Sliding rod type wind turbine blade adjusting mechanism

A technology for adjusting mechanisms and wind rotor blades, which is applied in the direction of wind turbines, wind turbine control, engines, etc., can solve problems such as unsatisfactory power generation costs, unsatisfactory blade angle control, and poor synchronization, so as to improve wind energy utilization efficiency and convenience. Routine maintenance, low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

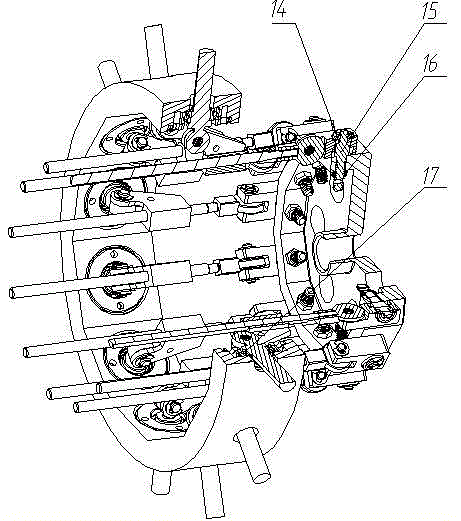

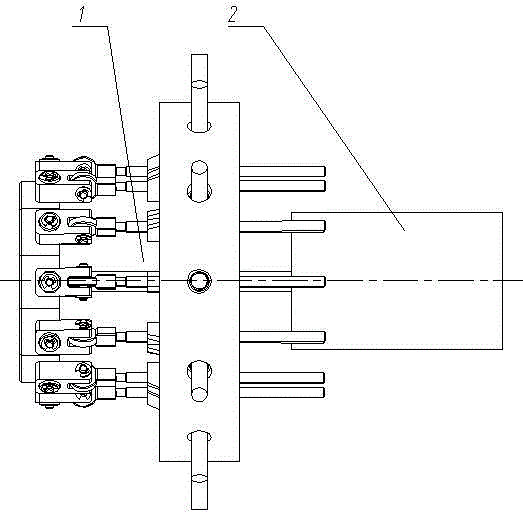

[0018] Depend on Figure 1 to Figure 5 It can be seen that the technical solution of the present invention includes the drive motor fixing disc 9, the adjusting disc 13, the blade shaft 6, the adjusting disc connecting joint 12, the adjusting disc connecting shaft 15, the connecting head 10, the connecting head connecting pin 11, the blade shaft connecting pin 5, Connecting rod 7, slider 8, bearing 17, bearing retaining ring 3, nut 16, gasket 4, flat gasket 14; the power unit 2 is placed on the side of the drive motor fixed disk 9 of the adjustment mechanism 1 as a whole;

[0019] The overall adjustment mechanism 1 is a rocker slider type adjustment mechanism; the power unit 2 for adjusting and controlling the blade angle in this embodiment adopts an electric motor; 13 on the outer side, the connecting head 10 is connected with the adjusting disc connecting joint 12 through the connecting head connecting pin 11, the connecting rod 7 is screwed on the connecting head 10, the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com