System and method for producing fully-graphitized carbon product through waste cathode carbon blocks of electrolyzed aluminum

A technology for waste cathode carbon blocks and carbon products is applied in the field of aluminum electrolysis waste recycling, which can solve the problems of high processing cost and low economic added value of products, and achieves improving the degree of graphitization, increasing additional economic benefits, and reducing ash content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

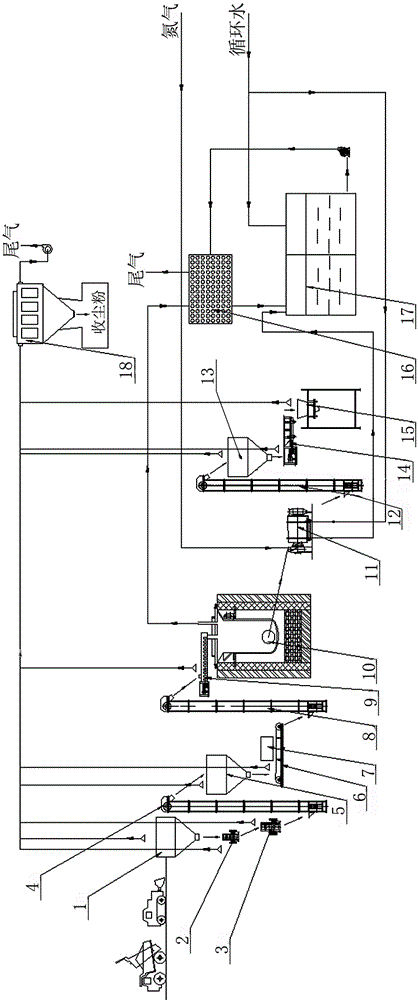

[0029] Embodiment 1: A system for producing fully graphitized carbon products with electrolytic aluminum waste cathode carbon blocks, including a crushing unit, a weighing and feeding unit, a calcination unit, a cooling unit, a packaging unit, an exhaust gas treatment unit and a dust collection unit; The crushing unit includes a raw material bin 1 , a jaw crusher 2 arranged at the outlet of the lower part of the raw material bin 1 , and a fine crusher 3 arranged at the outlet of the jaw crusher 2 .

[0030] The weighing and feeding unit includes No. 1 bucket elevator 4, intermediate silo 5, belt scale 6, No. 2 bucket elevator 8 and chain conveyor 9, the feeding port of No. 1 bucket elevator 4 and the crushing The discharge port of machine 3 is set correspondingly, the discharge port of No. 1 bucket elevator 4 is corresponding to the feed port setting of intermediate silo 5, one end of belt scale 6 is arranged below the discharge port of intermediate silo 5, and the other One e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com