Parallel-type oval vibration turning device applicable to vertical type excircle machining

An elliptical vibration and parallel technology, which is applied in the direction of driving devices, turning equipment, turning equipment, etc., can solve the problems of high requirements for machine tools that can be matched with processing, limited range of parameter adjustment, and difficulty in achieving high-frequency cutting. High-frequency cutting, small overall height and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

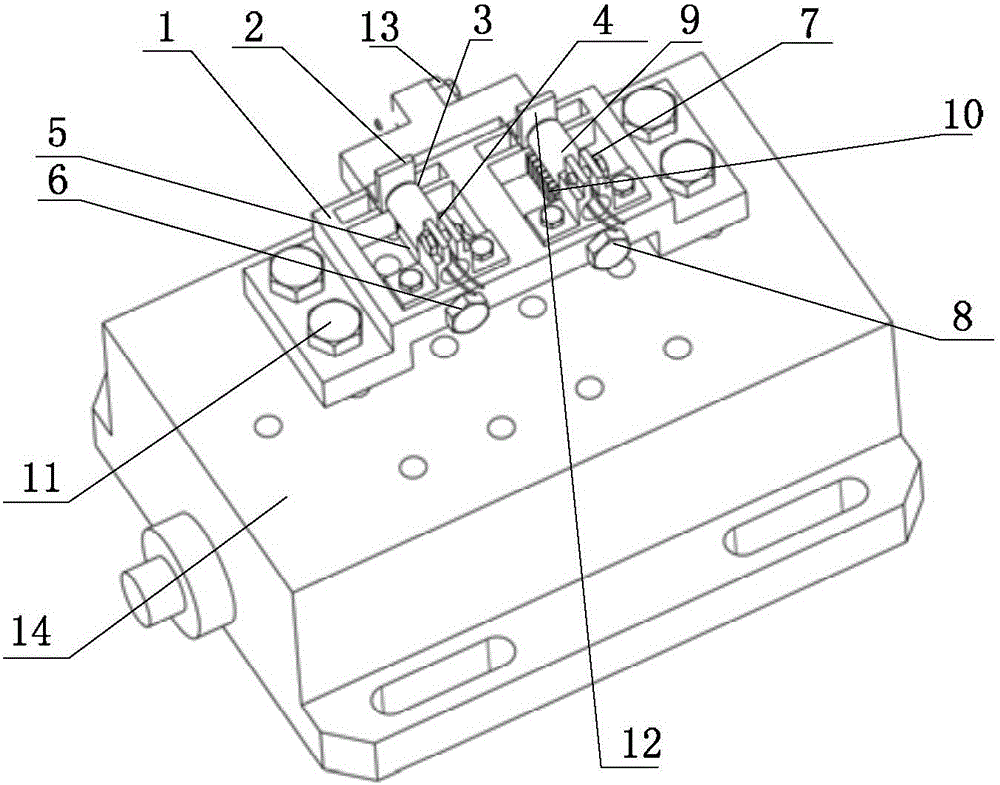

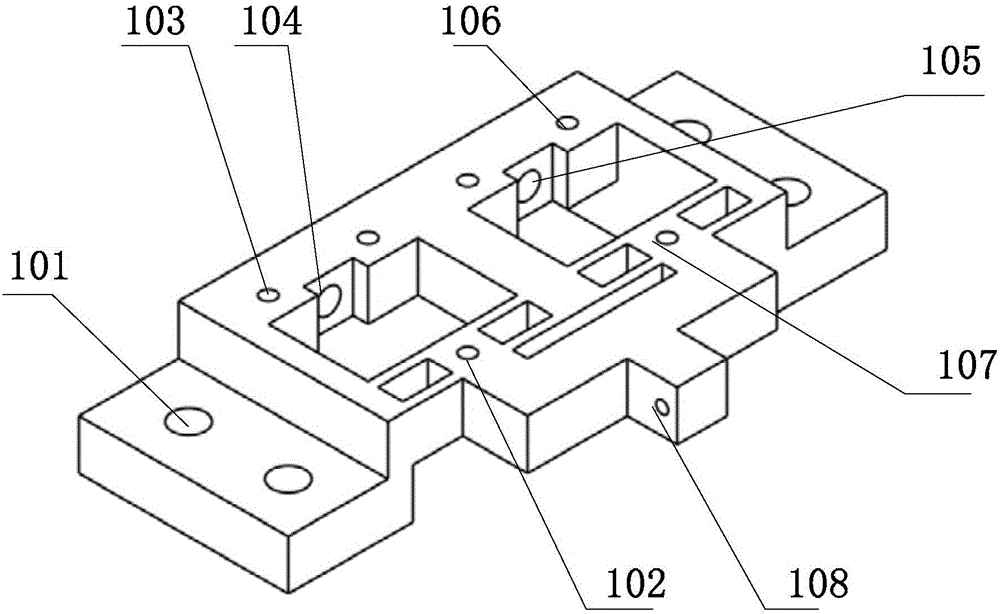

[0018] The piezoelectric stack one 5 is connected to the parallel integrated hinge base 1 through the pre-tightening screw one 6 installed on the hole five 105, and the second piezoelectric stack 10 is connected to the parallel integrated hinge base 1 through the pre-tightening screw two 8 installed on the hole four 104. Type hinge base 1 is connected, the displacement measurement baffle 1 is installed on the hole 7 107 of the parallel integrated hinge base 1 through fastening screws, and the displacement measurement baffle 2 12 is installed on the hole 1 of the parallel integrated hinge base 1 through fastening screws On the second 102, the capacitive displacement sensor one 3 and the capacitive displacement sensor two 9 are installed on the displacement sensor holder one 4 and the displacement sensor holder two 7 respectively, and the displacement sensor holder one 4 and the displacement sensor holder two 7 respectively Installed on hole six 106 and hole three 103 of the para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com