Method of treating piggery methane fluid by utilizing composite photosynthetic bacteria

A treatment method and compound light technology, which is applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve rare research problems and achieve the effect of easy operation and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

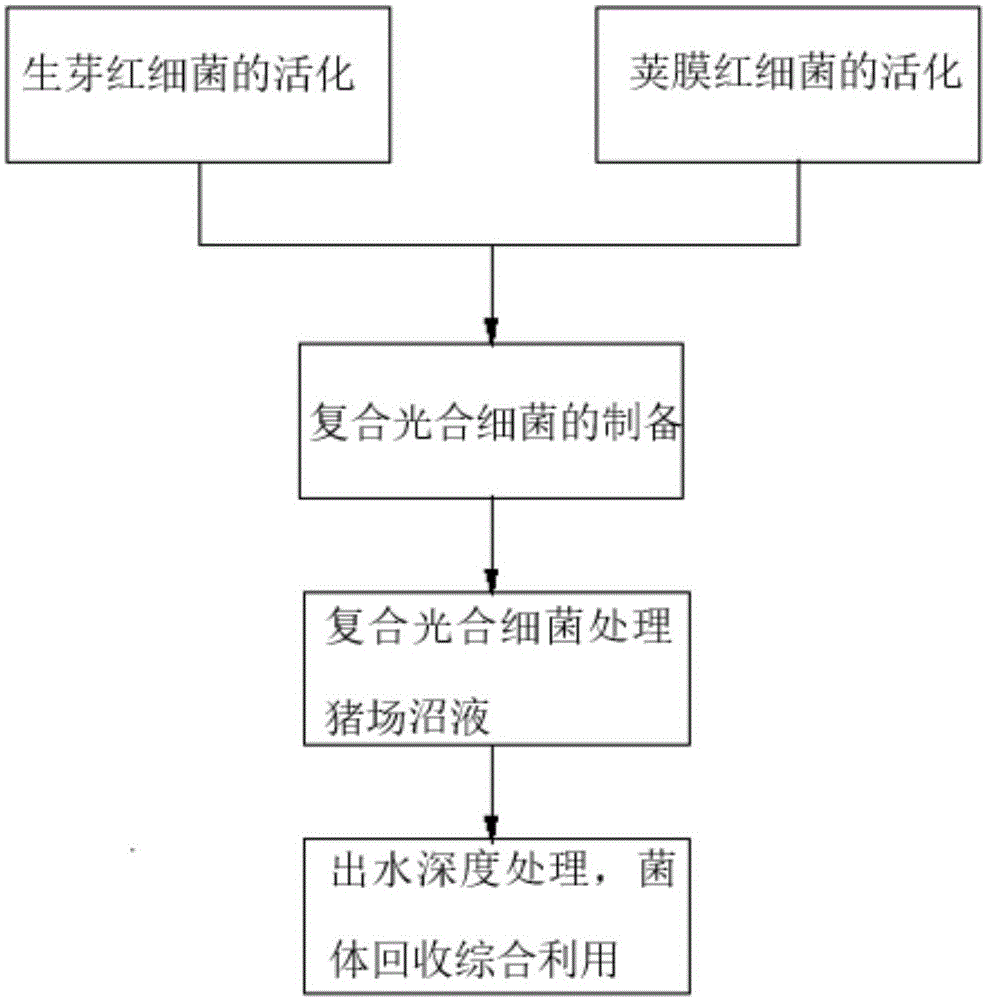

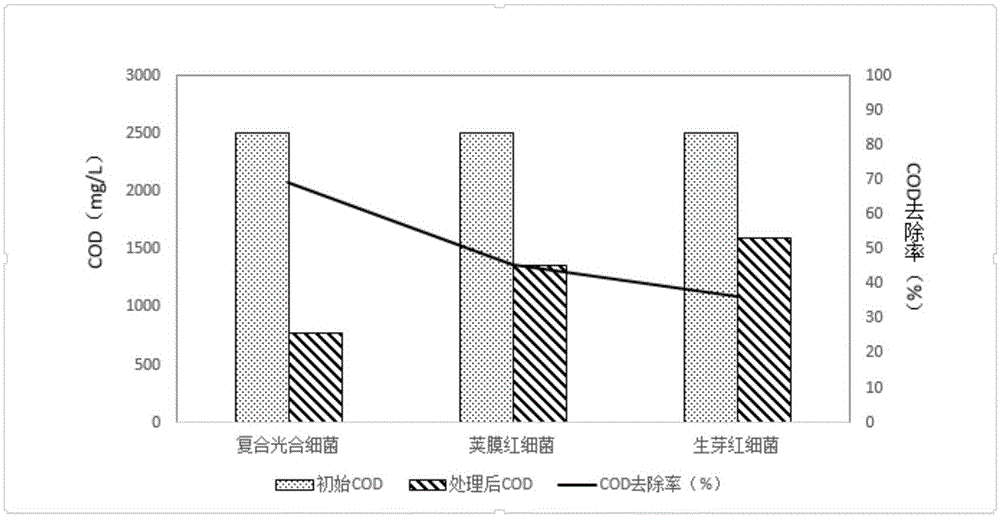

[0022] Example 1: Treatment of pig farm biogas slurry by composite photosynthetic bacteria

[0023] Step A: preparation of composite photosynthetic bacteria, budding rhodobacteria and capsulated rhodobacteria are cultivated according to the following steps:

[0024] (1) budding rhodobacteria and capsular rhodobacteria on the slant culture medium of purified culture are picked 1~2 rings respectively with inoculation loop, respectively inoculate in two Erlenmeyer flasks that the bacterium activation liquid culture medium of 100ml is housed in two bottles, Under the conditions of pH 7.0, light intensity 3000 lux, and temperature 30°C, static culture was carried out for 4 days to obtain one bottle of liquid culture solution containing activated budding rhodobacter and one bottle of liquid culture solution containing activated capsulated rhodobacter.

[0025] Wherein, the composition of the bacterial activation liquid medium is as follows: 10g / L peptone, 6g / L yeast extract powder, ...

Embodiment 2

[0030] Embodiment 2: Rhodobacter capsularis processing swine farm biogas slurry

[0031] This case is a comparative test of Case 1. Only Rhodobacter capsulata is used to treat pig farm biogas slurry, and other treatment steps are the same.

[0032] Step A: the preparation of photosynthetic bacteria, the capsulated rhodobacter is cultivated according to the following steps:

