Frosted metal protection ink

A technology for protecting ink and frosting, applied in the direction of ink, household appliances, application, etc., can solve the problems of long time for alkali washing ink, poor adhesion of alkali washing printing and frosted ink, etc., so as to shorten the deinking time and improve the adhesion. , the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation:

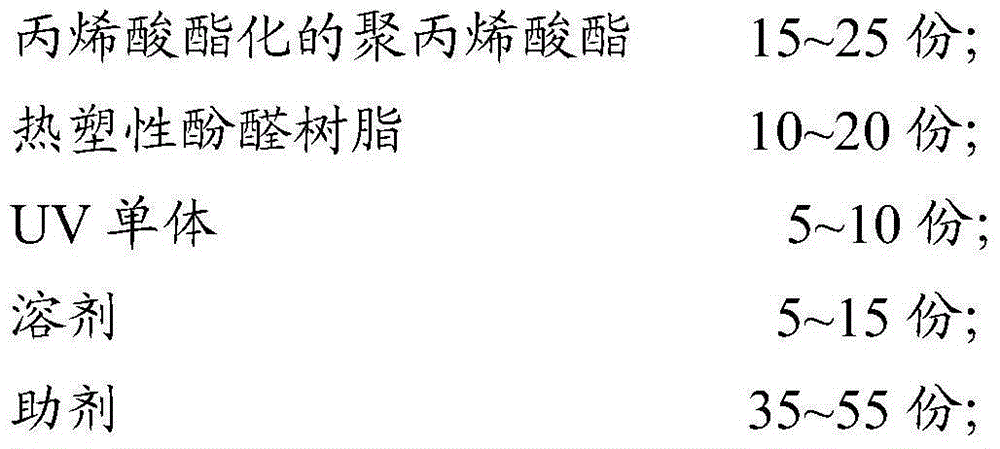

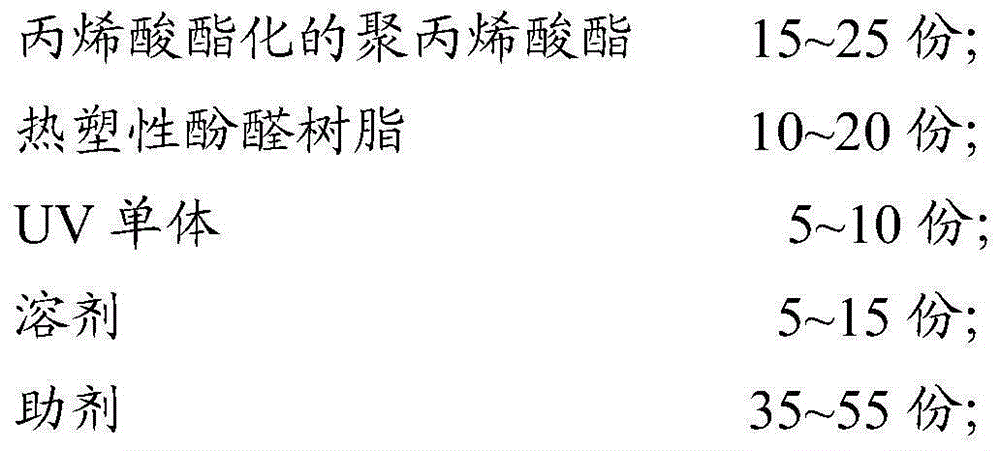

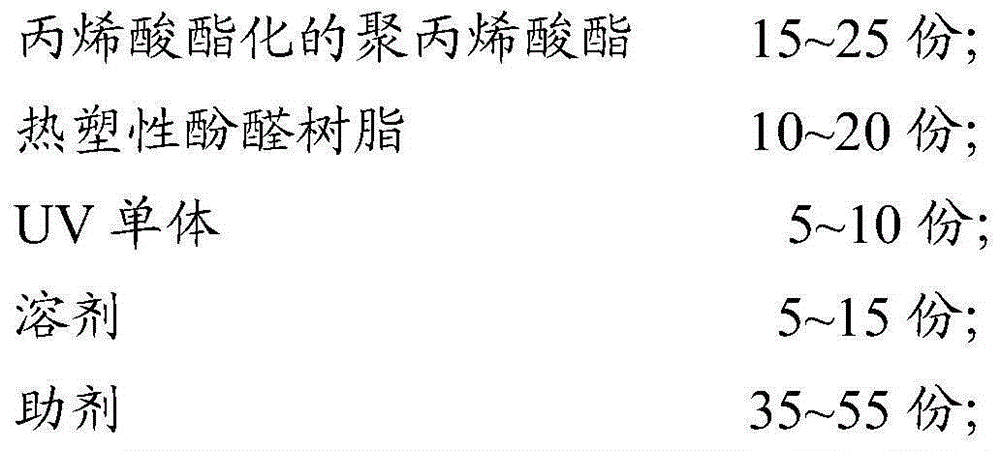

[0044] 20 parts by weight of acrylated polyacrylate (S2510, Zhanchen Coatings; acid value 80-100mgKOH / g, viscosity 40000-60000cps (25°C)), 5 parts by weight of HDDA, 20 parts by weight of a compound having the formula (I ) structure of thermoplastic phenolic resin (polymerization degree 4-10), 10 parts by weight of ethanol, 1 part by weight of anti-settling agent (A-200, Degussa), 0.3 parts by weight of defoamer (BYK-052, Germany Bi Ke), 0.3 parts by weight of leveling agent (BKY306, Bi Ke, Germany), 1 part by weight of dispersant (EFKA-4010, Efka auxiliary agent), 4 parts by weight of photoinitiator-1173, 1 part by weight Photoinitiator-184, 5000 mesh calcium carbonate of 37.4 parts by weight.

[0045] preparation:

[0046] In the mixer, first add ethanol and HDDA, then add phenolic resin, after stirring at high speed for 15 minutes, then add acrylated polyacrylate, dispersant, anti-settling agent, defoamer, photoinitiator and leveling agent in sequenc...

Embodiment 2

[0048] Preparation:

