Blended and interwoven fabric as well as preparation method thereof

A technology of interwoven fabric and base fabric layer, applied in the field of textile fabrics, can solve the problems of no preparation method, no acid and alkali resistance, antistatic, high and low temperature resistance, narrow use range, etc. Wide and versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of this blended interwoven cloth comprises the following steps:

[0047] A, take the required raw material by the weight part of above each component;

[0048] b. Add the polytetrafluoroethylene concentrated dispersion, crosslinking agent, antistatic agent and antioxidant to the mixer, stir for 5 minutes, and stir at a speed of 100r / min to prepare the finishing solution;

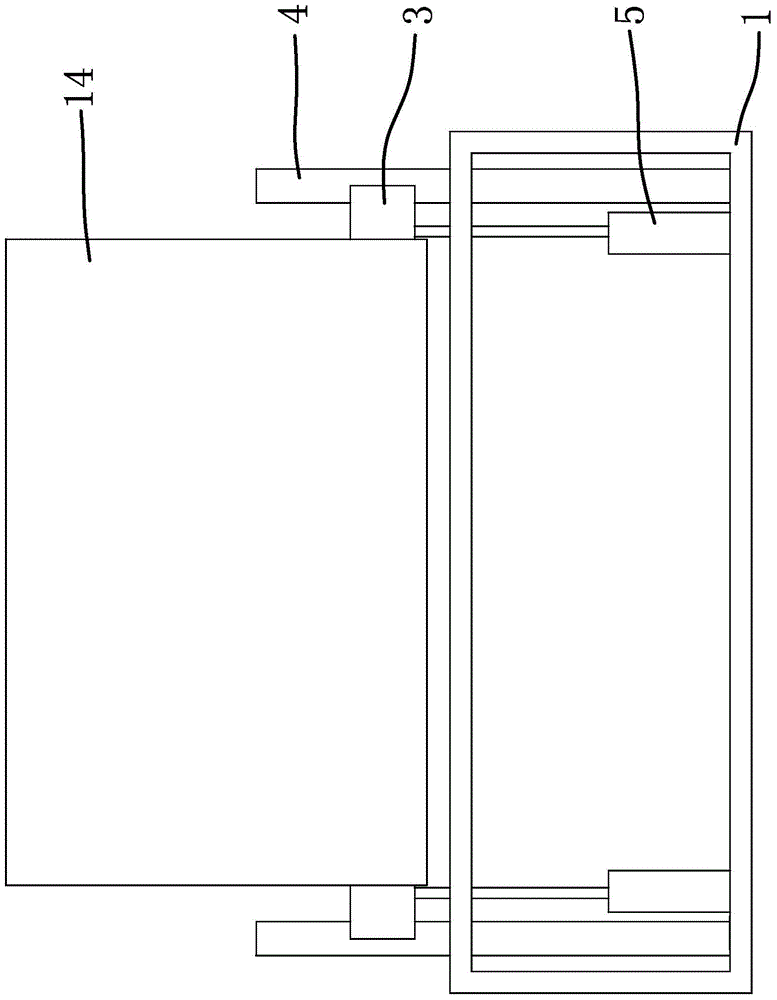

[0049] c. Inject the finishing liquid into the padding tank of the padding equipment, dip the base cloth layer in the padding tank 14, and process it with padding process, the padding speed is 10m / min, and the finishing liquid layer is the protective layer;

[0050] d. Put the padded base fabric layer into an oven for drying treatment at a drying temperature of 100° C. and a drying time of 10 minutes to obtain the blended interwoven fabric.