[0033] (1) Pick 1 to 2 loops of capsulated rhodobacteria on the slant medium of purified culture with an inoculation loop, inoculate into a Erlenmeyer flask with 100ml of bacterial activation liquid medium in a bottle, at pH7.0, light intensity Under the conditions of 3000 lux and temperature of 30° C., static culture was carried out for 4 days to obtain a bottle of liquid culture solution containing activated rhodobacter capsulata.

[0034] Wherein, the composition of the bacterial activation liquid medium is as follows: 10g / L peptone, 6g / L yeast extract powder, 1.2g / L glucose, the medium was sterilized ...

Embodiment 3

[0039] Example 3: Rhodobacter budding bacteria treatment of swine farm biogas slurry.

[0040] This case is a comparative test of Case 1 and Case 2. Only rhodobacter budding was used to treat pig farm biogas slurry, and other treatment steps were the same.

[0041] Step A: the preparation of photosynthetic bacteria, the budding rhodobacter is cultivated according to the following steps:

[0042] (1) Pick 1 to 2 rings of budding rhodobacteria on the slant medium of purified culture with an inoculation loop, inoculate into a Erlenmeyer flask with 100ml of bacterial activation liquid medium in a bottle, at pH7.0, light intensity Under the conditions of 3000 lux and a temperature of 30° C., static culture was carried out for 4 days to obtain a bottle of liquid culture solution containing activated bud-forming rhodobacteria.

[0043] Wherein, the composition of the bacterial activation liquid medium is as follows: 10g / L peptone, 6g / L yeast extract powder, 1.2g / L glucose, the medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com