Method for rapid fractionation of triglyceride and diglyceride through Florisil adsorption method

A triglyceride and diglyceride technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of dry column hidden dangers, high technical requirements, cumbersome column installation, etc., and achieve high safety and low dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add florisil (25 g) and substrate (5 g) with a mass ratio of 5:1 (w / w) into a 150 mL ground-neck Erlenmeyer flask for 25 minutes of adsorption. Add 50mL of analytical grade n-hexane, place it on a magnetic stirrer, add a rotor, stir at 100r / min at room temperature for 10min, then filter, repeat elution for 9 times, collect the eluate of triglyceride, and spot the plate at the same time (using The developer is n-hexane: ether: acetic acid = 80:20:1, the same below) to confirm the presence or absence of diglyceride, remove n-hexane by rotary evaporation, and then pass nitrogen gas to completely remove the solvent to obtain triglyceride, and It is determined that its purity is 100mol%, and its yield is 86.50wt%. Next, add 60mL of n-hexane and diethyl ether solvent with a ratio of 16:1 (v / v) into the ground-necked flask, place it on a magnetic stirrer, add a rotor, stir at 100r / min for 10min, stir and elute at room temperature , repeated 3 times, and filtered to remove the...

Embodiment 2

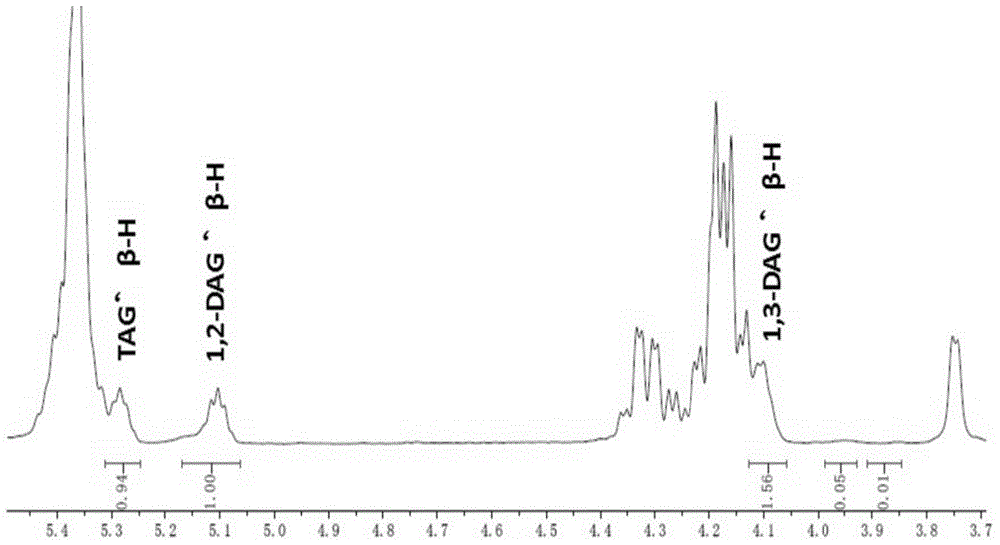

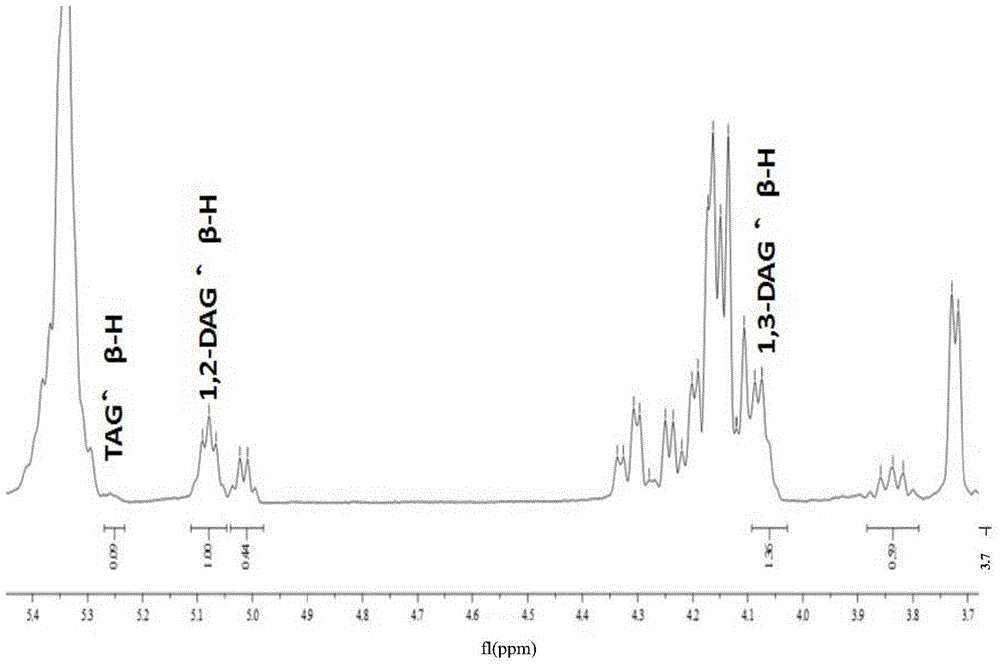

[0042] Add florisil (30 g) and substrate (5 g) with a mass ratio of 6:1 (w / w) into a 150 mL ground-neck Erlenmeyer flask for 25 minutes of adsorption. Add 40mL of analytical grade n-hexane, place it on a magnetic stirrer, add a rotor at 100r / min, stir at room temperature for 10min, filter, repeat elution for 11 times, collect the eluate of triglyceride, and spot the plate at the same time to confirm whether there is any Diacylglycerol appeared, and the n-hexane was removed by rotary evaporation to obtain triglyceride, and its purity was determined to be 100mol% ( figure 1 ), the yield was 85.13wt%. Next, add 60 mL of a mixed solvent of n-hexane and diethyl ether at a ratio of 18:1 (v / v) to a ground-necked flask, place it on a magnetic stirrer, add a rotor, stir at a speed of 100 r / min for 10 min, and wash at room temperature. Remove, repeat 3 times, filter to remove the mixture of diglyceride and triglyceride. Finally, 40 mL of analytically pure diethyl ether was added to th...

Embodiment 3

[0044] Add florisil (50 g) and substrate (5 g) with a mass ratio of 10:1 (w / w) into a 150 mL ground-neck Erlenmeyer flask for 25 minutes of adsorption. Add 100mL of analytically pure n-hexane, place it on a magnetic stirrer, add a rotor, stir at 100r / min at room temperature for 10min, then filter, repeat elution for 5 times, collect the eluate of triglyceride, and at the same time spot the plate to confirm that there is No diglycerides appeared, and the n-hexane was removed by rotary evaporation to obtain triglycerides, whose purity was determined to be 100mol%, and the yield was 82.27wt%. Next, add 50 mL of solvent with a ratio of n-hexane and diethyl ether of 20:1 (v / v) to the ground-necked flask, place it on a magnetic stirrer, add a rotor at a speed of 100 r / min and stir for 10 min, stir and elute at room temperature, repeat 4 Once, the mixture of diglycerides and triglycerides was removed by filtration. Finally, 100 mL of analytically pure diethyl ether was added to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com