[0049] 25 parts by weight of acrylated polyacrylate (S2510, Zhanchen Paint; acid value 80-100mgKOH / g, viscosity 40000-60000cps (25°C)), 5 parts by weight of HDDA, 15 parts by weight of ) structure of thermoplastic phenolic resin (polymerization degree 4 ~ 10), 8 parts by weight of ethanol, 1 part by weight of anti-settling agent (M5, Cabot), 0.3 parts by weight of defoamer (BYK-052, German BYK ), the leveling agent (BKY306, Bicker, Germany) of 0.3 parts by weight, the dispersant (BYK-164, Bicker, Germany) of 1 part by weight, the photoinitiator-1173 of 4 parts by weight, the photoinitiator of 1 part by weight -184, 39.4 parts by weight of 5000 mesh calcium carbonate.

[0050] preparation:

[0051] In the mixer, first add ethanol and HDDA, then add phenolic resin, after stirring at high speed for 15 minutes, then add acrylated polyacrylate, dispersant, anti-settling agent, defoamer, photoinitiator and leveling agent in sequence , after stirring evenly, ...

Embodiment 3

[0053] Preparation:

[0054] 23 parts by weight of acrylated polyacrylate (S2510, Zhanchen Paint; acid value 80-100mgKOH / g, viscosity 40000-60000cps (25°C)), 5 parts by weight of HDDA, 2 parts by weight of DPGDA, 17 parts by weight Parts of thermoplastic phenolic resin (polymerization degree 4~10) with formula (I) structure, 10 parts by weight of ethanol, 1 part by weight of anti-settling agent (A-200, Degussa), 0.3 parts by weight of defoamer (BYK-052, Bicker, Germany), 0.3 parts by weight of leveling agent (BKY306, Bicker, Germany), 1 part by weight of dispersant (EFKA-4010, Efka auxiliary agent), 4 parts by weight of photoinitiator -1173, 1 part by weight of photoinitiator -184, 35.6 parts by weight of 5000 mesh calcium carbonate.

[0055] preparation:

[0056] In the blender, first add ethanol, DPGDA and HDDA, then add phenolic resin, after stirring at high speed for 15 minutes, then add acrylated polyacrylate, dispersant, anti-settling agent, defoamer, photoinitiator an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com