3D precision shaping method of conformal cooling structure of injection mold

A technology of conformal cooling and injection molding, which is applied in the field of mold manufacturing, can solve problems such as low strength of welded joints, influence on surface accuracy, and large amount of welding deformation, and achieve high production efficiency, low production cost, high strength and precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Using Cu as the 3D precision molding method of the injection mold conformal cooling structure of the diffusion welding intermediate layer, the steps are as follows:

[0042] The type of die steel is P20.

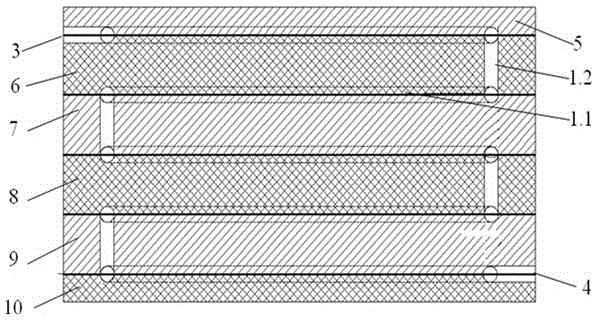

[0043] Aiming at the surface profile of the injection mold cavity, based on the heat transfer calculation, a three-dimensional model of the conformal cooling channel for efficient heat exchange is established, as follows: figure 1 shown, according to figure 1 The semicircular mold cavity 2 establishes a three-dimensional model of the conformal cooling channel. The cooling medium enters from the inlet 3, realizes a three-dimensional serial flow channel along the conformal cooling channel (1.1 and 1.2), and finally reaches the cooling medium outlet 4.

[0044] Based on the basic principle of easy processing, the layer structure of the three-dimensional model of the conformal cooling channel is divided, as follows figure 2As shown, the entity is divided into layer st...

Embodiment 2

[0053] The 3D precision molding method of the conformal cooling structure of the injection mold using Au as the diffusion welding intermediate layer differs from Example 1 in that:

[0054] The middle layer of diffusion welding is 5mm thick Au foil.

[0055] Place the assembled parts to be welded in a vacuum diffusion welding furnace, close the furnace door, and pump the furnace body to a vacuum degree of 10 -3 Pa. Then raise the welding temperature to 1094°C, pressurize at 0.5MPa, and keep the temperature for 1h. After the heat preservation is over, the pressure is released, and the weldment is cooled with the furnace. Realize the precise and high-strength connection of each layer structure.

Embodiment 3

[0057] Adopting Mn as the 3D precision molding method of the injection mold conformal cooling structure of the diffusion welding intermediate layer, the difference from Example 1 is:

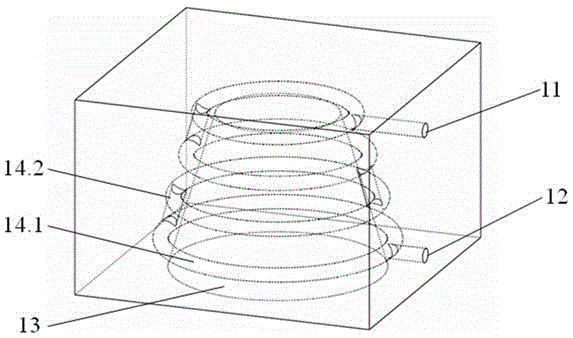

[0058] Aiming at the contour of the cavity surface of the injection mold, based on the heat transfer calculation, a three-dimensional model of the conformal cooling channel for efficient heat exchange is established, as follows: image 3 shown, according to image 3 A three-dimensional model of the conformal cooling channel is established in the circular mold cavity 13 . The cooling medium enters from the inlet 11 , realizes a three-dimensional serial flow channel along the conformal cooling channels ( 14.1 and 14.2 ), and finally reaches the cooling medium outlet 12 .

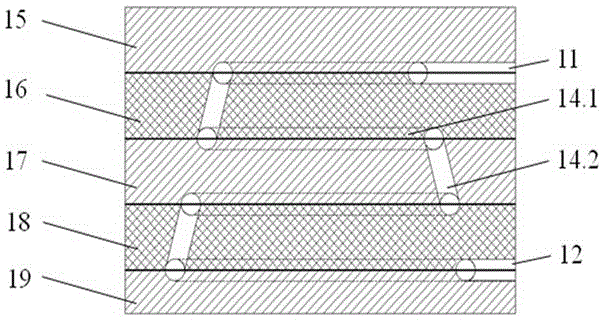

[0059] Based on the basic principle of easy processing, the layer structure of the three-dimensional model of the conformal cooling channel is divided. Specific as Figure 4 shown. Divide the entity into layer structures alo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com