The processing method of the multi-pole magnetic ring used in the motor

A multi-pole magnetic ring, processing method technology, applied in the direction of inductor/transformer/magnet manufacturing, circuits, electrical components, etc., can solve the problems of inability to apply, poor consistency of multi-pole magnetic rings, etc., achieve good orientation consistency, avoid magnetic powder uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

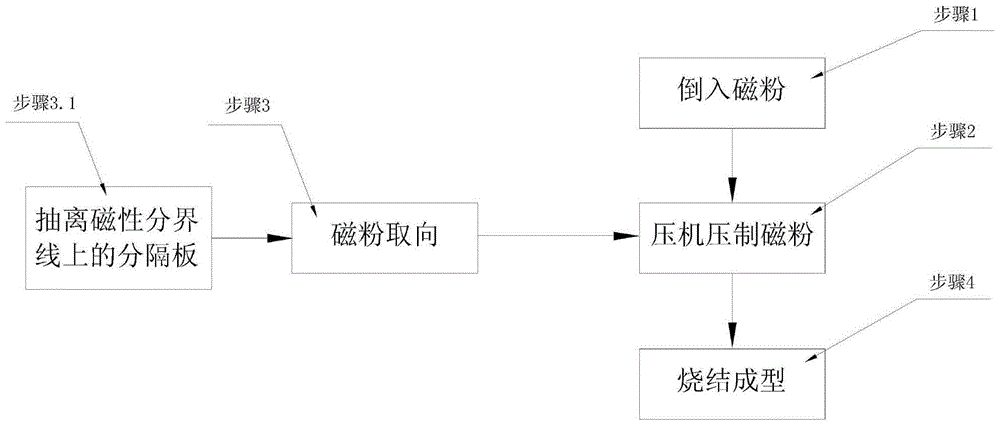

[0026] As shown in the figure, the present invention provides a processing method for a multi-pole magnetic ring on a motor, which includes

