Preparation process of photo-initiator bis(2,4,6-trimethylbenzoyl)phenylphosphine oxide

A technology of trimethylbenzoyl and trimethylbenzoyl, applied in the field of preparation technology of photoinitiator phenylphosphine oxide, can solve the problems of easy spontaneous combustion, inconvenient feeding of solid materials, high price of lithium aluminum hydride, etc. Ease of operation, lower production costs, and the effect of simplifying separation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

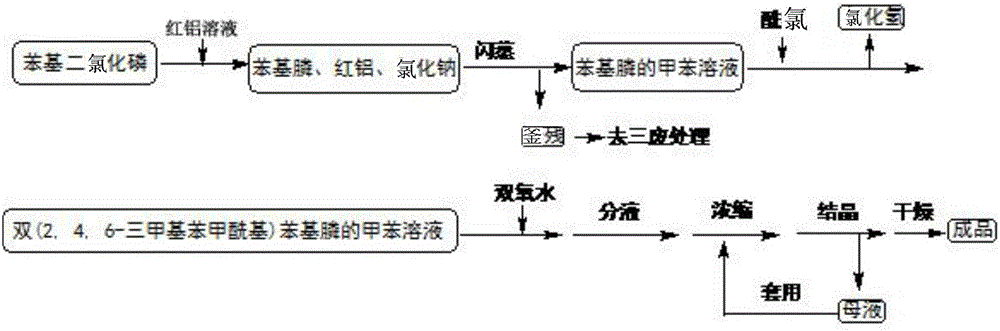

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation technology of two (2,4,6-trimethylbenzoyl) phenyl phosphine oxides of photoinitiator, concrete steps are as follows:

[0028] 1) Under nitrogen protection, add 1L toluene and 300mL red aluminum solution into a 2L reaction kettle, cool down to -10±5°C, add 179g of phenylphosphine dichloride dropwise, and keep the system temperature at -10±5°C, After the dropwise addition, warm up to room temperature, heat and reflux for 8 hours, GC detects that the reaction of phenylphosphine dichloride is complete, and obtains a toluene solution containing sodium chloride, excess red aluminum, and phenylphosphine, and then pours the toluene solution into a continuous flash Flash evaporation is carried out in the evaporator, the flash pressure is controlled at 0.1kPa, the gas phase temperature is controlled at 60±5°C, sodium chloride and excess red aluminum are removed to obtain a toluene solution containing phenylphosphine (mass fraction is 8%) 1.1L;

[0029] 2) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com