Treatment technology of reinjecting heavy oil wastewater into low-permeability reservoir

A technology of heavy oil sewage and treatment process, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, mining wastewater treatment, etc. It can solve the problem that the effluent cannot meet the water quality requirements of low-permeability oilfields, and there is no bacteria removal process , lengthy treatment process and other issues, to achieve the effect of prolonging the cleaning cycle and service life, stable treatment effect, and reasonable treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In the heavy oil sewage of an oilfield A, the raw water contains 212.85 mg / L oil, 1356.0 mg / L COD, 59.2 mg / L suspended solids, 97.56 μm median suspended solids particle size, and 0.202 mm / a corrosion rate. Utilize the method of the present invention to process and reinject the low-permeability oil field, the concrete steps are as follows:

[0034] (1) Multi-effect degreasing treatment

[0035] The heavy oily sewage first enters the multi-effect degreasing device, and the multi-effect degreasing device is sequentially equipped with a gravity settling area, a coalescence degreasing area, and an inclined plate settling area; the heavy oily sewage first undergoes preliminary gravity separation in the gravity settling area to remove floating Oil and dispersed oil with larger particle size; then, the sewage enters the coalescing and degreasing area, relying on the coarse-grained materials in it, through wetting and collision, the oil droplets become larger; finally, the sewag...

Embodiment 2

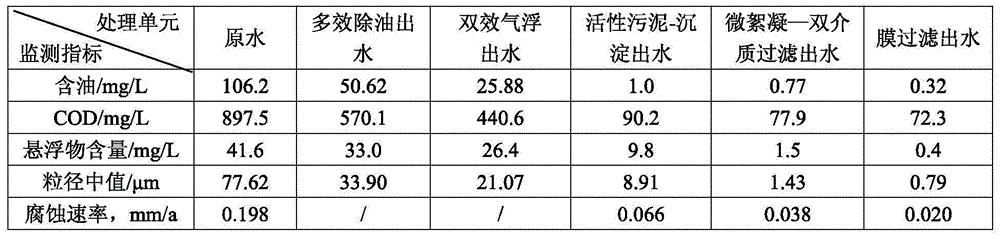

[0053] In the heavy oil sewage of an oilfield B, the raw water contains 106.2mg / L oil, 897.5mg / L COD, 41.6mg / L suspended solids, 77.62μm median particle size of suspended solids, and 0.198mm / a corrosion rate. Utilize the method of the present invention to process and reinject the low-permeability oil field, the concrete steps are as follows:

[0054] (1) Multi-effect degreasing treatment

[0055] The heavy oily sewage first enters the multi-effect degreasing device, and the multi-effect degreasing device is sequentially equipped with a gravity settling area, a coalescence degreasing area, and an inclined plate settling area; the heavy oily sewage first undergoes preliminary gravity separation in the gravity settling area to remove floating Oil and dispersed oil with larger particle size; then, the sewage enters the coalescing and degreasing area, relying on the coarse-grained materials in it, through wetting and collision, the oil droplets become larger; finally, the sewage en...

Embodiment 3

[0073] In the heavy oil sewage of an oilfield E, the raw water contains 80.42mg / L oil, 674.5mg / L COD, 39.7mg / L suspended solids, 67.24μm median particle size of suspended solids, and 0.189mm / a corrosion rate. Utilize the method of the present invention to process and reinject the low-permeability oil field, the concrete steps are as follows:

[0074] (1) Multi-effect degreasing treatment

[0075] The heavy oily sewage first enters the multi-effect degreasing device, and the multi-effect degreasing device is sequentially equipped with a gravity settling area, a coalescence degreasing area, and an inclined plate settling area; the heavy oily sewage first undergoes preliminary gravity separation in the gravity settling area to remove floating Oil and dispersed oil with larger particle size; then, the sewage enters the coalescing and degreasing area, relying on the coarse-grained materials in it, through wetting and collision, the oil droplets become larger; finally, the sewage en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com