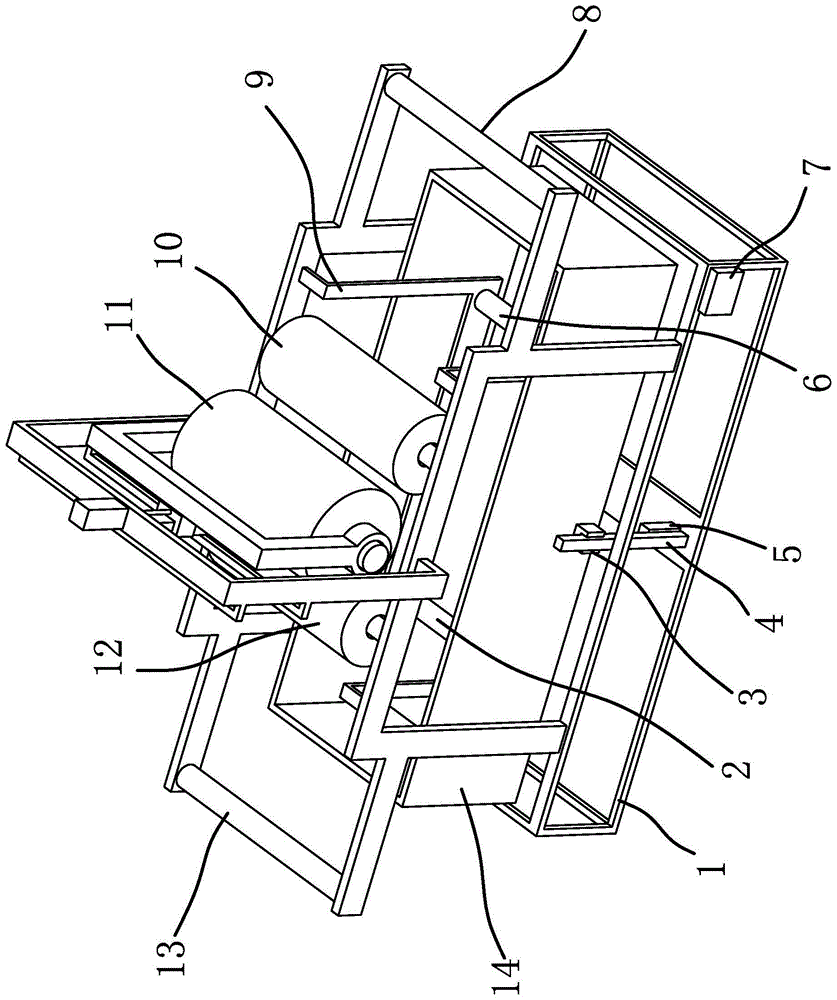

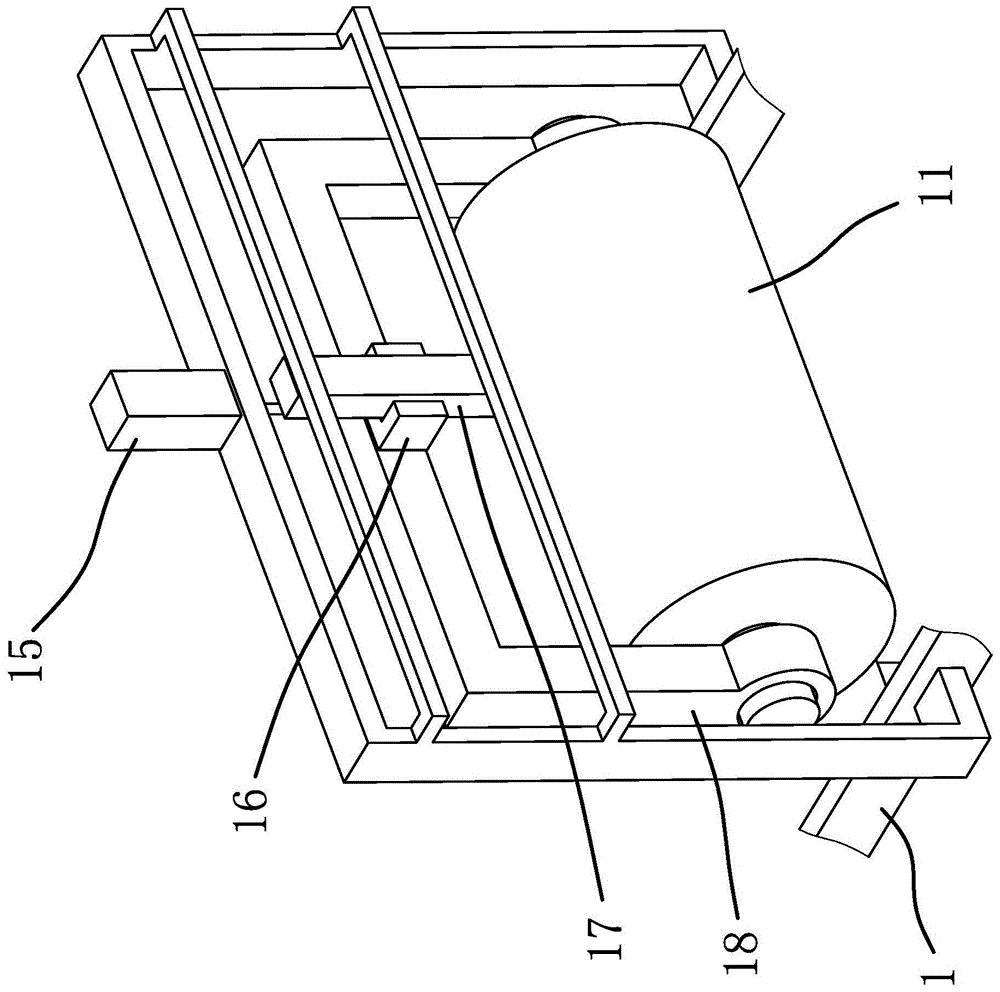

[0051] Such as figure 1 Shown, the padding equipment in step c comprises frame 1, first roller 10, second roller 12, the 3rd roller 11 a...

Embodiment 2

[0057] The preparation method of this blended interwoven cloth comprises the following steps:

[0058] A, take the required raw material by the weight part of above each component;

[0059] b. Add polytetrafluoroethylene concentrated dispersion, cross-linking agent, antistatic agent and antioxidant to the mixer, stirring time 8min, stirring speed 125r / min, prepared finishing solution;

[0060] c. Inject the finishing solution into the padding tank of the padding equipment, immerse the base cloth layer in the padding tank 14, and treat it with the padding process, the padding speed is 15m / min, and the finishing liquid layer is the protective layer;

[0061] d. Put the padded base fabric layer into an oven for drying treatment, the drying temperature is 125° C., and the drying time is 14 minutes to obtain the blended interwoven fabric.

[0062] Such as figure 1 Shown, the padding equipment in step c comprises frame 1, first roller 10, second roller 12, the 3rd roller 11 and ma...

Embodiment 3

[0068] The preparation method of this blended interwoven cloth comprises the following steps:

[0069] A, take the required raw material by the weight part of above each component;

[0070] b. Add the polytetrafluoroethylene concentrated dispersion, crosslinking agent, antistatic agent and antioxidant to the mixer, stir for 10 minutes, and stir at a speed of 150r / min to prepare the finishing solution;

[0071] c. Inject the finishing liquid into the padding tank of the padding equipment, dip the base cloth layer in the padding tank 14, and process it with the padding process, the padding speed is 20m / min, and the finishing liquid layer is the protective layer;

[0072] d. Put the padded base fabric layer into an oven for drying treatment at a drying temperature of 150° C. and a drying time of 18 minutes to obtain the blended interwoven fabric.

[0073] With this method, the protective layer is quickly fixed on the base cloth layer by padding, which replaces the previous spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com