2) to obtain a nanofiber mat containing copper-sulfur-indium precursor, spinning voltage: 10kV, spinning temperature: 20°C, receiving distance: 10cm;

[0025] (4) Pre-oxidize the nanofiber...

Embodiment 2

[0029] A method for preparing a porous carbon nanofiber material doped with copper-sulfur-indium nanocrystals, comprising the following steps:

[0030] (1) Use a mixed solution of dimethylformamide and chloroform as the solvent, and the mass ratio of dimethylformamide and chloroform is 7:1. Add copper chloride (CuCl 2 ), indium chloride (InCl 3 ) and thiourea (CN 2 h 4 S), stirring at 60°C for 4h to obtain a copper-sulfur-indium precursor;

[0031] (2) Add polyacrylonitrile powder to the copper-sulfur-indium precursor solution obtained in step (1), and stir at 60° C. for 5 hours to obtain a spinning solution. The molecular weight of described polyacrylonitrile is 70000, and the massfraction of polyacrylonitrile is 10%;

[0032] (3) Electrospinning the spinning solution obtained in step (2) to obtain a nanofiber mat containing copper-sulfur-indium precursor, spinning process parameters: voltage: 15kV, temperature: 20°C, receiving distance: 15cm;

[0033] (4) Pre-oxidize t...

Embodiment 3

[0037] A method for preparing a porous carbon nanofiber material doped with copper-sulfur-indium nanocrystals, comprising the following steps:

[0038] (1) Use a mixed solution of dimethylformamide and chloroform as the solvent, and the mass ratio of dimethylformamide and chloroform is 6:1. Add copper chloride (CuCl 2 ), indium chloride (InCl 3 ) and thiourea (CN 2 h 4 S), stirring at 70°C for 5h to obtain a copper-sulfur-indium precursor;

[0039] (2) Add polyacrylonitrile powder to the copper-sulfur-indium precursor solution obtained in step (1), and stir at 70° C. for 4 hours to obtain a spinning solution. The molecular weight of described polyacrylonitrile is 100000, and the massfraction of polyacrylonitrile is 12%;

[0040] (3) Electrospinning the spinning solution obtained in step (2) to obtain a nanofiber mat containing copper-sulfur-indium precursor, spinning process parameters: voltage: 20kV, temperature: 25°C, receiving distance: 30cm;

[0041] (4) Pre-oxidize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com