Inferior coal decomposition equipment

A low-quality coal and equipment technology, applied in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve problems such as complex internal heating mechanism and distribution mechanism, difficult temperature control and adjustment, and normal production instability. Reasonable space arrangement, avoid incomplete decomposition, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

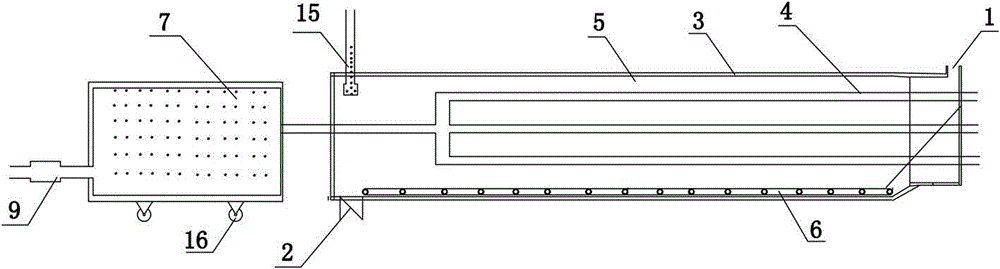

[0028] like figure 1 As shown, the present invention includes a closed kiln body 3 with a feed port 1 and a discharge port 2, the closed kiln body 3 is a fixed kiln body, and a plurality of high-temperature gas pipelines 4 are arranged in the fixed kiln body, and a plurality of high-temperature gas pipelines 4 Evenly arranged along the circumference of the fixed kiln body, a low-quality coal propulsion and decomposition channel 5 formed between a plurality of high-temperature gas pipelines 4 and the inner wall of the fixed kiln, and a low-quality coal propulsion mechanism 6 is set in the low-quality coal propulsion and decomposition channel 5, and the low-quality coal propulsion mechanism 6 is installed in the low-quality coal propulsion and decomposition channel 5 The coal propulsion mechanism 6 is a horizontal crawler belt, and the closed kiln body 3 is provided with a decomposition gas collection pipe 15 connected with the low-quality coal propulsion and decomposition channe...

Embodiment 2

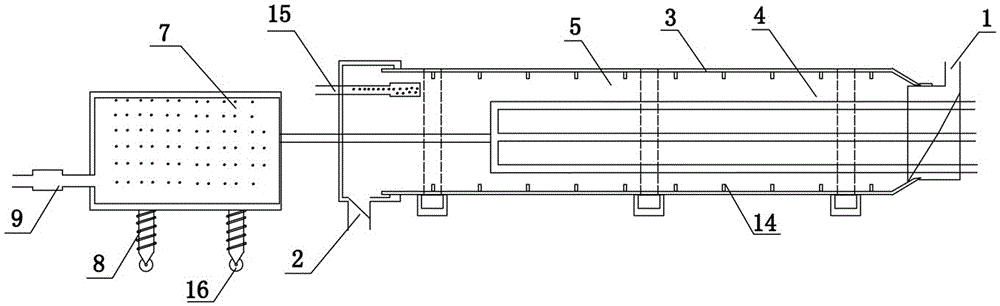

[0031] like figure 2As shown, the present invention includes a closed kiln body 3 with a feeding port 1 and a discharging port 2, the closed kiln body 3 is a rotary kiln body, and the rotary kiln body is provided with a high-temperature gas pipeline 4, and the high-temperature gas pipeline 4 is a plurality of , uniformly arranged along the circumference of the rotary kiln body, the low-quality coal formed between the high-temperature gas pipeline 4 and the inner wall of the rotary kiln pushes the decomposition channel 5, and the surface of the high-temperature gas pipeline 4 is provided with a heat dissipation plate (not shown) to improve the The rate of heat dissipation, the propelling plate 14 is arranged in the low-quality coal propelling and decomposing channel 5, and the rotary kiln body is combined with the propelling plate 14 arranged in the low-quality coal propelling and decomposing channel 5. The feed port 1 is slightly higher than the discharge port 2 to keep the r...

Embodiment 3

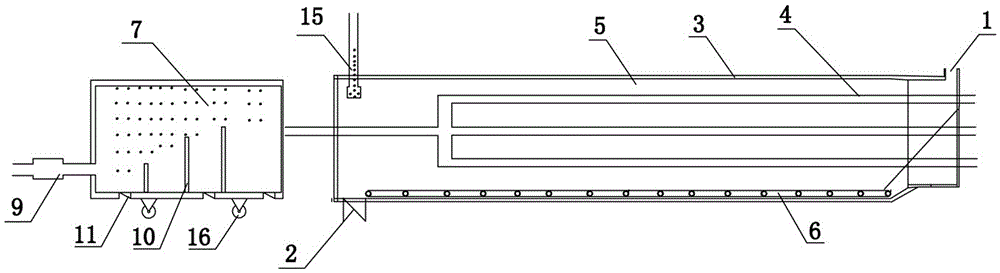

[0034] like image 3 As shown, the present invention includes a closed kiln body 3 with a feed port 1 and a discharge port 2, the closed kiln body 3 is a fixed kiln body, and the fixed kiln body is provided with a plurality of high-temperature gas pipelines 4, and a plurality of high-temperature gas pipelines 4 Evenly arranged along the circumference of the fixed kiln body, a low-quality coal propulsion decomposition channel 5 formed between a plurality of high-temperature gas pipes 4 and the inner wall of the fixed kiln body, a low-quality coal propulsion mechanism 6 is arranged in the low-quality coal propulsion decomposition channel 5, and a low-quality coal propulsion mechanism 6 is arranged in the low-quality coal propulsion decomposition channel 5. The coal propulsion mechanism 6 is a horizontal crawler, and the closed kiln body 3 is provided with a decomposed gas collection pipe 15 connected to the low-quality coal propulsion decomposition channel 5, which is used to col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com