Preparation method of chalcogenide glass tapered fibers

A technology of chalcogenide glass and tapered optical fiber, which is applied in glass manufacturing equipment, manufacturing tools and other directions, can solve the problems of restricting the application and development of chalcogenide glass tapered fiber, low mechanical strength, poor controllability, etc. The effect of short production cycle and reduced mode field area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The chalcogenide glass (Ge 10 Sb 20 Se 70 ) the preparation method of tapered optical fiber, comprises the steps:

[0024] 1) in Ge 10 Sb 20 Se 70 The cylindrical surface of the chalcogenide glass optical fiber preform is wound to form a polyethersulfone resin layer with a certain thickness. Stable and uniform drawing at 340°C to form chalcogenide glass optical fibers with an outer diameter of several hundred meters in the range of 250-330 μm;

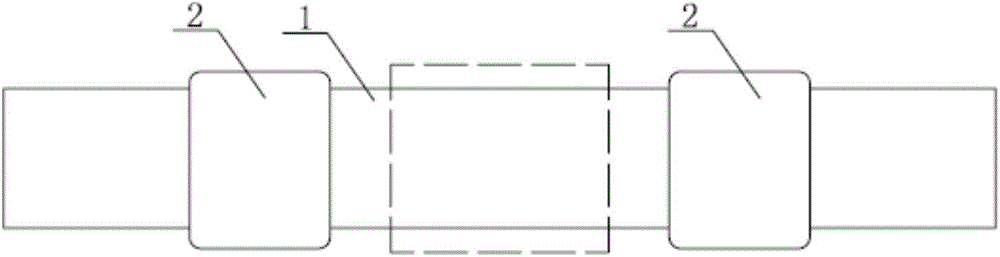

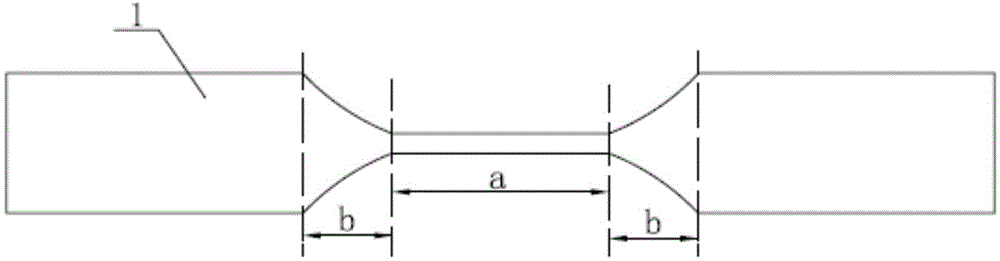

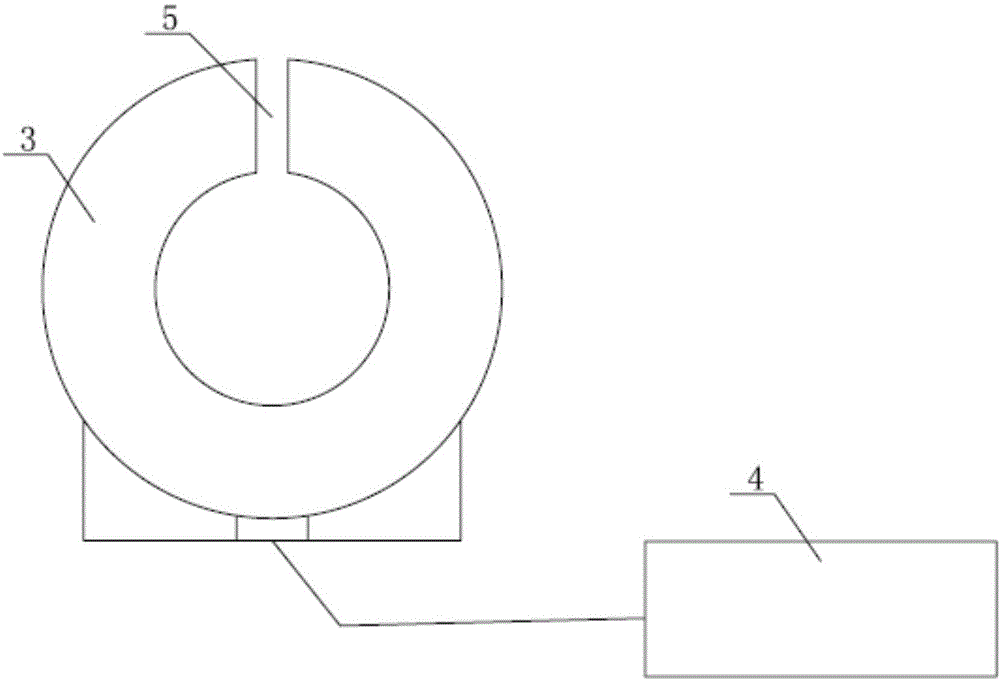

[0025] 2) Cut a section of about 10 cm in length from the above-mentioned chalcogenide glass optical fiber, and then fix the two ends of the section of optical fiber with optical fiber clamps, such as figure 1 as shown, figure 1 Among them, 1 is the optical fiber before tapering, and 2 is the optical fiber clamp. The optical fiber clamp 2 is connected to the output end of the stepping motor (not shown in the figure). The pulling speed of the stepping motor is controllable, and the sulfur can be controlled by the stepping ...

Embodiment 2

[0028] Ge of Example 2 15 Sb 10 Se 75 The preparation method of chalcogenide glass tapered optical fiber comprises the following steps:

[0029] 1) in Ge 15 Sb 10 Se 75 The cylindrical surface of the chalcogenide glass optical fiber preform is wound to form a polyetherimide resin layer with a certain thickness, and the measured outer diameter is Ф26mm, and then the chalcogenide glass optical fiber preform is placed on the fiber drawing tower in an inert gas atmosphere protection environment , drawn at 360°C at a stable and uniform speed to form a chalcogenide glass optical fiber with a length of several hundred meters and an outer diameter in the range of 250-330 μm;

[0030] 2) Cut a section of about 10cm in length from the above-mentioned chalcogenide glass optical fiber, and then fix the two ends of the section of optical fiber with optical fiber clamps. The optical fiber clamps are connected to the output end of the stepping motor, and the pulling speed of the steppin...

Embodiment 3

[0033] Ge of Example 3 17 Ga 4 Sb 10 Se 69 The preparation method of chalcogenide glass tapered optical fiber comprises the following steps:

[0034] 1) in Ge 17 Ga 4 Sb 10 Se 69 The cylindrical surface of the chalcogenide glass optical fiber preform is wound to form a polyetherimide resin layer with a certain thickness, and the measured outer diameter is Ф26mm, and then the chalcogenide glass optical fiber preform is placed on the fiber drawing tower in an inert gas atmosphere protection environment , drawn at 420°C at a stable and uniform speed to form a chalcogenide glass optical fiber with a length of several hundred meters and an outer diameter in the range of 250-330 μm;

[0035] 2) Cut a section of about 10cm in length from the above-mentioned chalcogenide glass optical fiber, and then fix the two ends of the section of optical fiber with optical fiber clamps. The optical fiber clamps are connected to the output end of the stepping motor, and the pulling speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com