Method for preparing high-concentration gradient AZO monocrystalline conductive thin film by direct current/radio frequency co-sputtering process

A conductive thin film and co-sputtering technology, which is applied in the field of preparation of bright conductive oxide thin films, can solve the problems of unfavorable large-scale industrialization, high production cost, and slow deposition speed, and achieve excellent crystal silicon passivation performance, low cost, and process easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) cleaning

[0033] Using monocrystalline silicon as the substrate, clean the monocrystalline silicon substrate by ultrasonically cleaning it in acetone for 10 minutes, then cleaning it in absolute ethanol for 10 minutes, and finally rinsing it with deionized water and drying it;

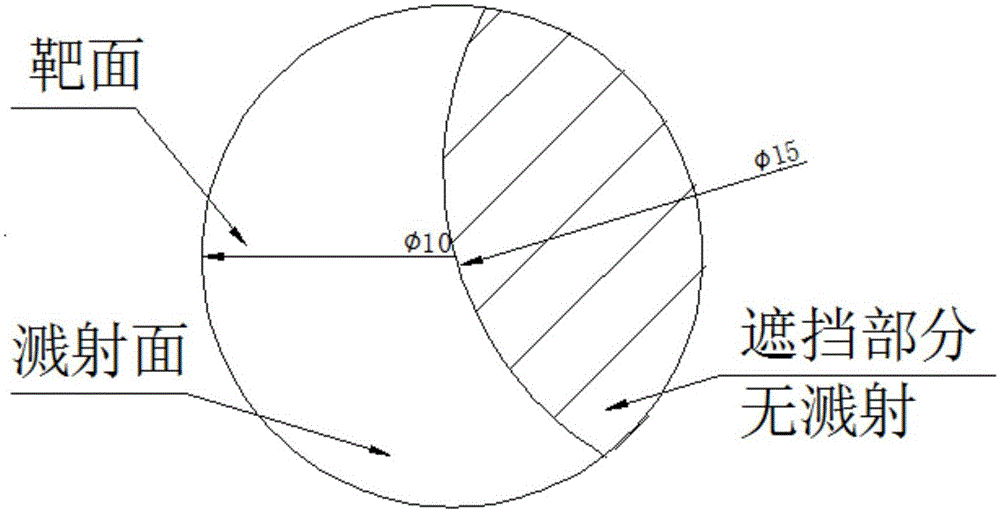

[0034] 2) Target and substrate installation

[0035] The targets used for sputtering are ZnO target (99.99% purity) and Al target (99.999% purity), the zinc oxide target is installed on the radio frequency target of the magnetron sputtering equipment, and the aluminum target is installed on the magnetron sputtering equipment On the DC target, install the monocrystalline silicon substrate on the sample stage at the top of the vacuum chamber of the magnetron sputtering equipment at the same time. During the loading process of loading the monocrystalline silicon substrate on the top of the vacuum chamber, ensure the cleanliness of the substrate surface;

[0036] 3) Sputtering deposition

[00...

Embodiment 2

[0039] 1) cleaning

[0040] Using monocrystalline silicon as the substrate, clean the monocrystalline silicon substrate, first ultrasonic cleaning in acetone for 15 minutes, then cleaning in absolute ethanol for 15 minutes, finally rinsing with deionized water, and drying;

[0041] 2) Target and substrate installation

[0042] The targets used for sputtering are ZnO target (99.99% purity) and Al target (99.999% purity), the zinc oxide target is installed on the radio frequency target of the magnetron sputtering equipment, and the aluminum target is installed on the magnetron sputtering equipment On the DC target, install the monocrystalline silicon substrate on the sample stage at the top of the vacuum chamber of the magnetron sputtering equipment at the same time. During the loading process of loading the monocrystalline silicon substrate on the top of the vacuum chamber, ensure the cleanliness of the substrate surface;

[0043] 3) Sputtering deposition

[0044] Gradient AZ...

Embodiment 3

[0046] 1) cleaning

[0047] Using monocrystalline silicon as the substrate, clean the monocrystalline silicon substrate by ultrasonically cleaning it in acetone for 20 minutes, then cleaning it in absolute ethanol for 20 minutes, and finally rinsing it with deionized water and drying it;

[0048] 2) Target and substrate installation

[0049] The targets used for sputtering are ZnO target (99.99% purity) and Al target (99.999% purity), the zinc oxide target is installed on the radio frequency target of the magnetron sputtering equipment, and the aluminum target is installed on the magnetron sputtering equipment On the DC target, install the monocrystalline silicon substrate on the sample stage at the top of the vacuum chamber of the magnetron sputtering equipment at the same time. During the loading process of loading the monocrystalline silicon substrate on the top of the vacuum chamber, ensure the cleanliness of the substrate surface;

[0050] 3) Sputtering deposition

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com