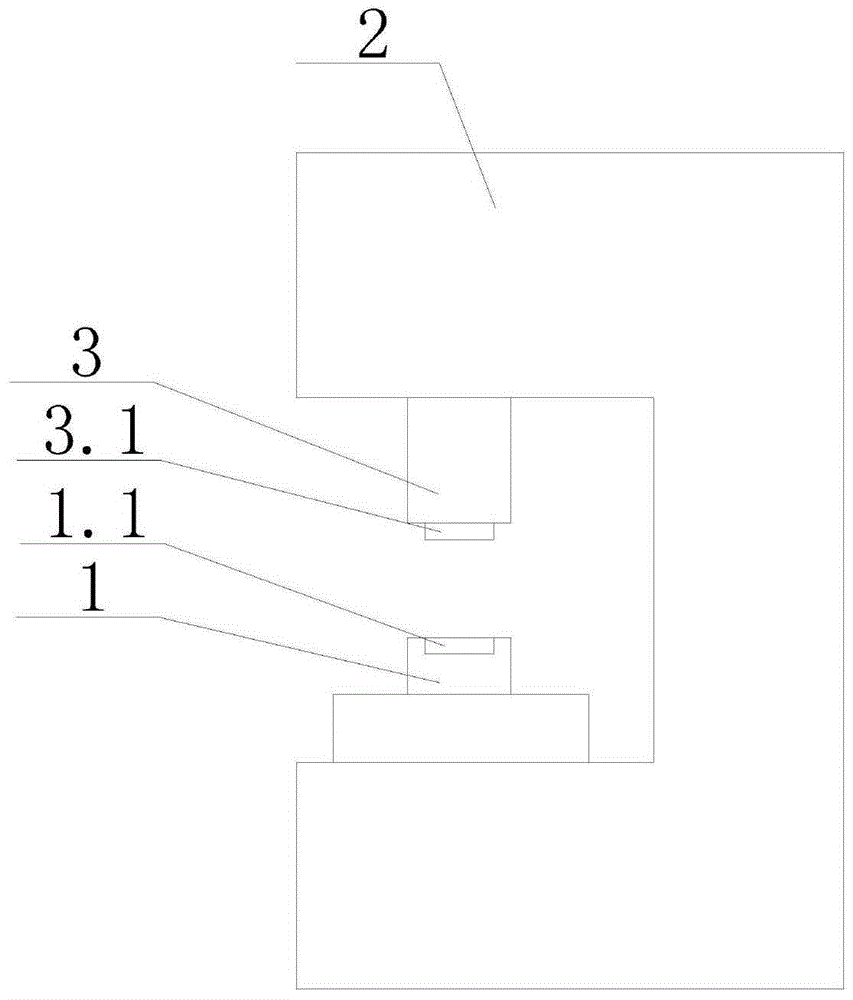

[0027] Step 1, pour the magnetic powder into the concave mold 1.1 on the fixed template 1;

[0028] Step 2, drive the punch 3.1 on the movable template 3 to cooperate with the die 1.1 through the press 2, and compact the magnetic powder;

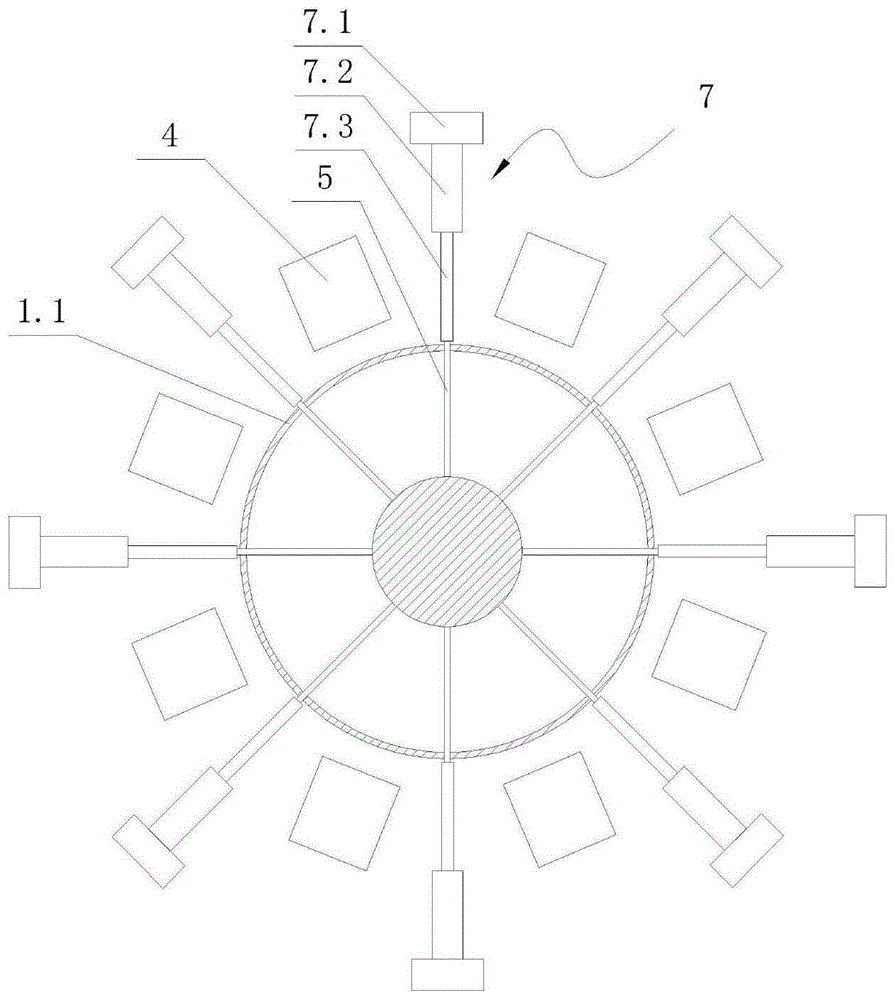

[0029] Step 3, the fixed template 1 is provided with a plurality of orientation electromagnet assemblies 4 along the circumference of the center point of the die 1.1. The number of orientation electromagnet assemblies 4 is the same as the number of magnetic poles required by the product 6. When the press 2 drives the punch 3.1 to approach When the concave mold 1.1 is energized, the orientation electromagnet assembly 4 is energized, and the magnetic powder in each corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com