Rapid tire pyrolysis system and method

A fast and tireless technology, used in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of complex process flow, complex fluidized bed process control, etc., to achieve temperature gradient, improve operation stability, pyrolysis oil Yield-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

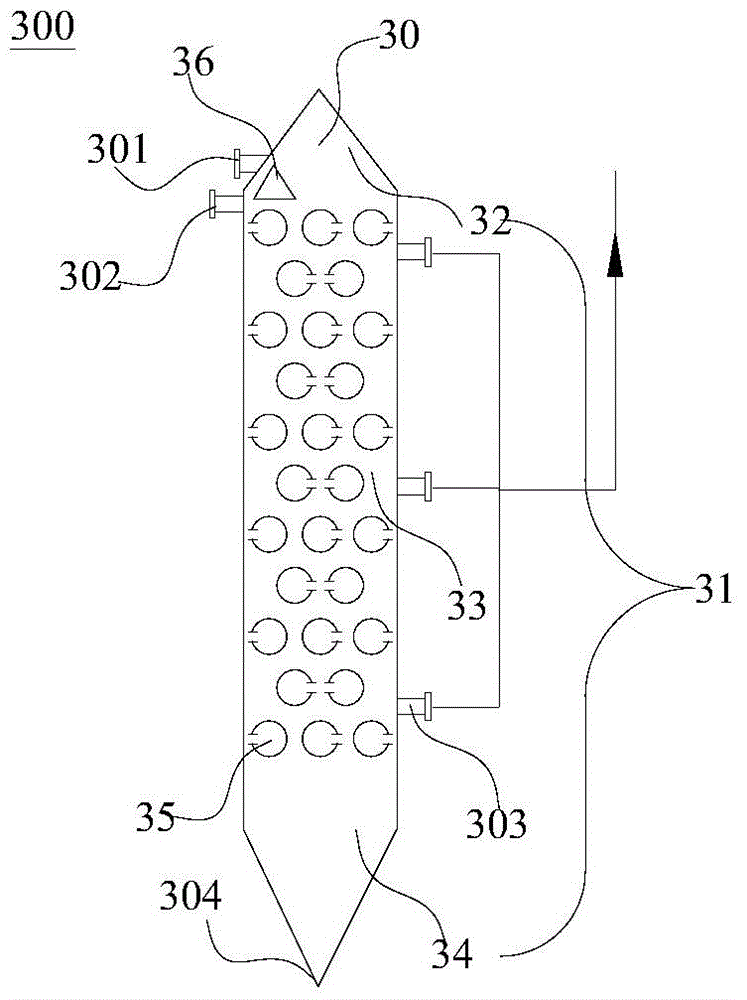

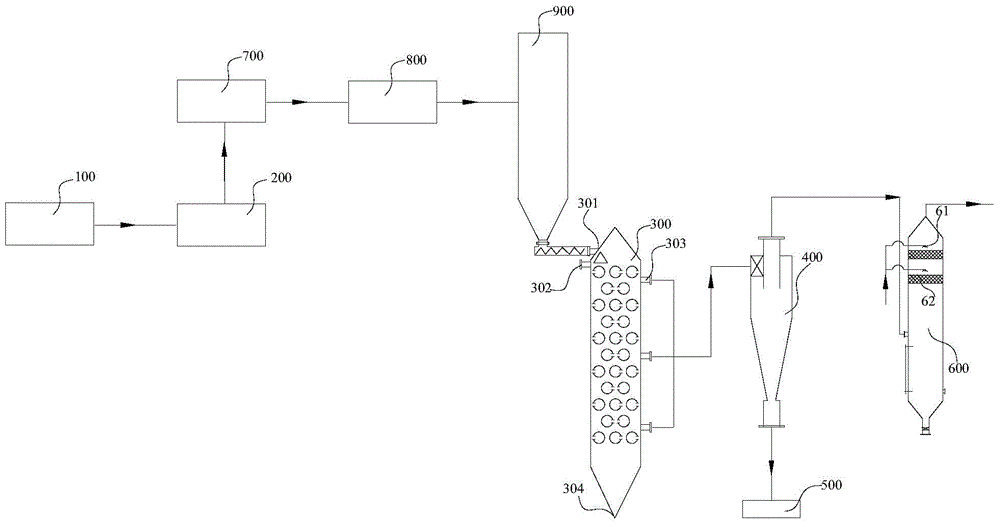

[0179] This embodiment 1 adopts Figure 1-6 The tire fast pyrolysis system, wherein, 15 layers of regenerative radiant tubes 35 are distributed at intervals along the height direction of the reactor body 30 in the pyrolysis zone 33, and adjacent regenerative radiant tubes are arranged along the horizontal and reactor body heights The two directions are spaced at the same interval and distributed in parallel. The regenerative radiant tube adopts a circular tube with a diameter of 100mm. The distance between the outer walls of adjacent radiant tubes in the horizontal direction is 100mm, and the outer wall distance between adjacent radiant tubes in the upper and lower layers is 200mm. Use the tire fast pyrolysis reaction system of the present invention to process waste tires, the particle size is below 1mm, the tire analysis data, process operation parameters and material balance are shown in Table 1-3, and the fast pyrolysis time is 15s. It can be seen from Table 3 that the yie...

Embodiment 2

[0188] This embodiment 2 adopts Figure 1-6 The tire rapid pyrolysis system, wherein, 8 layers of regenerative radiant tubes 35 are distributed at intervals along the height direction of the reactor body 30 in the pyrolysis zone 33, and adjacent regenerative radiant tubes are arranged along the horizontal and reactor body heights The two directions are spaced at the same interval and distributed in parallel. The regenerative radiant tube adopts a circular tube with a diameter of 500mm. The distance between the outer walls of adjacent radiant tubes in the horizontal direction is 500mm, and the outer wall distance between adjacent radiant tubes in the upper and lower layers is 500mm.

[0189] Utilize the tire fast pyrolysis reaction system of the present invention to process waste tires, the particle size is in the range below 0.8mm, the raw material of the tire to be pyrolyzed is the same as that of Example 1, and the process operation parameters and material balance are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com